Driving system of high-voltage permanent magnet synchronous motor

A permanent magnet synchronous motor and drive system technology, applied in the direction of single motor speed/torque control, emergency protection circuit device for limiting overcurrent/overvoltage, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

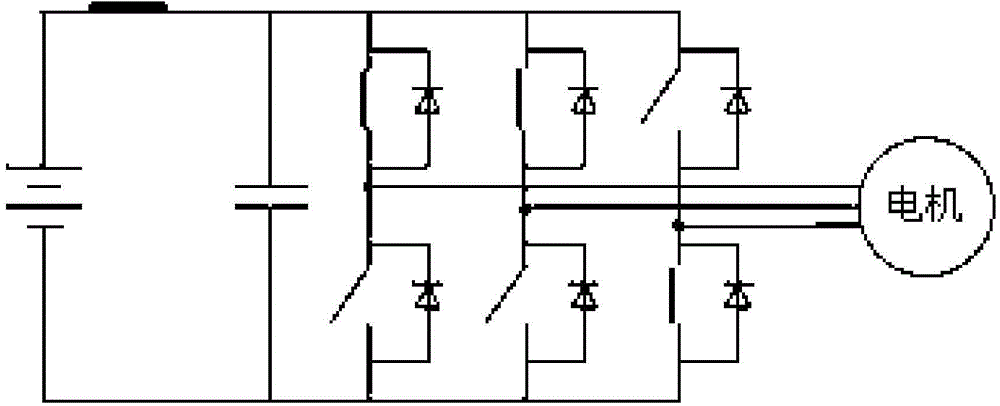

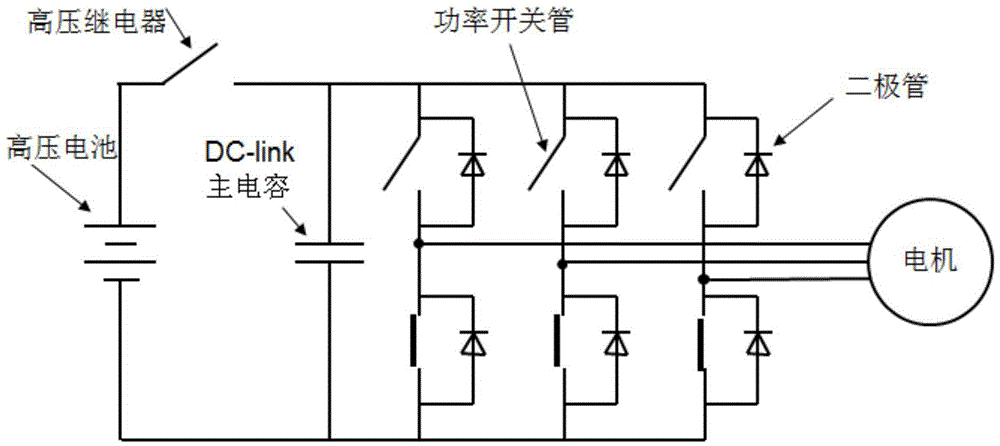

[0038] High-voltage permanent magnet synchronous motor drive system, including high-voltage relay (Main Relay), main capacitor, three-phase bridge AC inverter circuit, motor controller, active clamp circuit;

[0039] The main capacitor is connected in parallel with the three bridge arms of the three-phase bridge AC inverter circuit and is connected in series with the high-voltage relay at both ends of the high-voltage battery;

