Planar magnetron sputtering target

A magnetron sputtering and planar technology, which is applied in sputtering plating, ion implantation plating, metal material coating technology, etc., can solve the problem of low utilization rate of magnetron sputtering targets, and avoid magnetic short circuit phenomenon , Reasonable layout and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

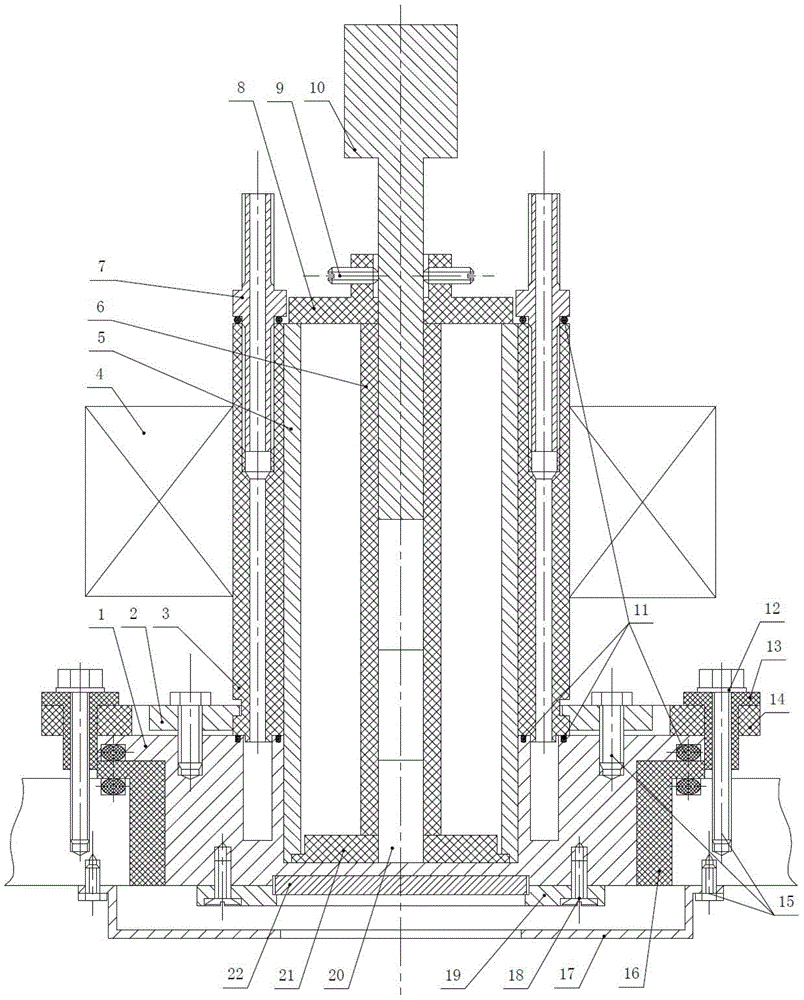

[0038] A planar magnetron sputtering target is characterized in that it is composed of a flange 1, a pressure sleeve 2, a water tube 3, an excitation coil 4, an electrical pure iron sleeve 5, an insulating sleeve 6, a nozzle 7, a pressure plate 8, Set screw 9, electrical pure iron pressure rod 10, sealing ring 11, washer 12, insulating sleeve 13, pressing ring 14, bolt 15, insulating spacer 16, shielding cover 17, slotted countersunk head screw 18, pressing ring 19 , NdFeB permanent magnet column 20 and positioning bracket 21, wherein the large end of positioning bracket 21 is placed horizontally in the circular deep groove in the center of flange 1; electrician pure iron sleeve 5 and positioning bracket 21 are fixed In the circular deep groove in the center of the flange 1; the NdFeB permanent magnet column 20 is stacked in the insulating sleeve 6, and one end of the NdFeB permanent magnet column 20 is inserted into the through hole in the center of the positioning bracket 21,...

Embodiment 2

[0053] A planar magnetron sputtering target, the structure of which is the same as in Embodiment 1.

[0054] in:

