Air duct protection plate for soft and hard co-extrusion sealing and production method thereof

A technology of soft and hard co-extrusion and air duct guards, which is applied to household refrigeration devices, applications, household appliances, etc., can solve the problems of affecting sealing performance and increasing costs, so as to prolong the service life, facilitate assembly, and improve structural stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

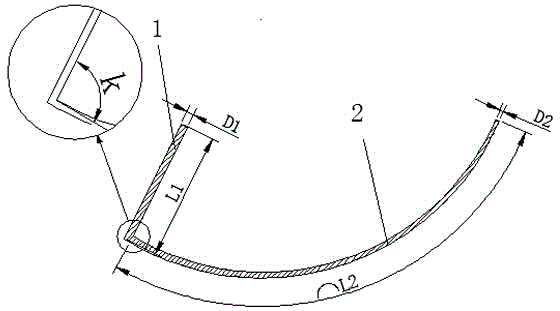

[0009] Embodiment of the present invention: the production of soft and hard co-extruded air duct guard plate for sealing, the hard PVC with Shore hardness of 75 degrees and Shore hardness of 110 degrees is passed through the main extruder and the co-extrusion of diameter R2 respectively Extruded from the head of the machine, the co-extrusion mold and traction rollers are pulled to form the extrusion die; finally cooled and shaped to obtain the profiled material. The structure of the profile is as figure 1 As shown, it includes a hard structural part 1 and a soft functional part 2, the hard structural part 1 is a strip structure; the soft functional part 2 is an arc surface structure; one side of the hard structural part 1 and the soft functional part 2 One side is connected as a whole in the co-extrusion process; the total width of the hard structural part and the soft functional part is L, the width of the hard structural part is L1, the width of the soft functional part is L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com