Photocatalytic coating

A photocatalytic and coating technology, which is applied in the application fields of roofing pellets and building materials, can solve the problems of reducing photoactivity and affecting the color of coated pellets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0024] The operation of the present invention will be further described with reference to the following detailed examples. These examples are provided to further illustrate various specific and preferred embodiments and techniques. However, it should be understood that various modifications and changes can be made without departing from the scope of the present invention.

[0025] Photocatalytic activity test

[0026] The pellets were screened with a -16 / +20 mesh, washed 5 times with deionized water, and dried at 240°F (about 116°C) for about 20 minutes. 40 g of dry pellets were placed in a 500 ml crystallization dish. Then place the 500g4x10 -4 M's disodium terephthalate aqueous solution was added to the crystallization dish. The mixture was stirred with a stir bar driven by a magnetic stirrer under the crystallization dish placed in a petri dish under water. The mixture was exposed to an array of 4 equally spaced, 4 ft (1.2 m) long violet light bulbs (Sylvania 350BL40...

example 1-3 and comparative example A

[0030] Working Examples 1-3 and Comparative Examples A and B

[0031] Samples of Working Example 1 were prepared as described below. Add 2.00g TiO to a 250ml container 2 (W2730X, 30% by weight, experimental product from Degussa AG, Dusseldorf, Germany), 31.80g deionized water, 1.44g potassium silicate (potassium silicate Kasil1, 28.91% by weight, containing 2.47% by weight ratio SiO 2 / K 2 O, obtained from PQ Corporation, Valley Forge, PA), and 18.20 g of a 0.5% by weight aqueous solution of orthoboric acid (99% pure, obtained from Sigma-Aldrich, St. Louis, MO), and stirred well. The resulting mixture was then slowly poured onto 1000 g of WA7100 pellets (untreated, from 3M Company, St. Paul, MN) that had been preheated to 210°F (about 99°C) for one hour and being stirred. While pouring, stir the pellets to ensure an even coating. Continue to agitate the pellets for about 2 minutes. The pellets were then heated with a heat gun until they appeared dry and loose. The dri...

example 4-6

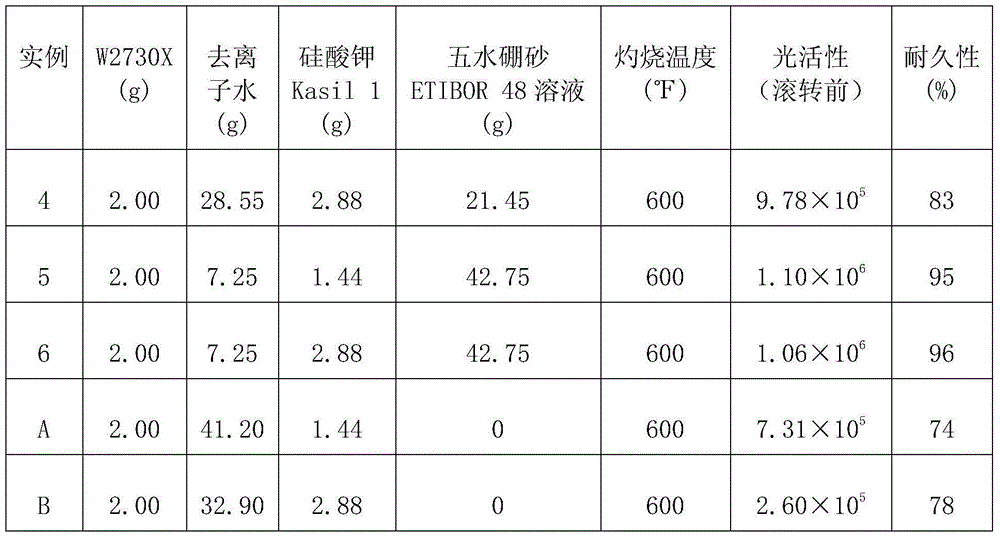

[0037] The samples of Working Examples 4-6 were prepared by the same procedure as that of the sample of Working Example 1 was prepared. The compositions of the photocatalytic coatings of Working Examples 4-6 are listed in Table 2 (for comparison, the compositions of Comparative Examples A and B are also listed). Compared with Working Example 1, sodium tetraborate pentahydrate (borax pentahydrate) was used instead of orthoboric acid. Specifically, a 2% by weight aqueous solution of sodium tetraborate pentahydrate (Borax Pentahydrate ETIBOR 48, available from American Borate Company, Virginia Beach, Virginia) was used.

[0038] The durability of the coated pellets was measured and reported in Table 2 (for comparison, the durability of Comparative Examples A and B are also listed). The results show that the combination of sodium tetraborate pentahydrate (borax pentahydrate) and potassium silicate achieves good durability. Furthermore, the results showed that the use of sodium t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com