Flying capacitive series battery pack voltage detection device and control method

A series battery pack and voltage detection technology, which is applied in the direction of measurement using digital measurement technology, can solve the problems of power lithium battery pack equalization effect weakening, battery pack measurement accuracy is low, and battery service life is reduced, so as to solve the problem of resistance voltage division Low precision, low power consumption, and the effect of preventing high voltage shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

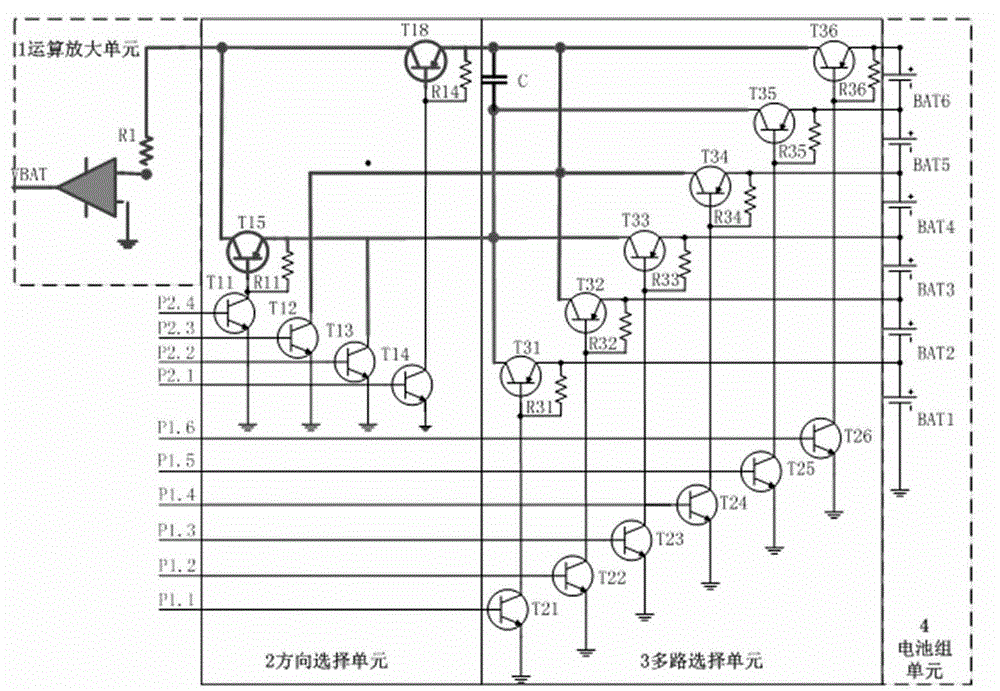

[0018] figure 1 It is a circuit diagram of a battery voltage detection circuit, and the implementation method of the present invention is illustrated by taking 6 lithium-ion batteries connected in series as an example, and the circuit is applicable to more battery pack applications.

[0019] The battery voltage detection circuit is composed of an operational amplifier unit, a direction selection unit, a multi-channel selection unit, and a battery pack unit; the operational amplifier unit mainly completes the functions of impedance matching and signal amplification.

[0020] The direction correction circuit is composed of T11-T14, T15, T18, R11, R14, which mainly completes the functions of direction switching and isolation of flying capacitors.

[0021] The multi-channel selection unit is composed of T21-T26, T31-T36, and R31-R34, which mainly completes the signal gating of single-cell battery voltage measurement. The connection method takes T36, T26, and R36 as examples to il...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com