Enameled wire coating removal device

An enamelled wire varnish and positioning device technology, which is applied to lines/collector parts, equipment for dismantling/armored cables, electrical components, etc., can solve problems such as unfavorable batch operations, large environmental damage, and poor paint removal accuracy, and achieve High paint removal precision, easy to use, high scraping precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

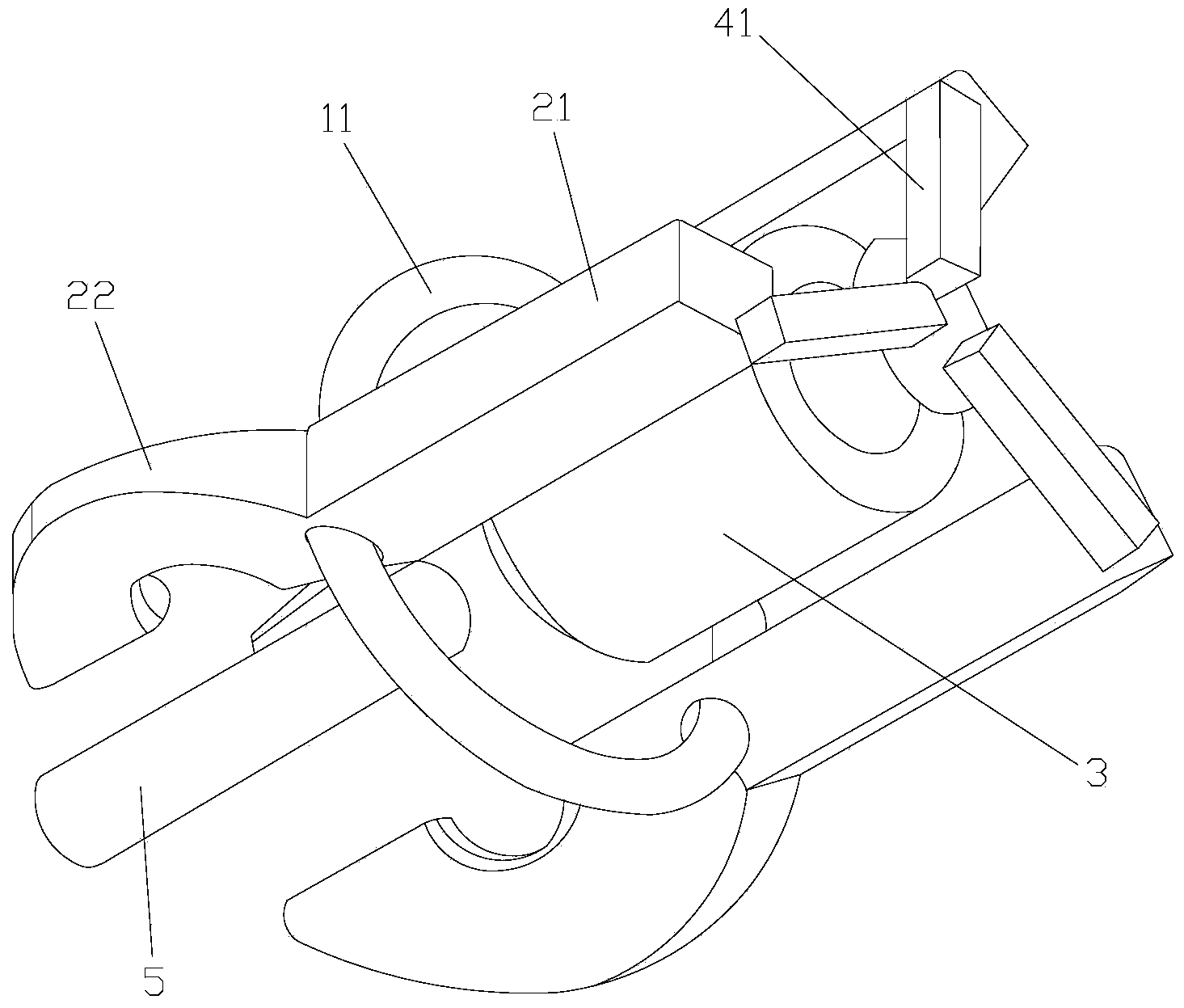

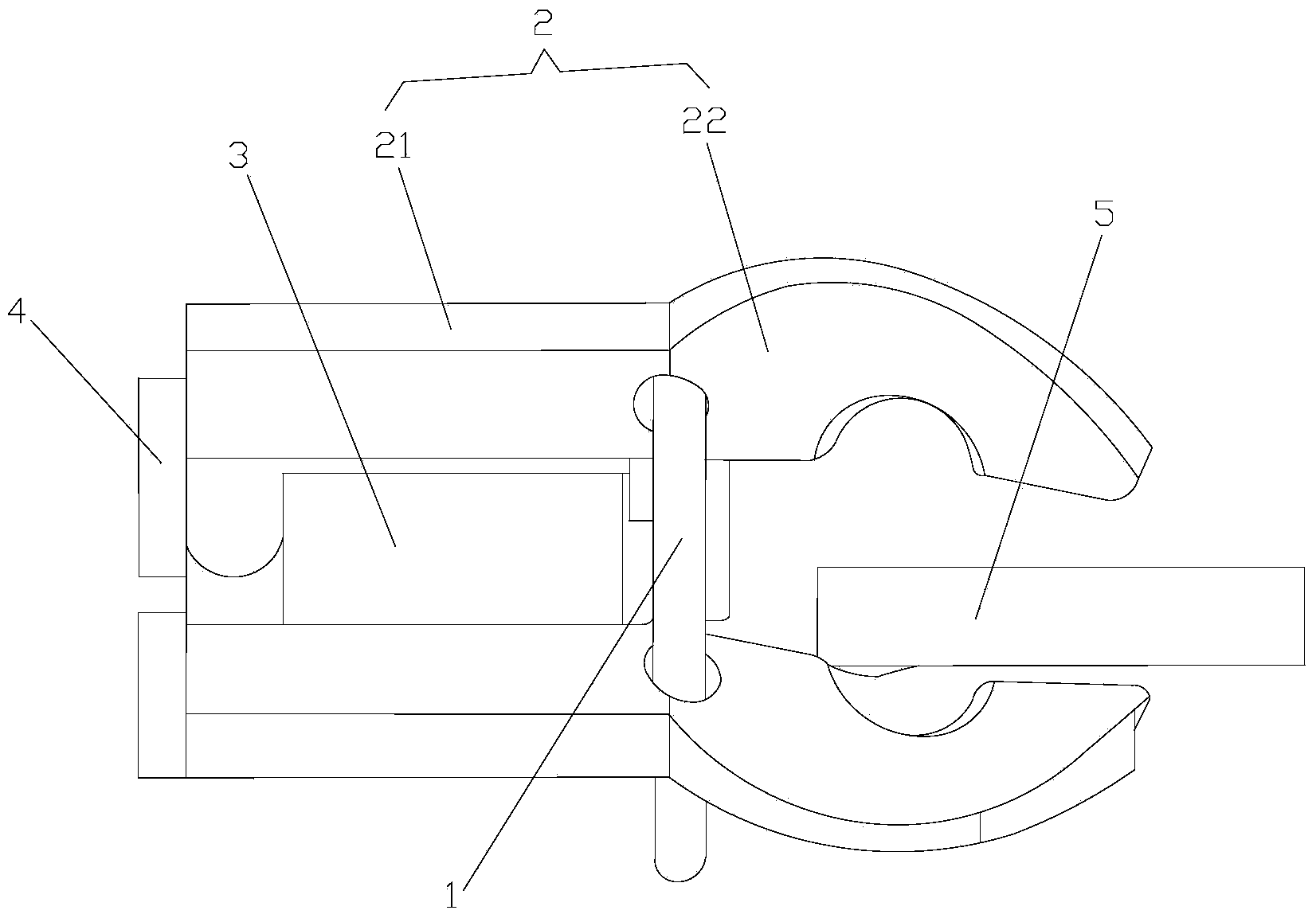

