Continuous fiber-reinforced titanium-based composite material and preparation method thereof

A titanium-based composite material and continuous fiber technology, which is applied in the field of metal composite materials, can solve the problems of high preparation temperature, insufficient high temperature resistance and creep resistance, insufficient crack growth resistance, etc., and achieves low manufacturing cost and high temperature resistance. , the effect of high specific stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

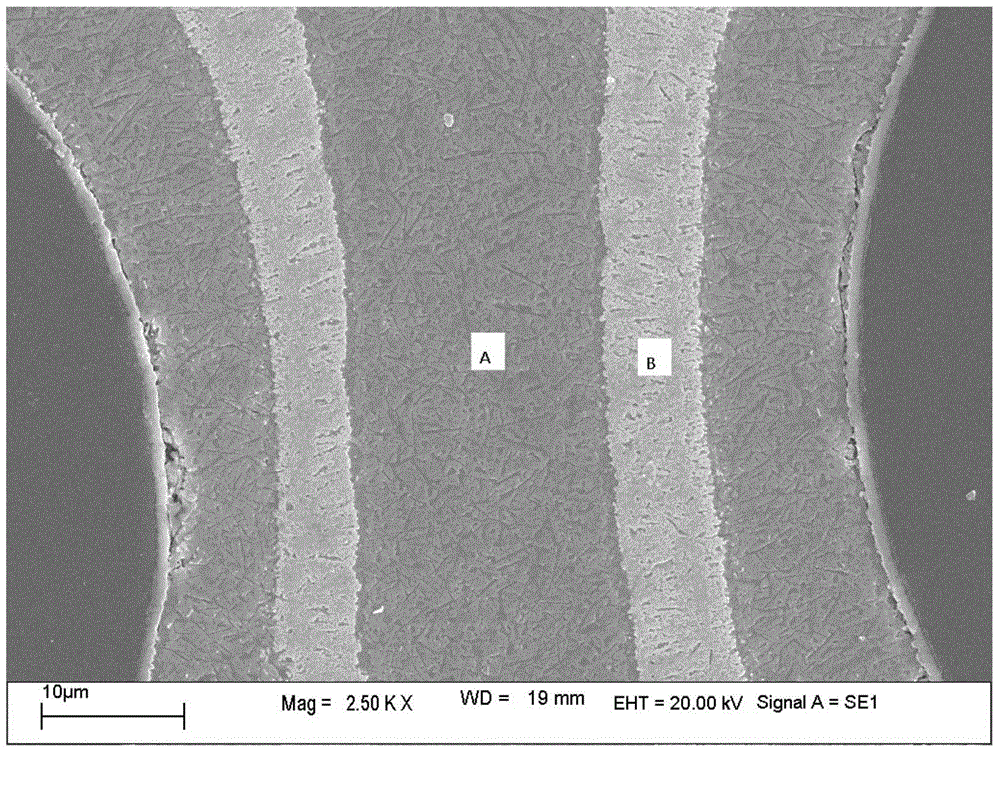

[0048] This embodiment provides a continuous fiber reinforced titanium-based composite material, which is prepared by the following method:

[0049] Preparation of titanium-titanium aluminum composite hybrid precursor wire:

[0050] Put the titanium alloy target in acid solution (by volume ratio, HF:HNO 3 :H 2 (0=5:30:65) was pickled for 30 minutes, and the aluminum alloy target was placed in a 10% NaOH solution for 30 minutes to remove surface impurities. Then, the acid-washed target and SiC fiber were ultrasonically cleaned in acetone for 30 minutes to remove oil stains, and then ultrasonically cleaned in absolute ethanol for 30 minutes to remove acetone to obtain clean SiC fiber, titanium alloy target and Aluminum alloy target.

[0051] Install clean titanium alloy targets and aluminum alloy targets to obtain two pairs of symmetrical planar targets, namely a pair of titanium alloy targets and a pair of aluminum alloy targets;

[0052] Wind the clean SiC fiber on the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com