Polishing material for synthetic quarts glass substrate and method for polishing synthetic quarts glass substrate

一种玻璃基板、合成石英的技术,应用在含研磨剂的抛光组合物、研磨装置、研磨机床等方向,能够解决石英玻璃基板表面划痕等问题,达到抑制缺陷产生、反应性提高、研磨速度提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

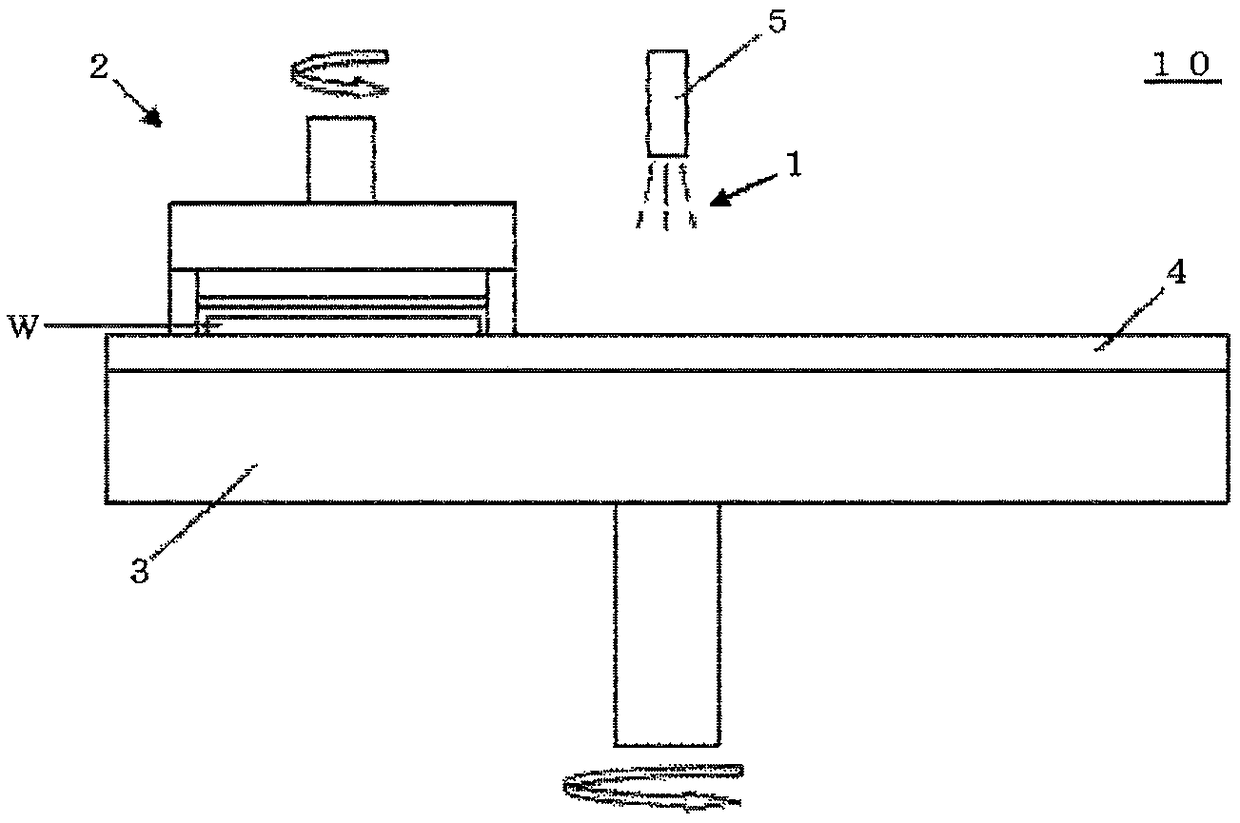

Method used

Image

Examples

preparation example Construction

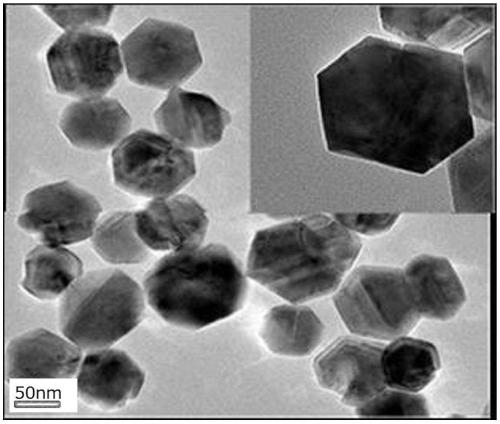

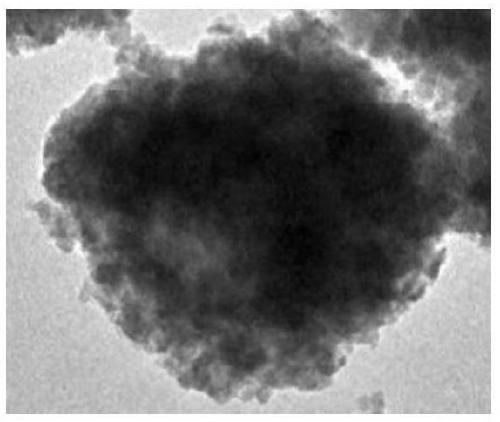

[0054] The method for producing the above-mentioned wet ceria matrix particles is not particularly limited, and the following methods can be used. First, a cerium salt as a precursor is mixed with ultrapure water to prepare an aqueous cerium solution. Cerium salt and ultrapure water can be mixed at a ratio of 2:1 to 4:1, for example. Here, as the cerium salt, at least one of Ce(III) salt and Ce(IV) salt can be used. That is, at least one Ce(III) salt can be mixed with ultrapure water, or at least one Ce(IV) salt can be mixed with ultrapure water, or at least one Ce(III) salt can be mixed with At least one Ce(IV) salt is mixed with ultrapure water. As the Ce(III) salt, cerium chloride, cerium fluoride, cerium sulfate, cerium nitrate, cerium carbonate, cerium perchlorate, cerium bromide, cerium sulfide, cerium iodide, cerium oxalate, cerium acetate, etc. can be mixed, as Ce(IV) salt can be mixed with cerium sulfate, cerium ammonium nitrate, cerium hydroxide, etc. Among them,...

Embodiment 1

[0074] (Synthesis of precursor particles composed of wet ceria)

