Polishing composition and fabrication method of substrate using same

A technology of composition and metal compound, which is applied in the direction of polishing composition containing abrasives, manufacturing tools, grinding devices, etc., can solve the problems of rising grinding costs, surface defects, orange peel, etc., and achieve the effect of suppressing surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

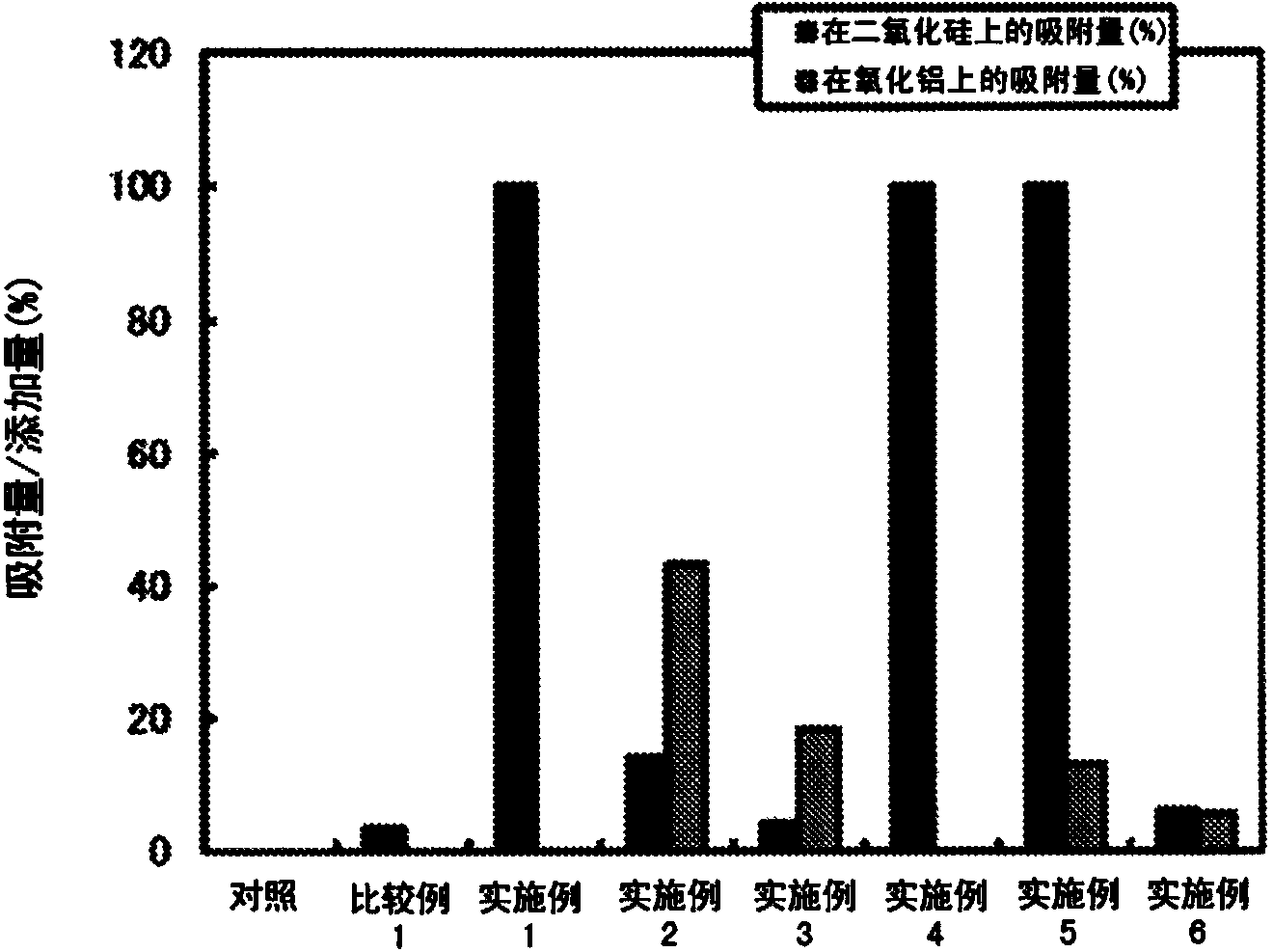

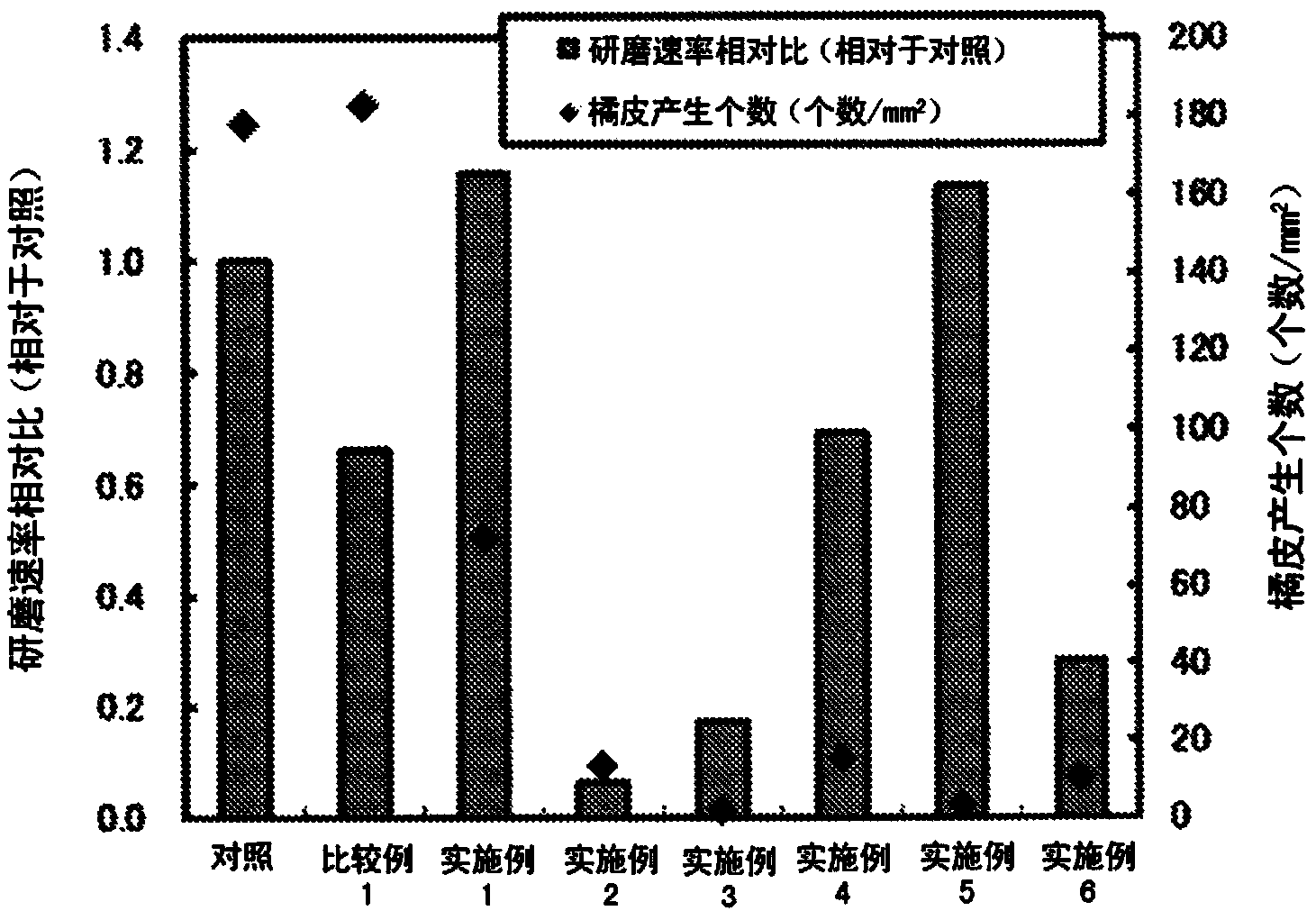

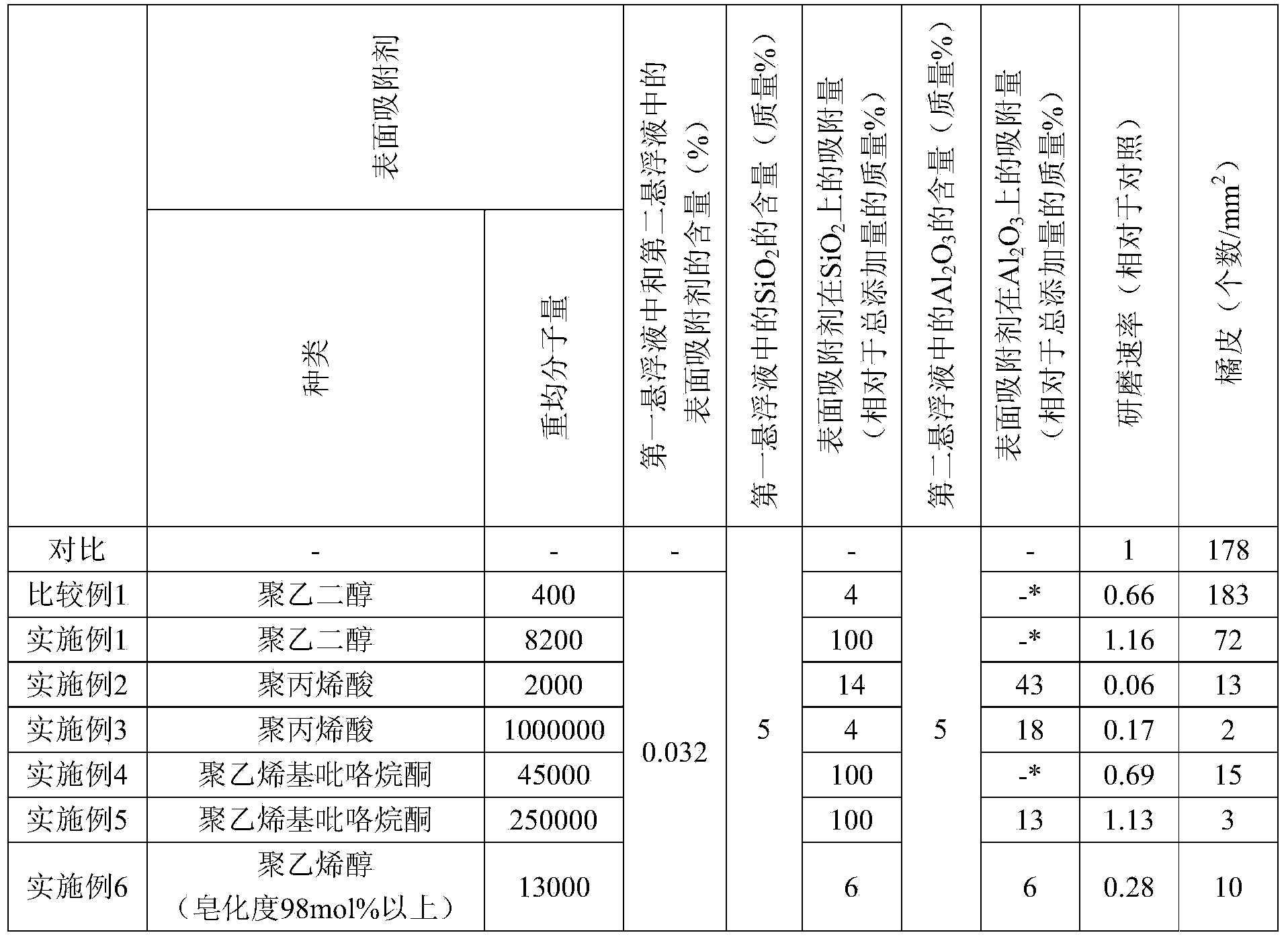

[0071] Next, examples and comparative examples are given to describe the above-mentioned embodiment in more detail.

[0072] (Preparation of Polishing Composition)

[0073] A colloidal silica sol containing colloidal silica having an average primary particle diameter of 80 nm was diluted with water, and various surface adsorbents were added thereto. Then, the pH was adjusted to 7 using nitric acid or potassium hydroxide (pH adjuster), thereby preparing polishing compositions of Examples 1 to 6 and Comparative Example 1. The types and weight-average molecular weights of the surface adsorbent contained in each polishing composition are shown in the "Surface Adsorbent" column of Table 1. In the polishing compositions of Examples 1 to 6, the colloidal silica content was 5% by mass and the surface adsorbent content was 0.032% by mass.

[0074] A colloidal silica sol containing colloidal silica having an average primary particle diameter of 80 nm was diluted with water, and its pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com