Hydrate formation monitoring method and system based on optics

A hydrate generation and monitoring system technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of high cost, large drift, low sensitivity, etc., to improve the measurement accuracy, reduce the volume of the gas chamber, and increase the absorption optical path Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

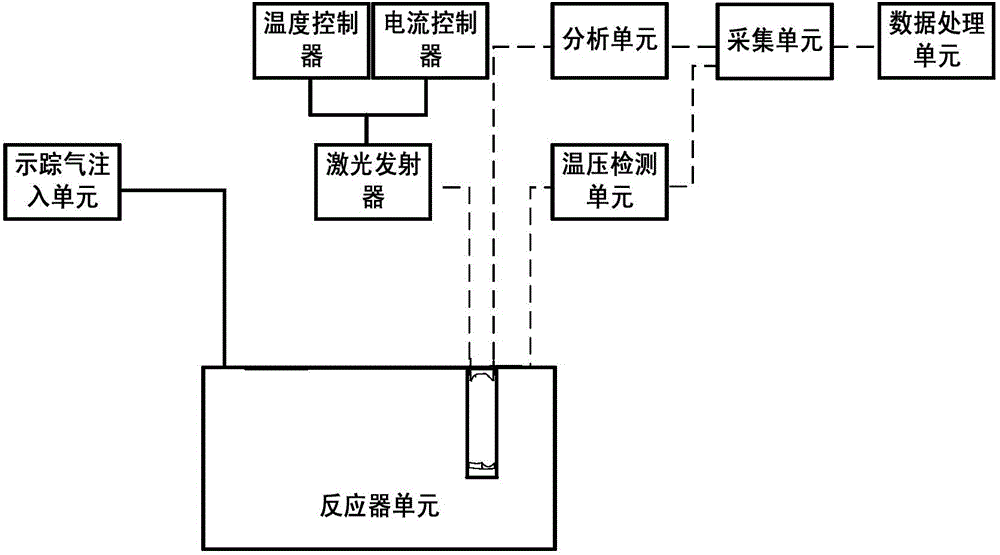

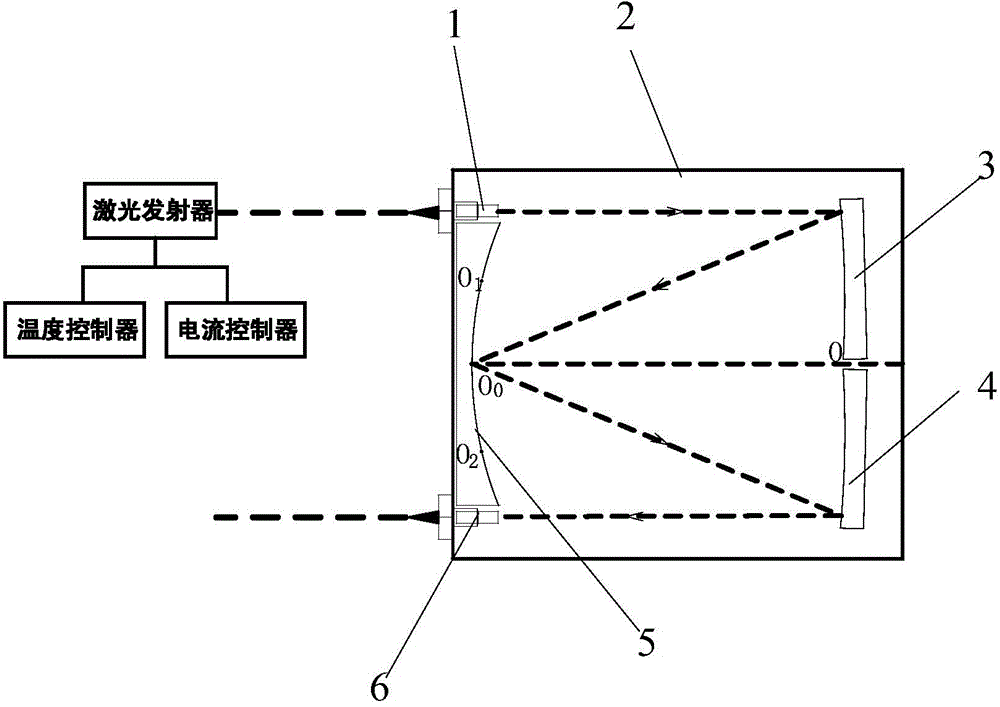

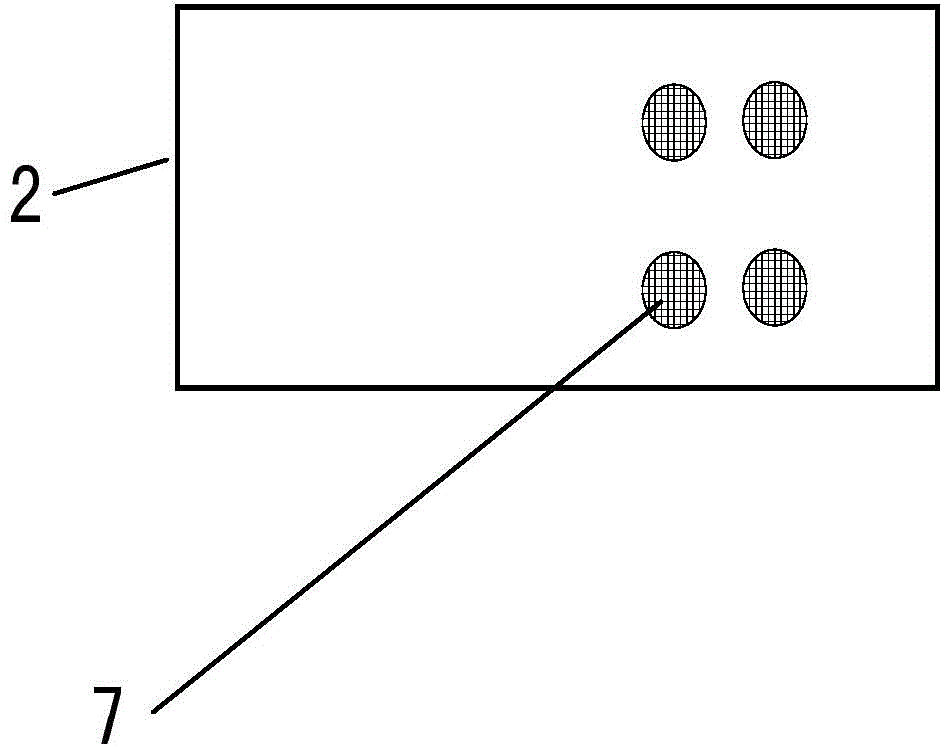

[0038] Such as figure 1 and figure 2As shown, an optical-based hydrate formation monitoring system includes a tracer gas injection unit that injects tracer gas into the reactor unit, and is used to input and output laser light into the reactor unit to track the tracer gas in the reactor unit. Hydrate formation monitoring unit for gas concentration changes, analysis unit for detecting the intensity of laser light emitted by the hydrate formation monitoring unit, temperature and pressure detection unit for detecting temperature and pressure in the reactor unit, temperature and pressure detection unit for collecting and analyzing unit data collection unit, and a data processing unit for processing the data collected by the collection unit so as to judge whether there is hydrate formation therein, the hydrate formation monitoring unit includes a laser emitter, a gas permeable gas set in the reactor unit Chamber 2, the gas chamber 2 includes a White cell for the gas to absorb las...

Embodiment 2

[0046] A method for monitoring hydrate formation based on the system, comprising the steps of:

[0047] Inject tracer gas into the reactor unit through the tracer gas injection unit;

[0048] The laser emitter emits a laser with a certain frequency and enters the air chamber 2 through the incident optical fiber and the first self-focusing lens 1, and is reflected by each concave lens in the air chamber 2. After being coupled by the second self-focusing lens 6, it is emitted through the outgoing optical fiber;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com