Gold finger manufacturing method for reducing oxidation of gold finger

A production method and technology of gold fingers, which are applied in printed circuit manufacturing, cleaning/polishing of conductive patterns, secondary processing of printed circuits, etc., can solve the problems of gold finger doping, gold finger oxidation, etc. The generation of copper dust and the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

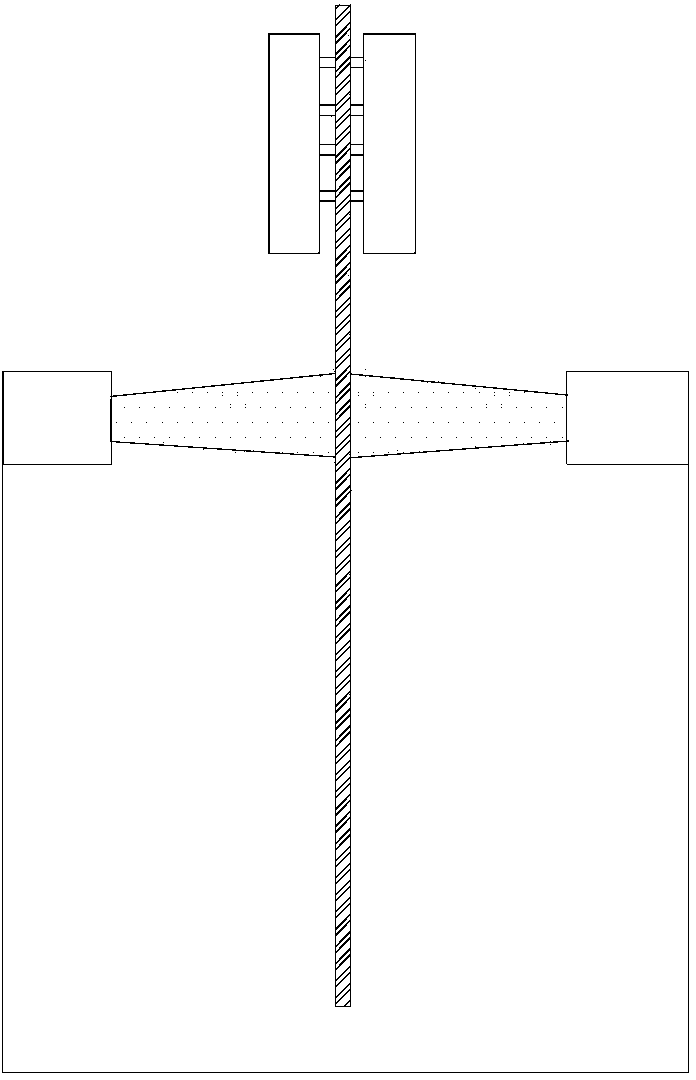

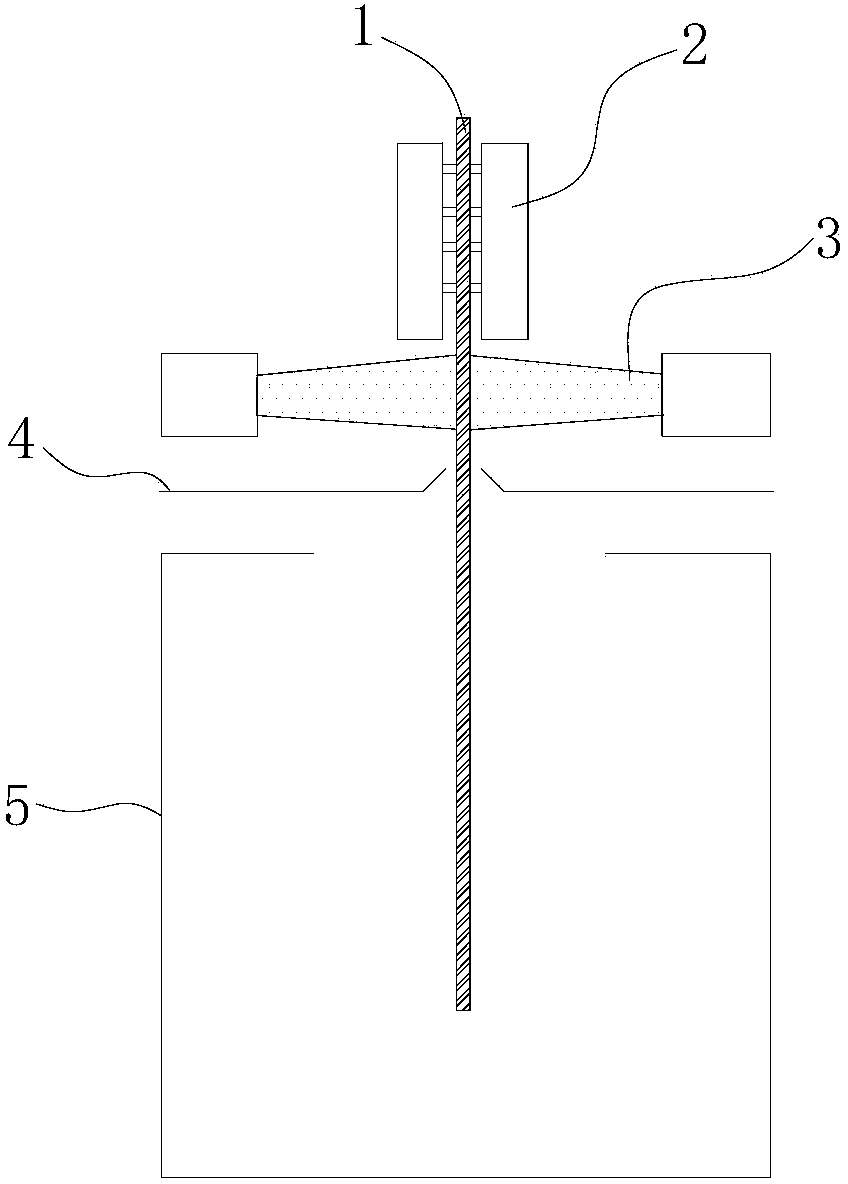

Image

Examples

Embodiment 1

[0020] This embodiment provides a gold finger manufacturing method for reducing gold finger oxidation, which specifically includes the following steps:

[0021] (1) Production of circuit boards (outer circuit and solder resist layer were produced on the multi-layer board)

[0022] First, as in the circuit board production process of the prior art, the raw materials of each layer of circuit board are cut to obtain the substrate, and then the inner layer pattern is transferred to each substrate to form the inner layer circuit circuit, and then the circuit boards of each layer are laminated to form Multi-layer circuit board, and then drill the multi-layer circuit board. After drilling, place the multi-layer circuit board in the electroplating tank for copper sinking treatment and full-board electroplating treatment. Then carry out outer layer pattern transfer, pattern electroplating, film stripping, etching and tin stripping in sequence, so that the outer layer circuit lines are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com