Method for manufacturing semicoke for sintering

A semi-coke and production method technology, applied in coke ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of poor air permeability of the material layer, poor mechanical strength of semi-coke, etc., to expand the scope of use, improve air permeability, chemically reactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

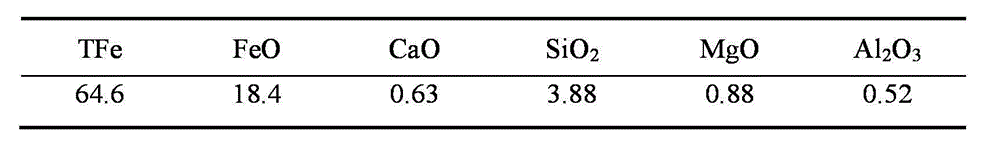

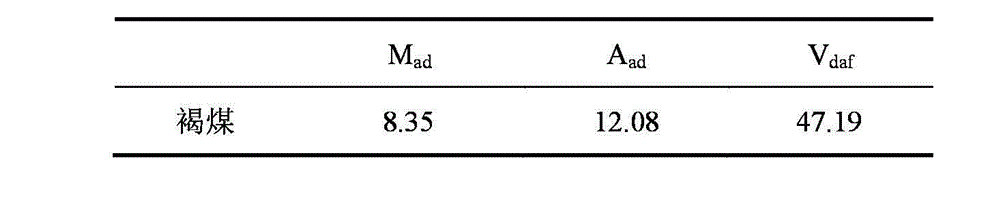

[0018] The mixture is composed of lignite, high-iron and low-silicon iron ore powder and binder asphalt, in which the mass fraction of lignite is 88%, the mass fraction of high-iron and low-silicon iron ore powder is 7%, and the mass fraction of asphalt is 5%. After mixing the mixture evenly , pressed into shape with a double-roller briquetting machine, dry-distilled in a vertical internal heating furnace at 760°C for 10 hours, and then washed with heavy media to obtain 12.4% ash, 10% volatile matter, and 77.6% fixed carbon content Semi-coke for sintering. The components of high-iron-low-silicon iron ore powder and lignite used are shown in Table 1 and Table 2.

[0019] Table 1 Chemical composition of high-iron and low-silicon iron ore powder / %

[0020]

[0021] Table 2 lignite industrial analysis / %

[0022]

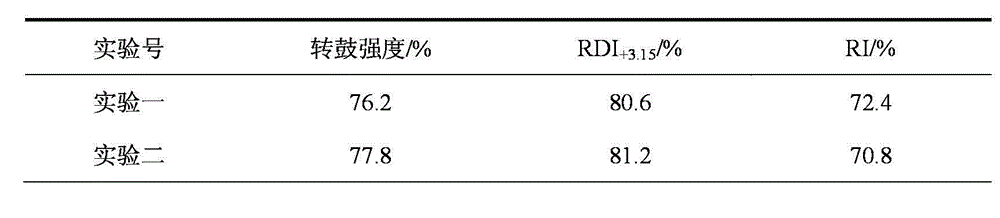

[0023] In the case of the same iron material, add fuel according to the following plan for sintering test: (1) 75% coke powder (50% of coke powder <3mm) is added...

Embodiment 2

[0027] The mixture is composed of low-quality coal (lignite and bituminous coal), high-iron and low-silicon iron ore powder and binder tar residue, in which the mass fraction of inferior coal is 90%, the mass fraction of high-iron and low-silicon iron ore powder is 5%, and the mass fraction of tar residue is 5%, after the mixture is mixed evenly, it is pressed into shape with a pair of roller briquetting machine, and it is dry-distilled in a vertical internal heat furnace at 800°C for 12 hours, and then washed with a heavy medium, and the ash content is 11.6%, and the volatile content is 8. %, semi-coke for sintering with a fixed carbon content of 80.4%, in which the high-iron and low-silicon iron ore powder used is shown in Table 1, and the components of lignite and bituminous coal used are shown in Table 4.

[0028] Table 4 Coal Industry Analysis / %

[0029]

[0030] In the case of the same iron material, the sintering test is carried out with fuel according to the followi...

Embodiment 3

[0034] The mixture is composed of inferior coal (peat, lignite and bituminous coal), high-iron and low-silicon iron ore powder and binder water glass, in which the mass fraction of inferior coal is 85%, the mass fraction of high-iron and low-silicon iron ore is 8%, and the mass fraction of asphalt is The fraction is 7%. After the mixture is mixed evenly, it is pressed into shape with a pair of roller briquetting machines. It is dry-distilled in a vertical internal heat furnace at 820°C for 13 hours, and then washed with heavy media. The ash content is 11.2%, and the volatile matter The semi-coke for sintering with a fixed carbon content of 6% and a fixed carbon content of 82.8%. The high-iron and low-silicon iron ore powder used is shown in Table 1, and the ingredients of lignite and bituminous coal used are shown in Table 6.

[0035] Table 6 Coal Industry Analysis / %

[0036]

[0037] In the case of the same iron material, the sintering test is carried out with fuel accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com