Composite overlaying manufacturing method of casting roller

A technology for casting rolls and alloy steel, applied in the field of roll manufacturing, can solve problems such as restricting the use range of continuous casting mills, shortening the service life of rolls, increasing production costs, etc., achieving easy surfacing repair, reducing production costs, and improving utilization rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

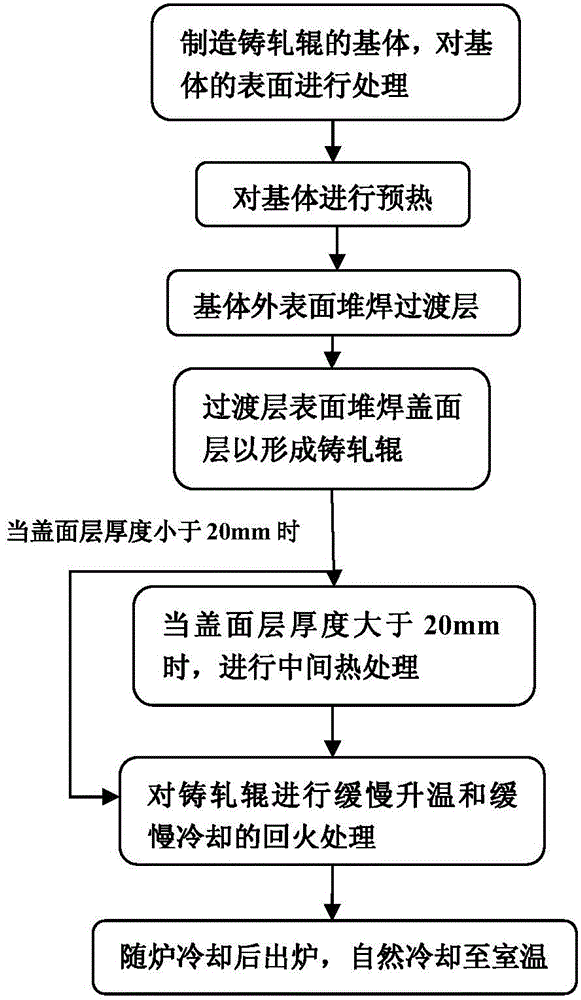

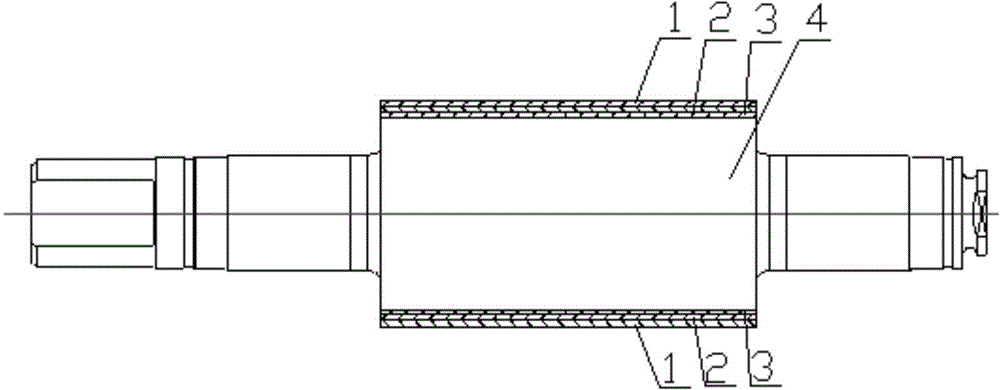

[0037] figure 1 It shows the process flow of the method for manufacturing cast rolls by surfacing welding composite in one embodiment of the present invention. Such as figure 1 As shown, the steps of the surfacing welding compound manufacturing casting roll method include:

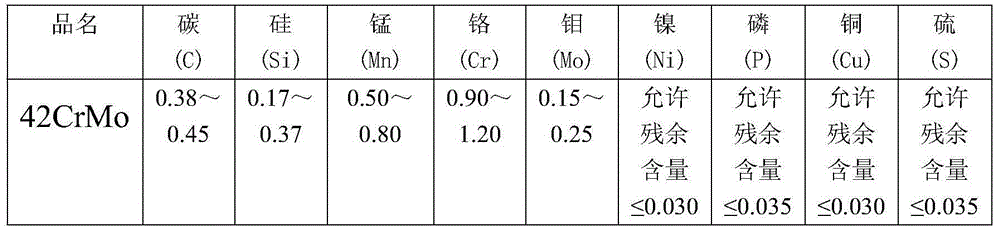

[0038] 1) 42CrMo alloy steel is used to manufacture the roll core of the embodiment of this case (the composition of 42CrMo alloy steel is listed in Table 1), the forging ratio of the substrate is controlled not less than 4:1, and the substrate is quenched and tempered, and then the surface of the substrate is treated Treatment to ensure that the surface and interior of the substrate are free of defects, and turn the surface of the substrate according to actual needs:

[0039]2) Preheat the substrate: preheat the heating rate ≤ 40°C / h, raise it to 200-300°C, keep it warm for 20-30 hours, take the substrate out of the furnace, install retaining rings on both sides of the roll substrate in the axial direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com