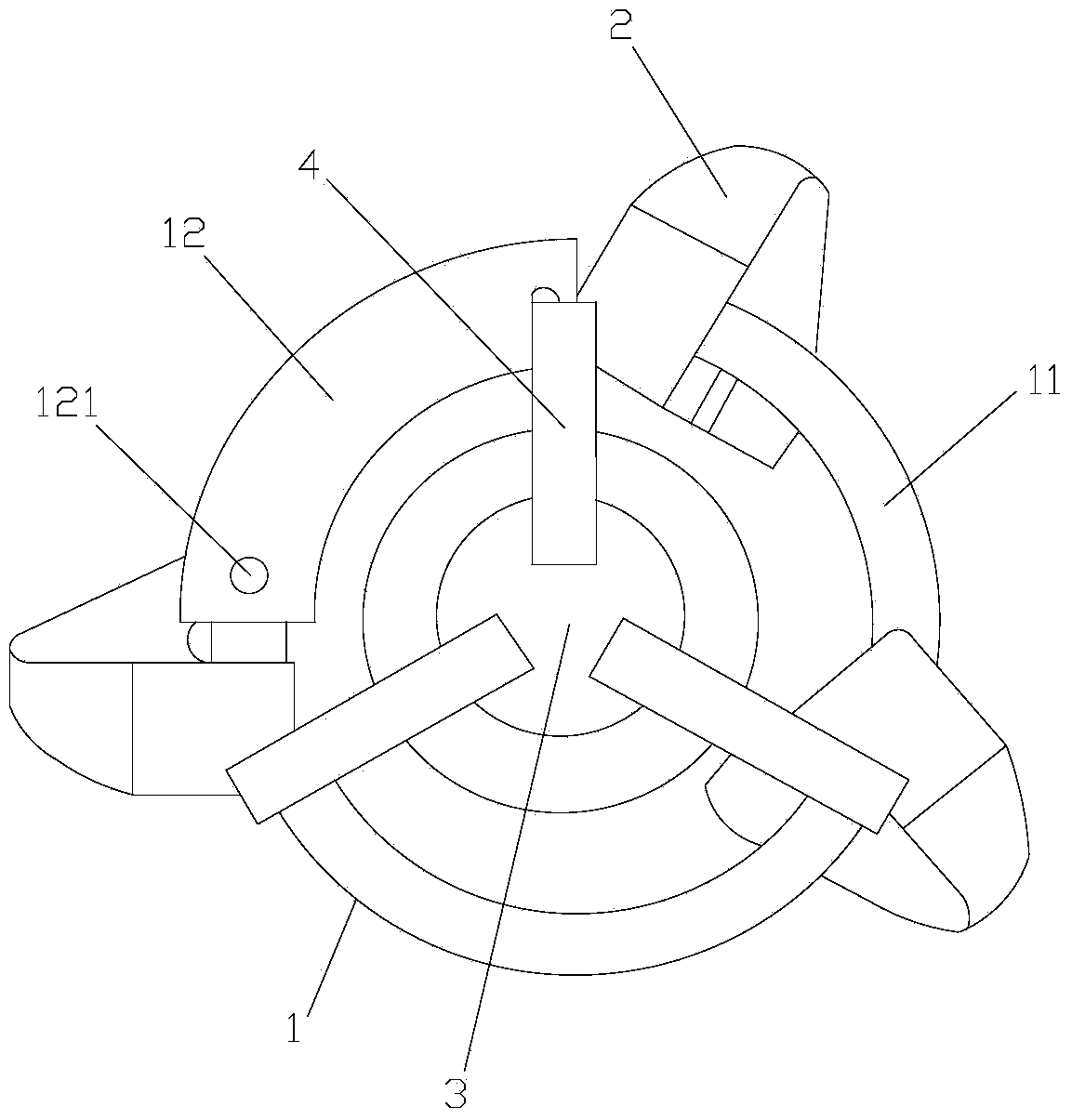

[0024] Such as Figures 1 to 8 As shown, the enameled wire paint skin removal device of the present invention includes a positioning device 1 , a cutter head device 2 , a motor device 3 and a lever device 4 .

[0025] The positioning device 1 has a ring-shaped structure as a whole, which includes a positioning ring 11 and a positioning ring sleeve 12; wherein, the positioning ring 11 is an integral ring structure; 11, a pair of positioning fasteners 121 are arranged symmetrically at both ends of the positioning ring 12. In this embodiment, the positioning fastener 121 is a positioning locking screw, and its function is to adjust the size of the cutter head and lock it.

[0026] The cutter head device 2 is cast from cemented carbide steel, and it is three matched on the positioning ring 11 of the positioning device 1; the three cutter head devices 2 are evenly distributed on the positioning ring 11 according to 120 degrees , completely wraps the enamelled round copper wire, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com