Acceleration sensor

A technology of acceleration sensor and sensor housing, which is applied in the direction of acceleration measurement, instrument, and measuring device using inertial force, can solve the problems of complex secondary processing circuit, simple protection, high cost, etc., and achieve simple production, simple amplification circuit, The effect of analog signal stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the drawings and embodiments.

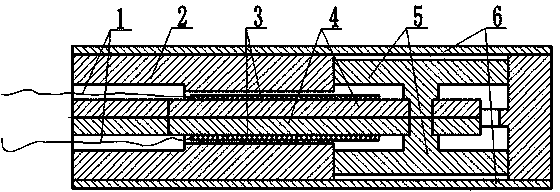

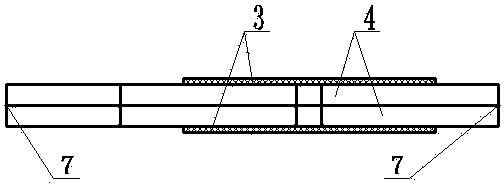

[0015] Such as Figure 1-2 As shown, an acceleration sensor includes a lead wire 1, a sensor housing 2, a metal strain gauge 3, a composite elastic beam 4, a mass 5, and a cover plate 6. The sensor housing 2 is provided with a composite elastic beam 4, so The sensor housing 2 is made of 304 stainless steel, and both sides are provided with ear holes for fixing. The composite elastic beam 4 is made of 17-4PH stainless steel, the sensor housing 2 is equipped with a cover plate 6, the upper and lower surfaces of the composite elastic beam 4 are each pasted with metal strain gauges 3, and the metal strain gauges 3 are provided with lead wires. 1. The lead wire 1 is led out from the side of the sensor housing 2. A fixing hole is reserved at the front of the composite elastic beam 4, and a mass 5 is installed up and down in the fixing hole. The mass 5 is symmetrical with resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com