[0075] 1000g of cerium (III) nitrate hexahydrate (Ce(NO 3 ) 3 ·6H 2 O) It was dissolved in 250 g of pure water, and 100 g of nitric acid was mixed with the resulting solution to obtain a cerium (III) solution. Next, 1 g of diammonium cerium nitrate ((NH 4 ) 2 Ce(NO 3 ) 3 ) was dissolved in 500 g of pure water to obtain a cerium (IV) solution. Next, the cerium (III) solution is mixed with the cerium (IV) solution to obtain a cerium mixed solution.

[0076] Under a nitrogen atmosphere, 4000 g of pure water was dripped into the reaction container, and then 1000 g of ammonia water was added dropwise to the reaction container, followed by stirring to obtain an alkaline solution.

[0077] Next, the cerium mixed solution was added dropwise to the reaction container, stirred, and heated to 80° C. under a nitrogen atmosphere. Heat treatment was performed for 8 hours to obtain a mixed solution containing wet ceri...

Embodiment 2

[0089] An abrasive was prepared in the same procedure as in Example 1 except that the content ratio (molar ratio) of cerium / lanthanum in the composite oxide particles was set to 50 / 50 (mol %)=1.0. The pH of the obtained abrasive was 6.3, and the average particle diameter of the abrasive particles measured by an electron microscope was 70 nm, the average particle diameter of the matrix particles was 60 nm, and the average particle diameter of the composite oxide particles was 10 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com