Weak-interface and low-strength rock sample making apparatus and sample making method thereof

A technology of rock sample and preparation device, which is applied in the preparation of test samples and other directions, can solve the problems of high breakage rate and difficult preparation of low-strength rock samples, and achieves low surface breakage rate, small damage, and improved flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

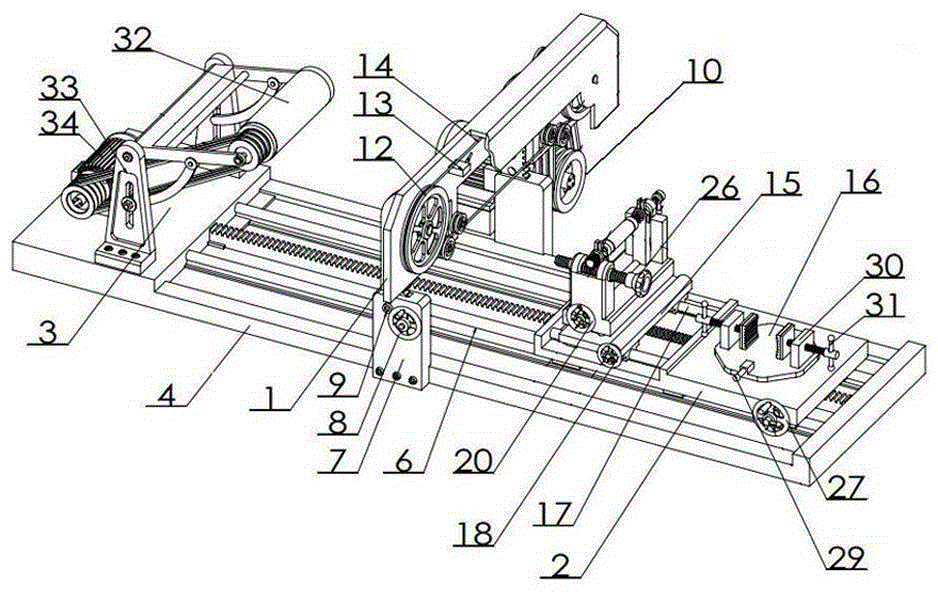

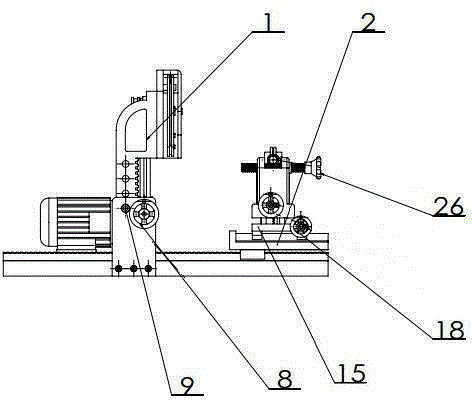

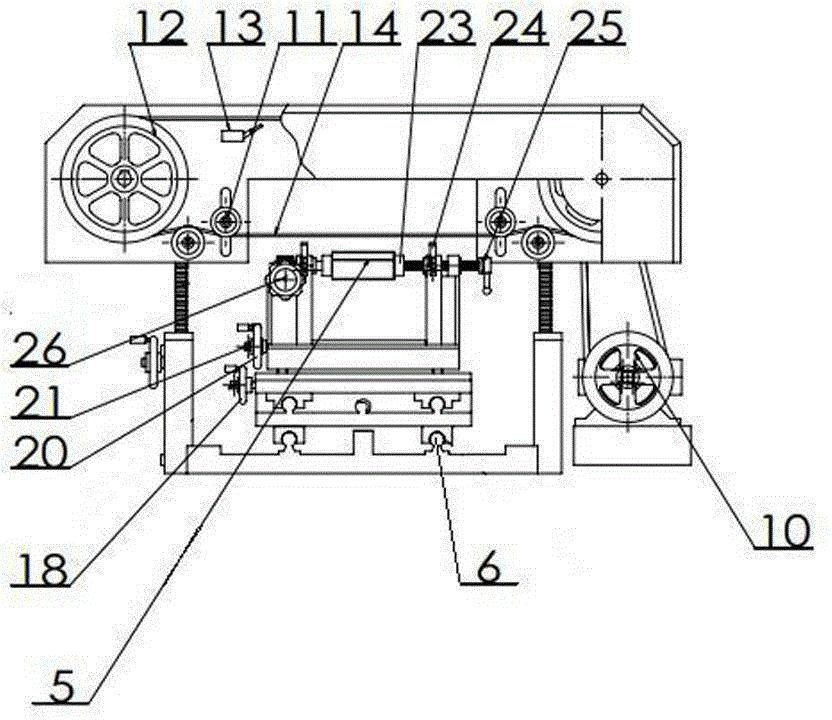

[0049] Such as figure 1 As shown, the low-strength rock sample preparation device with a weak interface is composed of a diamond wire saw machine 1, a workbench 2, and a grinder 3 arranged on a base 4. Refer to Figure 5 , a cutting table 15 and a clamping turntable 16 are set on the workbench 2, and the diamond wire saw machine 1 spans the base 4 through the steel brackets 7 on both sides. The rail 6 passes under the diamond wire saw machine 1, and the workbench 2 can move horizontally on the translation slide rail 6. The workbench 2 can move the cutting table 15 or the clamping turntable 16 to the diamond wire 14 of the diamond wire saw machine respectively. Below, the workbench 2 can also move the cutting table 15 below the grinding cylinder 32 of the grinding machine 3 . The workbench 2 is provided with a propulsion handwheel 27, and the workbench 2 is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com