Impeller-directly-driven wind-driven generator

A technology for wind turbines and impellers, which is applied to wind turbine components, wind turbines, wind turbine combinations, etc., can solve the problem that the electric power and frequency are difficult to maintain stable, the technical difficulty of large-megawatt converters is difficult, and the wind turbines are restricted. Development and other issues, to achieve the effect of optimizing product function adjustment, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

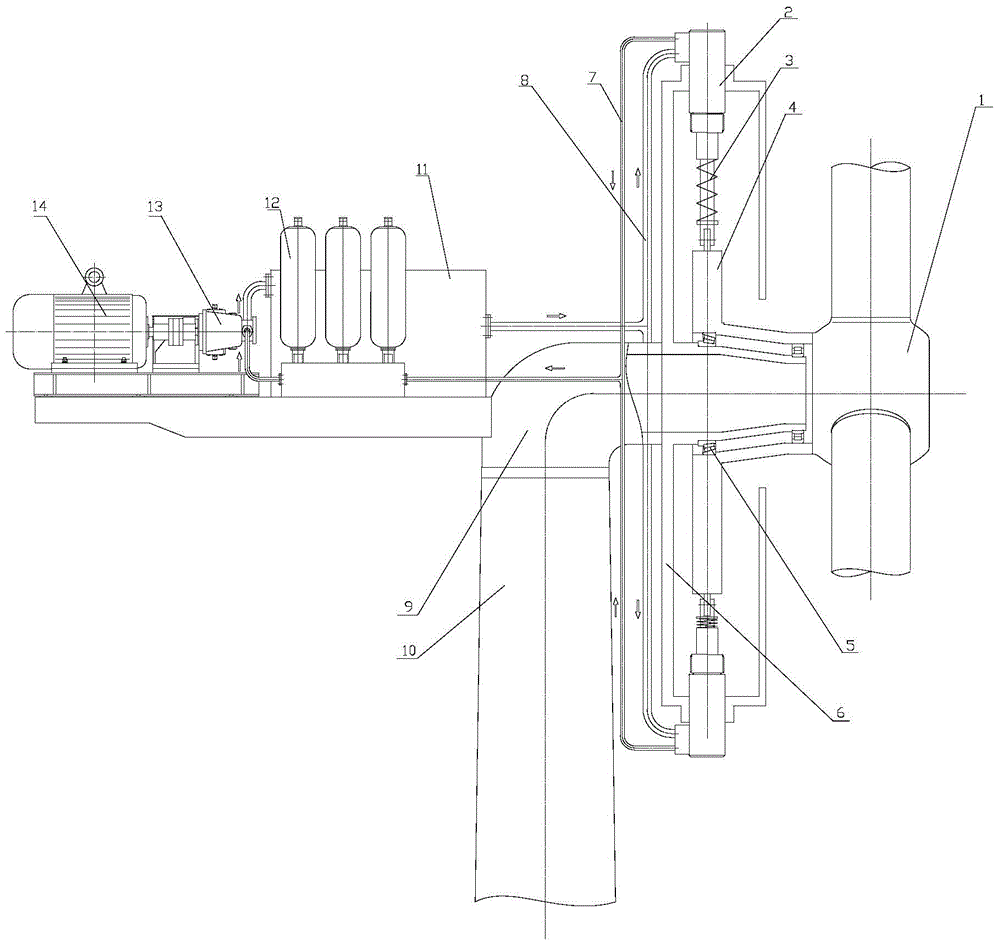

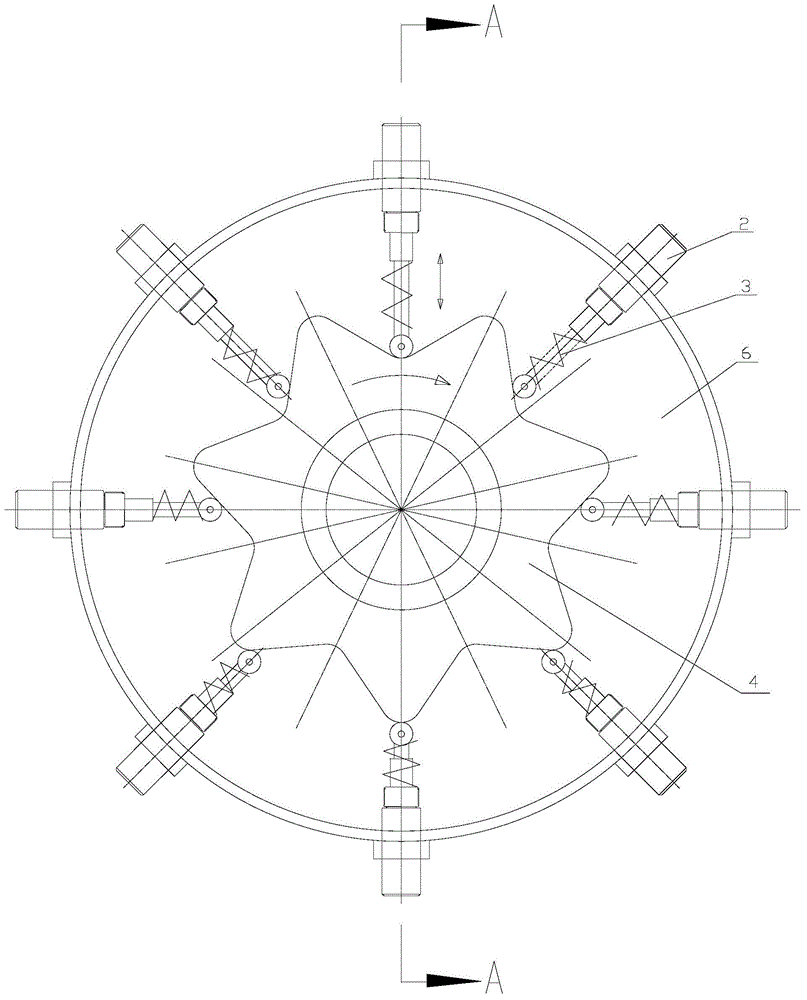

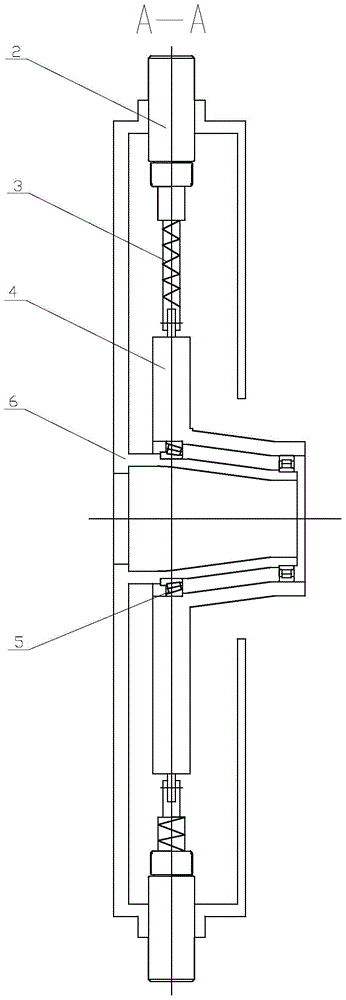

[0018] The present invention will be further described below in conjunction with accompanying drawing. During the work of the present invention, the wind-driven blade drives the impeller 1 to rotate, and the impeller 1 drives the cam turntable 4 to rotate. There are 8 hydraulic cylinders 2 evenly distributed around the cam turntable 4. The cylinder body is installed on the bracket 6, and the bracket 6 is fixed on the main frame 9. The plunger of the hydraulic cylinder 2 is in contact with the cam turntable 4 through the roller installed on the plunger. At the same time, a spring 3 is installed on the plunger to ensure that the roller and the cam turntable 4 are always attached. When the cam turntable 4 rotates, the cam turntable 4 drives the piston of the hydraulic cylinder 2 to reciprocate, thereby realizing the process of converting mechanical energy into hydraulic energy. . The high-pressure oil generated by the hydraulic cylinder 2 is transmitted to the high-speed hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com