Material-filled cylinder for water in-situ purification and construction method thereof

A packing cylinder and in-situ technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. The air bubbles are lost too fast, the efficiency of aeration mass transfer is low, and the effect of adding bacteria agent is not long-lasting, so as to achieve the effect of improving aeration utilization efficiency, prolonging residence time and high purification capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

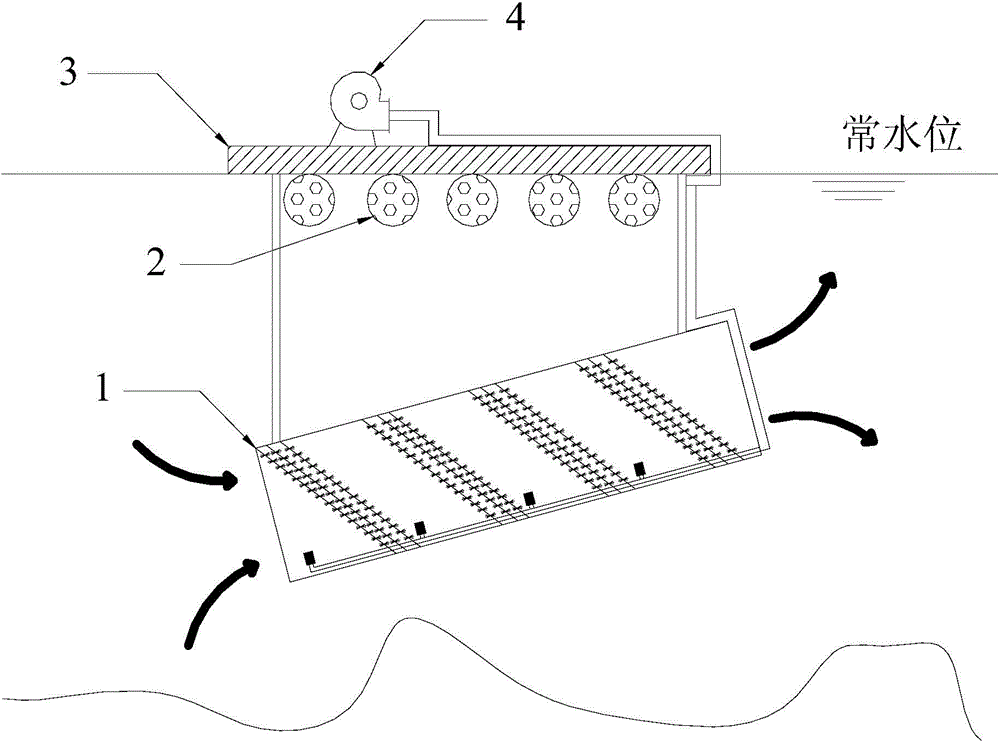

[0047] Depend on figure 1 , figure 2 , image 3 , Figure 4 Composition, application method according to figure 1 shown. For most of the water bodies that need to be repaired in our country, the water depth is relatively shallow, so it is recommended to use rigid connections (such as metal pipes or steel bars), and the surface platform should be supported by floating bodies. Proceed as follows:

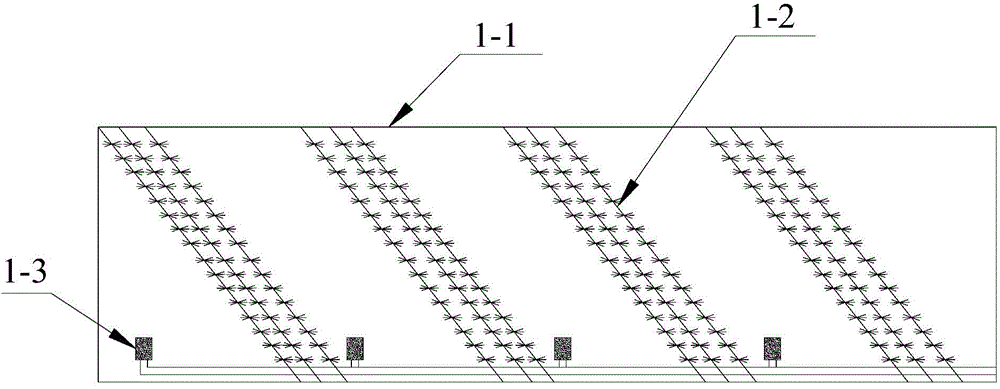

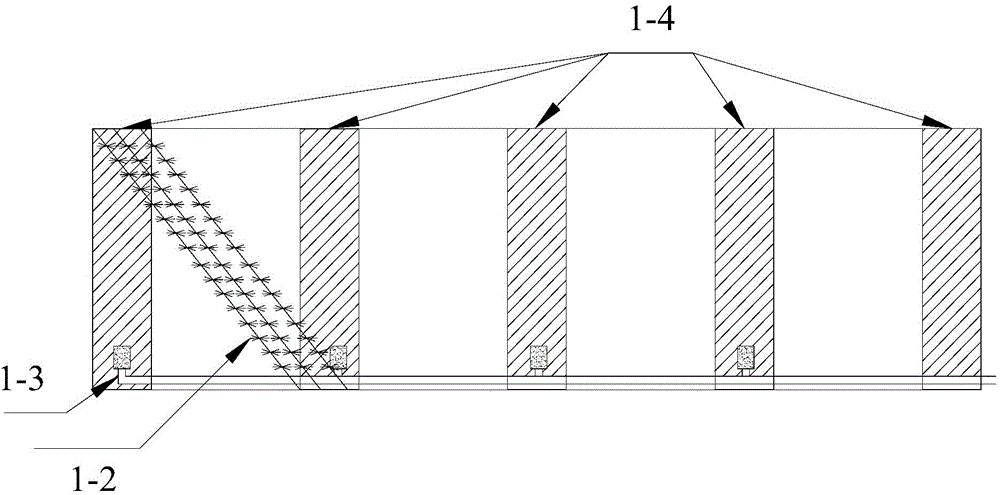

[0048] (1) Build a frame structure. on the shore follow image 3 , Figure 4 Assemble the purge packing cartridge as shown. The cross-section is square, so a metal strip with a certain width (such as 20-40cm wide) can be bent into a square or rectangle (the length and width can be set between 50-200cm) as the rib support structure of the purification cylinder (Figure 1-4 ), and then use tough metal pipes (or angle steel) or bamboo as the keel support and fixed structure at the four vertices of the rectangle (Figure 1-5). 0.8 to 1.8 times) are connected in series and fixed ...

Embodiment 2

[0054] Compared with Example 1, the difference is that the used purification cylinder is assembled in a cylindrical structure, and the material is metal plate or plastic pipe. Here's how to build it:

[0055] (1) adopt the mode similar to embodiment 1 to construct keel-rib frame type structure, by figure 1 , figure 2 , image 3 , Figure 5 Composition, just cross-section is circular, can choose fixed keel to be 3 or 4, and rib material selects metal plate rolling or selects the plastic pipe material of suitable pipe diameter to cut off the appropriate width directly as rib frame, other steps are the same as embodiment 1.

[0056] (2) by figure 1 , figure 2 and Figure 6 The difference in composition and method is that a whole cylindrical pipe is directly used, so there is no need for keels and covering films, and the filler and aeration system are directly drilled on the plastic pipe. Other suspensions and water surface platforms (including blower) are the same as in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com