A method of low-power plasma spraying that greatly improves the vaporization of flying particles

A plasma and large-scale technology, applied in the direction of coating, fusion spraying, metal material coating process, etc., can solve the problems of low production cost, etc., and achieve the effect of increasing temperature, increasing residence time, and increasing heating degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

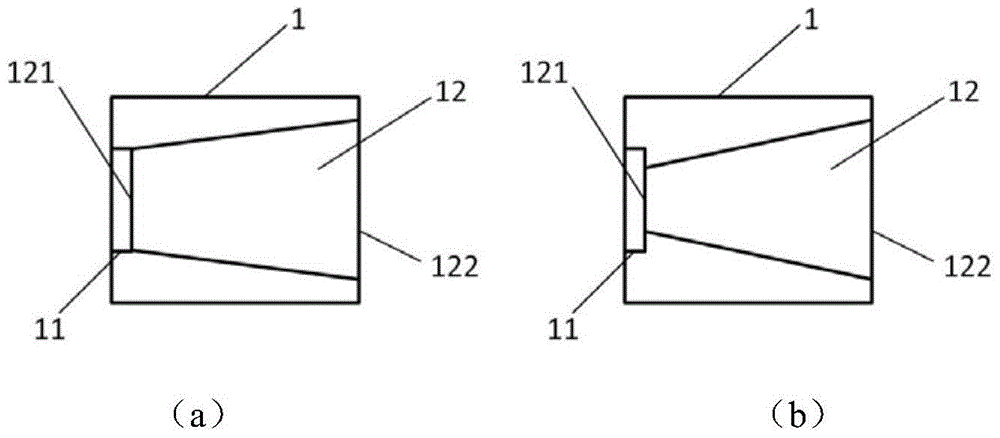

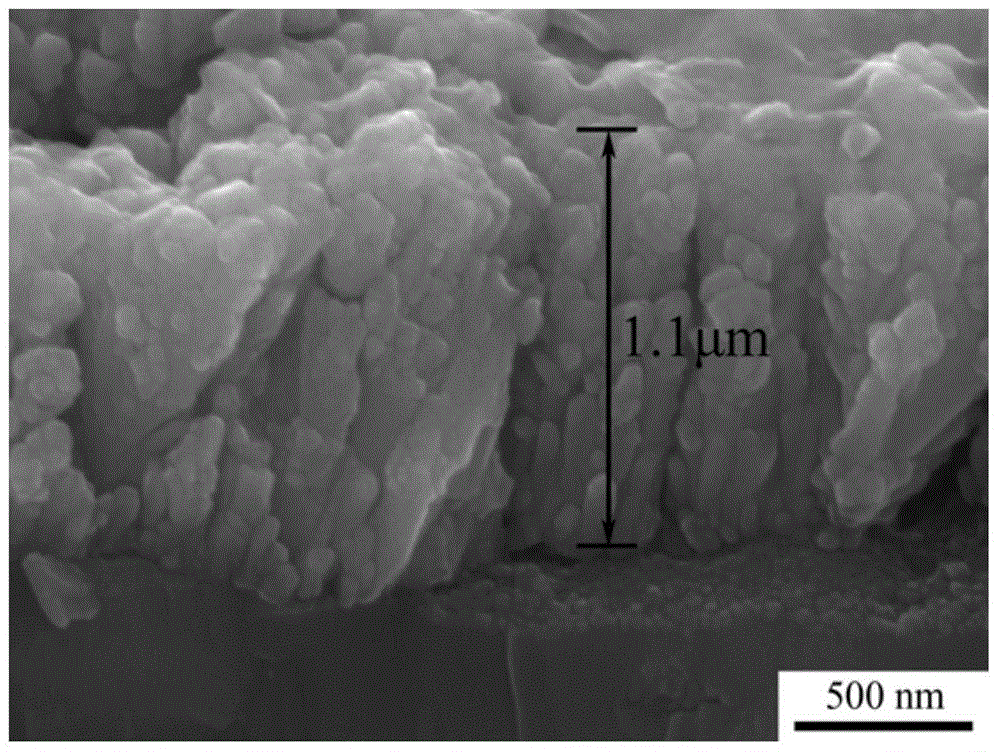

Embodiment 1

[0041] The aluminum oxide tube is used as the substrate, and it is processed into a sample of Φ16×2×250mm (outer diameter×thickness×length). Use acetone and alcohol to ultrasonically clean the sample in turn, use aluminum oxide sandpaper to polish the surface of the sample, and finally use alcohol to clean the surface of the sample; figure 1 (a) the plasma spray gun of bunching cover, under 100Pa ambient pressure, use 7-8wt.% YSZ powder to carry out PS-PVD process, prepare YSZ coating, wherein spraying parameter is spraying rated power 45kW, removes the net of cooling power Power is 25kW, Ar 40L / min, H 2 8L / min, spraying distance 200mm, powder feeding volume 0.2g / min, side deposition method. The cross-sectional structure of the coating (such as Figure 4 shown) appears as a columnar-like structure. The thickness of the coating with a buncher hood is about twice that of the coating without a buncher hood, which proves that the gasification amount of the powder is significan...

Embodiment 2

[0043] With zirconia as the matrix, it is processed into a sample of Φ18×2mm (diameter×thickness). Use acetone and alcohol to ultrasonically clean the sample in turn, use diamond sandpaper to polish the surface of the sample, and finally use alcohol to clean the surface of the sample; figure 1 (b) Beaming hood and plasma spray gun without beaming hood, under 100Pa ambient pressure, use 7-8wt.% YSZ powder to carry out PS-PVD process, prepare YSZ coating, wherein spraying parameters are spraying rated power 60- 80kW, net power excluding cooling power is 32-45kW, Ar 50-70L / min, H 2 10-15L / min, spraying distance 200-660mm, powder feeding amount 0.2g / min, side deposition method. Coating thicknesses deposited with the addition of a beam mask are significantly increased.

Embodiment 3

[0045] The aluminum oxide tube is used as the substrate, and it is processed into a sample of Φ16×2×250mm (outer diameter×thickness×length). Use acetone and alcohol to ultrasonically clean the sample in turn, use aluminum oxide sandpaper to polish the surface of the sample, and finally use alcohol to clean the surface of the sample; figure 1 (a) The plasma spray gun of the buncher cover, under less than 500Pa ambient pressure, use aluminum oxide powder to carry out PS-PVD process, prepare aluminum oxide coating, wherein spraying parameter is spraying rated power 45-80kW, removes the net of cooling power Power 25-45kW, Ar 40-70L / min, H 2 8-15L / min, spraying distance 200-660mm, powder feeding rate 0.2g / min, side deposition method. Preparation of vapor-deposited columnar structure alumina coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com