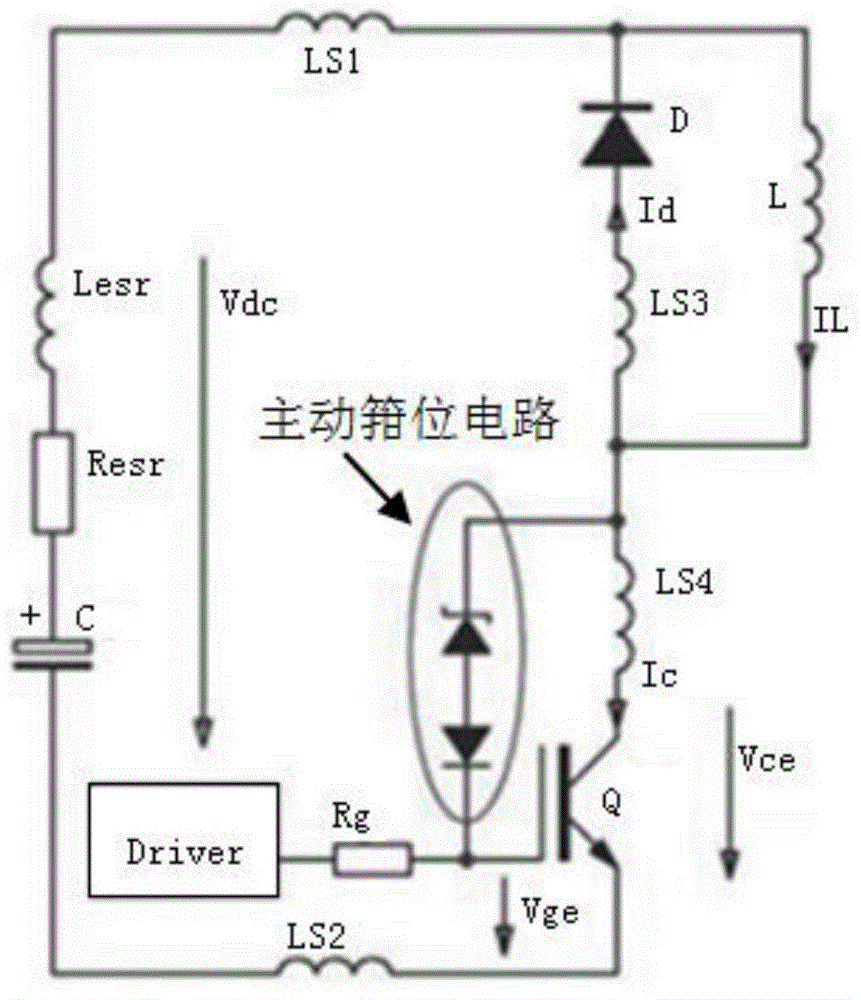

[0040] The power tube of the three-phase bridge AC inverter circuit adopts IGBT (insulated gate bipolar transistor), the gate (G pole) and the collector (C pole) of the three IGBTs of the upper bridge arm of the three bridge arms An active clamp circuit is set between;

[0041] The motor controller, when the high-voltage relay (Main Relay) is cut off, enters the fast active discharge mode;

[0042]The motor controller, in the fast active discharge mode, if the voltage at both ends of the main capacitor exceeds the clamping threshold, it immediately co...

Embodiment 2

[0049] Based on the high-voltage permanent magnet synchronous motor drive system of the first embodiment, when the drive system fails (for example, the permanent magnet synchronous motor drive system has an overvoltage fault, an overtemperature fault, a sensor signal loss fault, etc.), the motor controller immediately controls the The three IGBTs of the lower bridge arm of the three bridge arms of the three-phase bridge AC inverter circuit are all turned on, the three IGBTs of the upper bridge arm are all turned off, and the three-tube short circuit (ASC, Active short circuit) mode is entered, and at the same time Send a request to cut off the high voltage relay (Main relay) to the vehicle controller (VCU);

[0050] The vehicle controller (VCU), after receiving the request to cut off the high-voltage relay (Main relay), controls the high-voltage relay to cut off, and outputs a high-voltage relay cut-off signal to the motor controller;

[0051] The motor controller enters the f...

Embodiment 3

[0055] Based on the high-voltage permanent magnet synchronous motor drive system of the first embodiment, the motor controller includes a microcontroller and a complex programmable logic device (CPLD);

[0056] After the motor controller enters the fast active discharge mode, the working process is as follows:

[0057] (1) The complex programmable logic device logic triggers fault interrupt;

[0058] (2) The microcontroller identifies the fault interruption, and sends a six-tube freewheeling command to control all six IGBTs of the three bridge arms of the three-phase bridge AC inverter circuit to be disconnected, and counts in n milliseconds After that, send the command to release the six-tube full break (Freewheeling) to exit this state;

[0059] (3) The complex programmable logic device (CPLD) recognizes the release six-tube freewheeling command, and controls all the three IGBTs of the lower bridge arm of the three bridge arms of the three-phase bridge AC inverter circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com