An electronic circuit for a high-precision closed-loop Hall current sensor

A Hall current and electronic circuit technology, applied in the direction of measuring current/voltage, voltage/current isolation, instruments, etc., can solve the problem of affecting the current linear measurement range and anti-saturation ability of the current sensor, and the output voltage of the current sensor cannot reach rail-to-rail Rail, affecting the sensor current measurement accuracy and other issues, to achieve the effect of low manufacturing cost, high production efficiency, and wide operating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

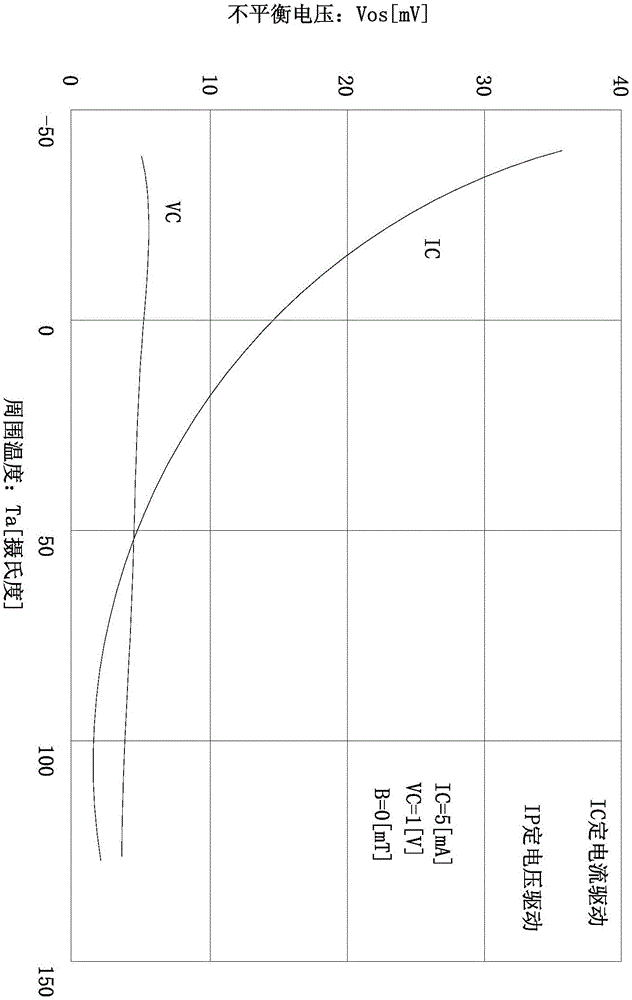

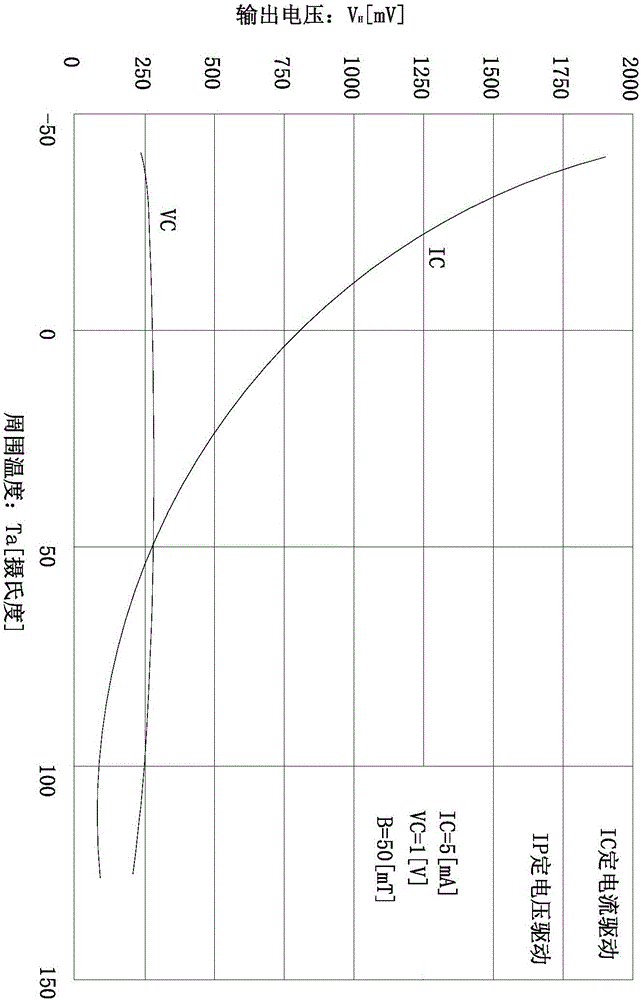

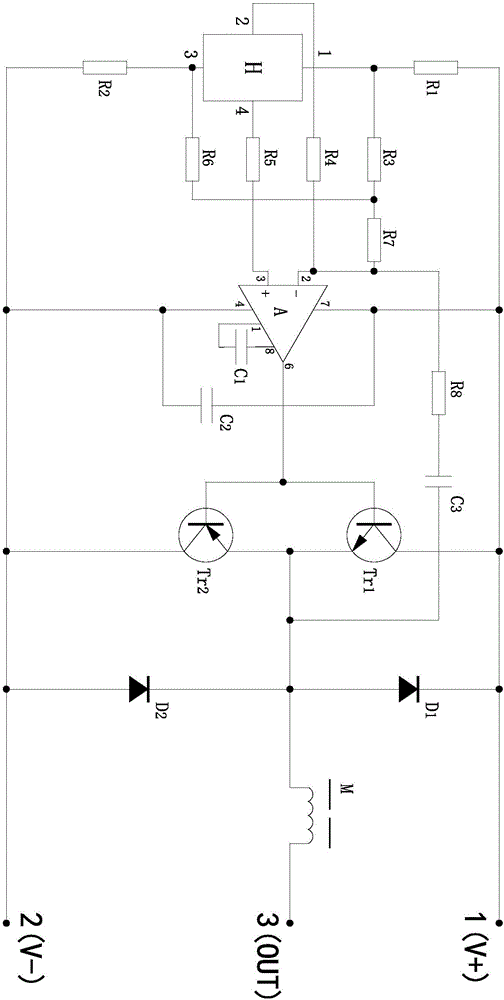

[0028] This embodiment is an electronic circuit for a high-precision closed-loop Hall current sensor, and the block diagram of the electronic circuit of a full PCB-mounted voltage output closed-loop Hall current sensor is as follows Figure 5 , take the current signal from the power supply terminal of the operational amplifier BA4580 and statically bias the output transistor, the output terminal of the operational amplifier directly drives the voltage-controlled load resistor, uses constant voltage work for the Hall element, and performs I / V conversion on the secondary output current, Transformed into the corresponding voltage output, the specific circuit such as Figure 8 In the figure, the constant voltage bias voltage Vz of the Hall element adopts AZ432-1.25V; the power supply terminal of the operational amplifier takes the current signal and statically biases the output triode, and the diodes D1 and D2 adopt the series Schottky diode BAT54S, VD0.58V and 2mA<Ic<10mA, R12=R13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com