Double-headed grinding device and method for double-headed grinding of workpieces

A technology for double-sided grinding and workpiece grinding is applied in the direction of grinding workpiece supports, machine tools suitable for grinding workpiece planes, grinding devices, etc. Achieving the effect of high-precision nanotopography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 4

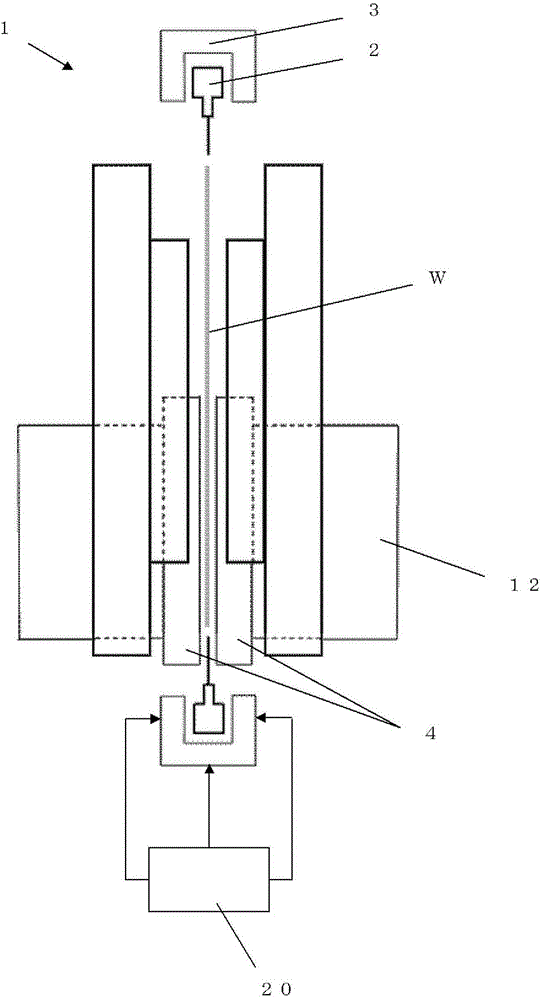

[0070] use figure 1 The double-sided grinding apparatus 1 of the present invention shown in , performs double-sided grinding of a silicon wafer with a diameter of 300 mm. As a grindstone, an SD#3000 grindstone (a vitrified grindstone manufactured by A.L.M.T.) made of a vitrified sintered material was used. The amount of grinding was 40 μm. Water was used as the fluid for supporting the ring retainer.

[0071] The supply pressure of the fluid supplied to the annular cage in the direction of the spin axis and in the direction perpendicular to the spin axis was adjusted as follows.

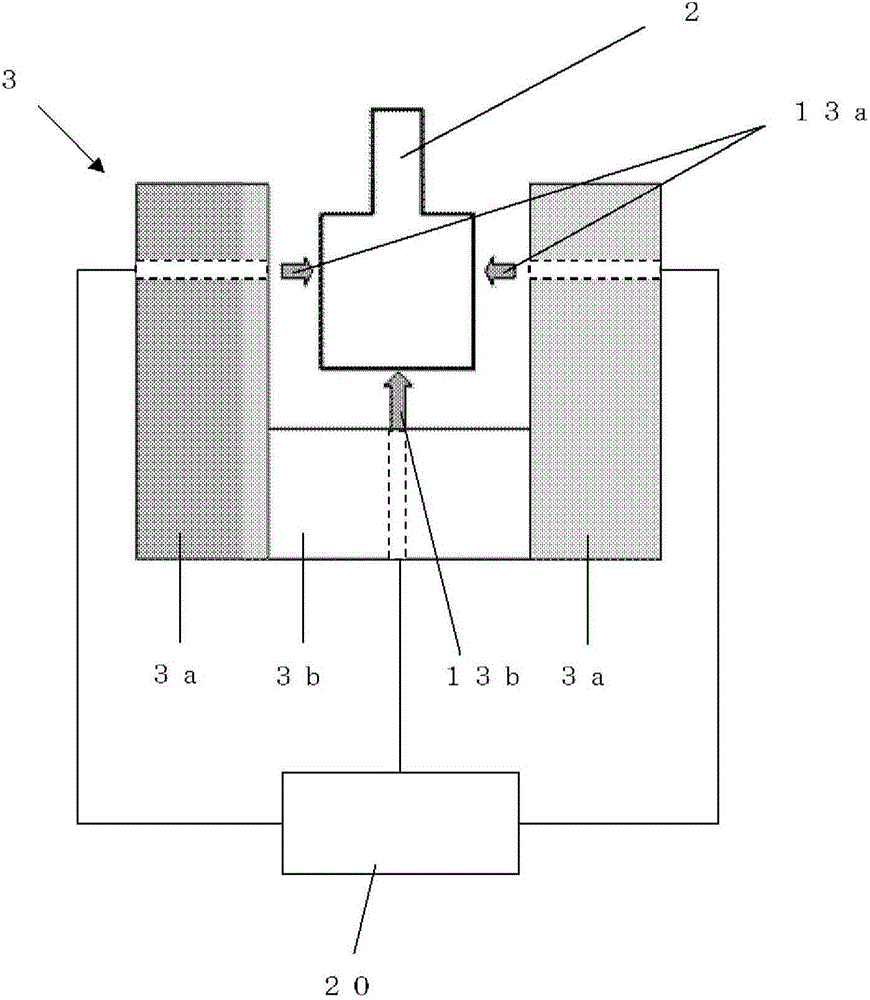

[0072] Such as Figure 4 As shown, in order to measure the displacement of the annular cage, eddy current sensors 21 and 22 are provided. And, apply a load of 10 to 30 Newton (N) from the opposite side of the sensor according to the force gauge, and adjust each supply water pressure to the hydrostatic bearing so that it can be calculated according to the load / displacement (gf / μm) The resulting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com