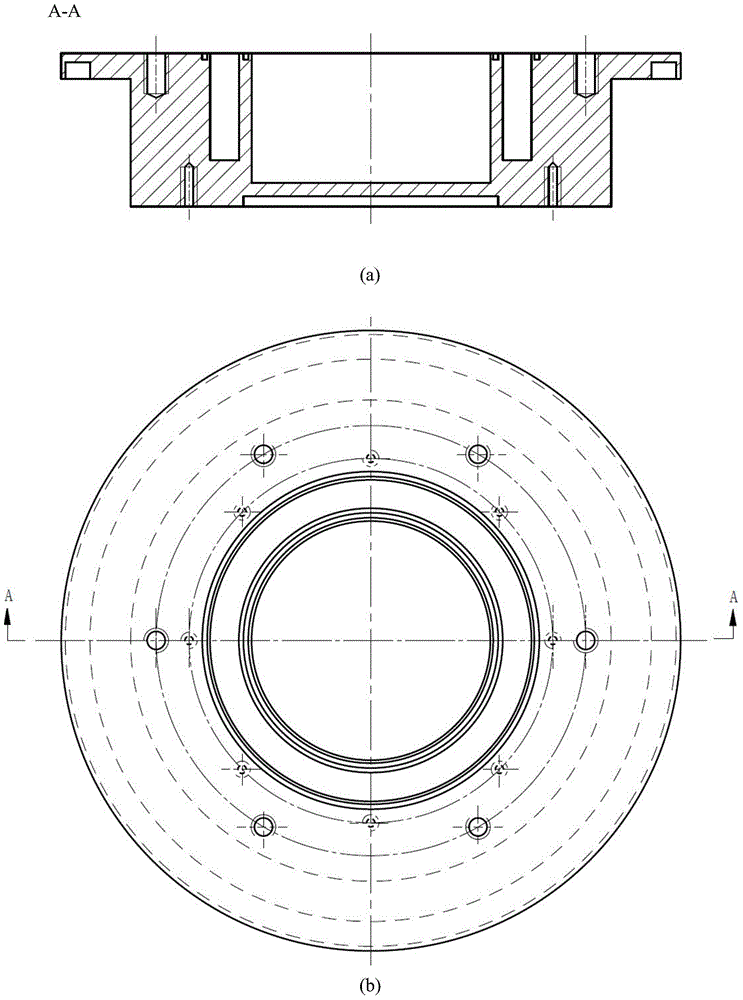

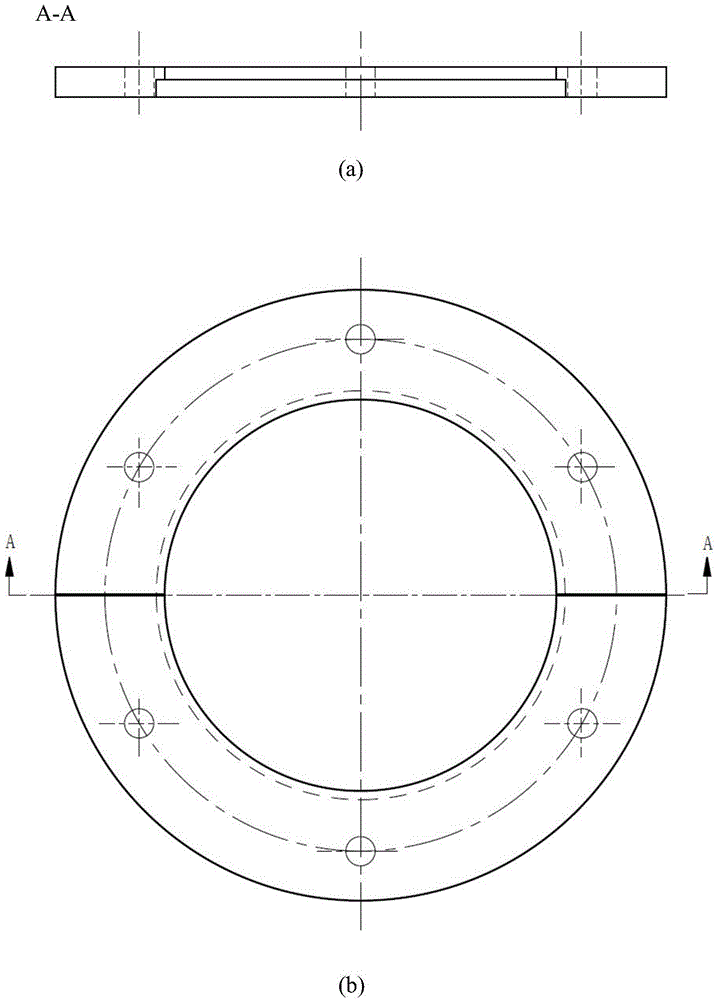

[0055] ①The insulating sleeve and the insulating spacer are processed by polytetrafluoroethylene, and the insulating sleeve and the insulating spacer are both cylindrical with a bottom and two steps. The total height of the insulating sleeve is 21.5mm, the diameter of the central hole is Φ6mm, the outer diameter of the small end cylinder is Φ10mm, and the outer diameter and height of the large end cylinder are Φ20mm and 3.5mm respectively. The total height of the insulating spacer is 35mm, the diameter of the central hole is Φ132mm, the outer diameter of the small end cylinder is Φ150mm, and the outer diameter and height of the large end cylinder are Φ175mm and 5mm respectively.

[0056] ②Phenolic resin is used to process the pressure ring. The pressure ring is ring-shaped. The inner diameter and outer diameter are Φ146mm and Φ205mm respectively, and the height i...

Embodiment 3

[0067] A planar magnetron sputtering target, the structure of which is the same as in Embodiment 1.

[0068] in:

[0069] ①The insulating sleeve and the insulating spacer are processed by polytetrafluoroethylene, and the insulating sleeve and the insulating spacer are both cylindrical with a bottom and two steps. The total height of the insulating sleeve is 21.5mm, the diameter of the central hole is Φ6mm, the outer diameter of the small end cylinder is Φ10mm, and the outer diameter and height of the large end cylinder are Φ20mm and 3.5mm respectively. The total height of the insulating spacer is 35mm, the diameter of the central hole is Φ132mm, the outer diameter of the small end cylinder is Φ150mm, and the outer diameter and height of the large end cylinder are Φ175mm and 5mm respectively.

[0070] ②Phenolic resin is used to process the pressure ring. The pressure ring is ring-shaped. The inner diameter and outer diameter are Φ146mm and Φ205mm respectively, and the height i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com