Electric-signal output device and electric-signal output method based on skin

An output device and electrical signal technology, applied in triboelectric generators, medical science, nanoscale sensors, etc., can solve the problems of inconvenience in carrying and use, environmental impact of batteries, large size, etc., and achieve the promotion of wide application, small size, The effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

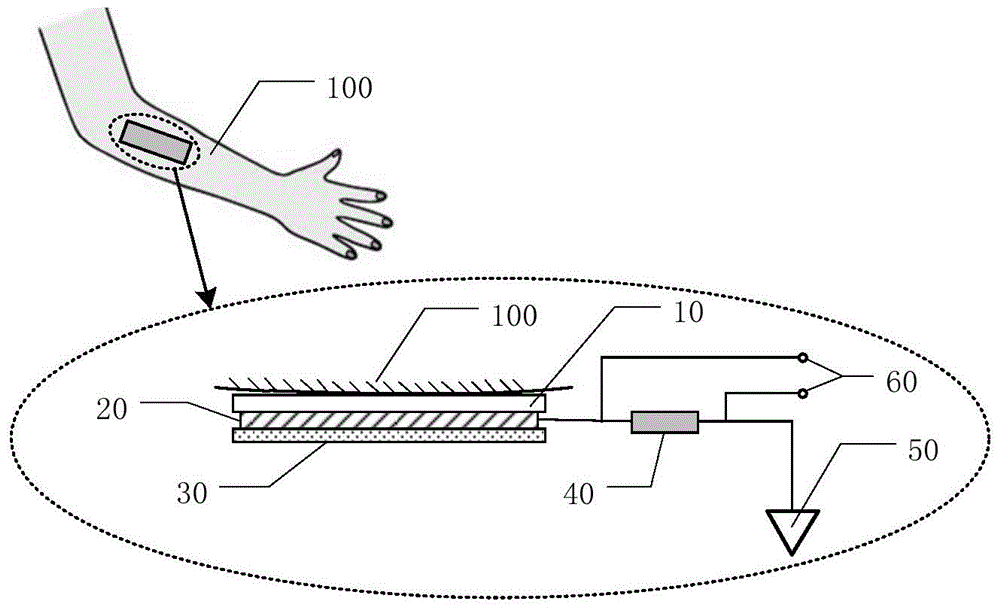

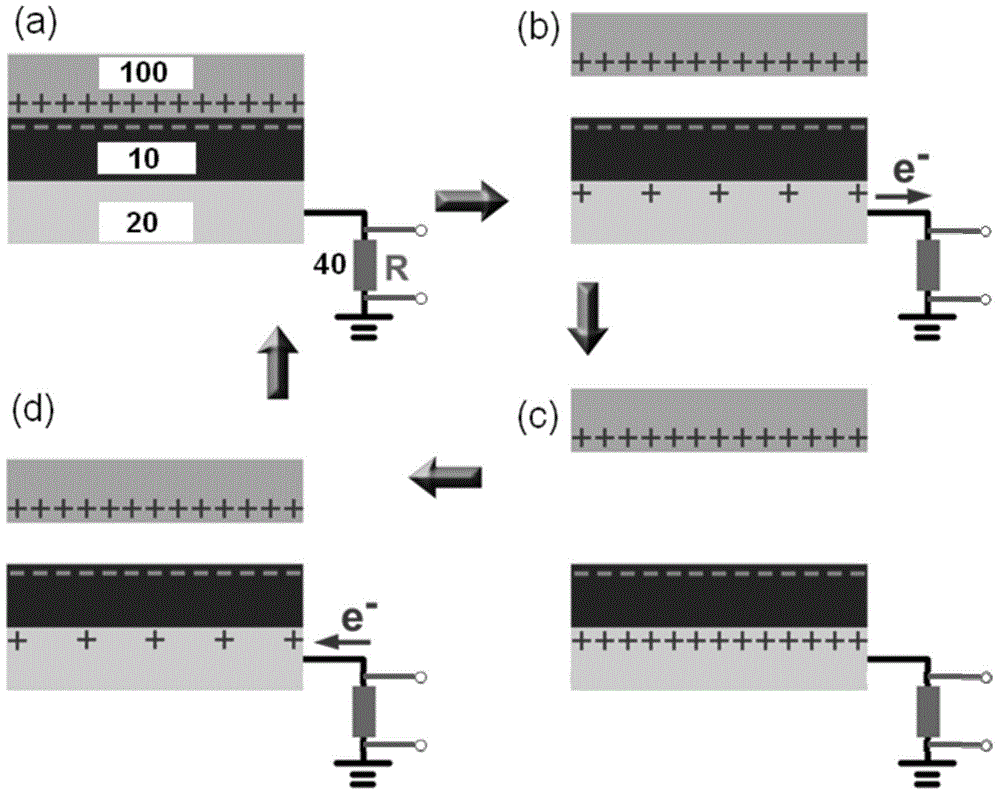

[0106] Cut a 10cm long × 10cm wide × 25μm thick Al foil as an electrode layer, fix it on the separator layer of plexiglass, and make a layer of polymer polydimethylsiloxane by spin coating on the electrode layer (PDMS) as a friction layer. Connect the Al foil to a resistor with a copper wire, and the other end of the resistor is grounded. The copper wire is also connected to a voltmeter. When the polymer layer PDMS is touched by hand, the voltmeter has a corresponding electrical signal output, indicating that it can convert mechanical energy into electrical energy for power generation. When the hand is separated from the polymer-layered PDMS, opposite electrical signals can be observed.

Embodiment 2

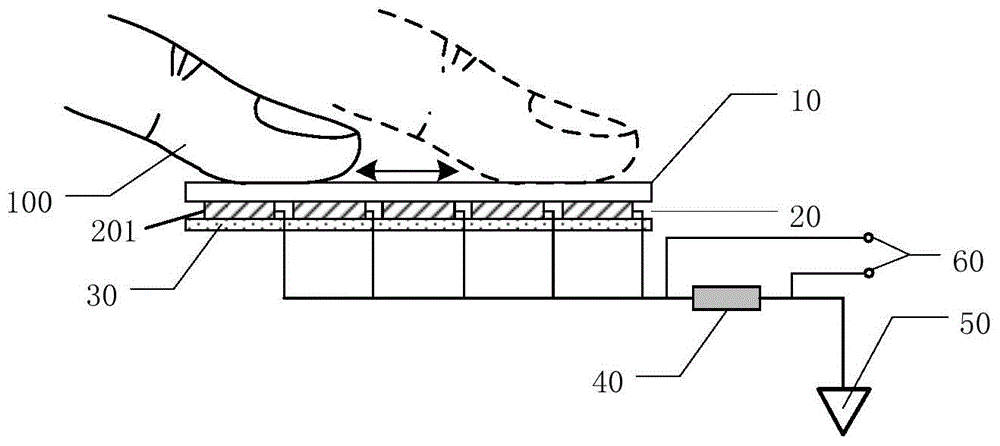

[0108] A plexiglass with a length of 10 cm x a width of 10 cm x a thickness of 1.59 mm was cut by a laser as an insulating layer of the device. Using the method of magnetron sputtering, 16 transparent electrode indium tin oxide (ITO) arrays were fabricated on the substrate, and the size of the electrodes was 1cm long×1cm wide. Use 16 copper wires to connect 16 electrode units respectively, and connect to a resistor, and the other end of the resistor is grounded. 16 copper wires are also connected to the voltage test system, and a layer of polymer material polyimide is made on top of the electrodes to completely cover the entire electrode array, Figure 8 It is a physical photo of the prepared electrical signal output device. When a finger touches the surface of the polymer material on the electrode unit, due to the difference in friction properties between the skin and the polymer layer, an electrical signal can be output to the outside.

Embodiment 3

[0110] The indium tin oxide ITO transparent film was cut by micromachining to prepare 8 electrode units with a length of 0.5cm×a width of 0.5cm×a thickness of 127μm, and they were attached to the surface of the mobile phone touch screen with insulating glue. Each electrode unit was made of The Cu wire leads are electrically connected to the equipotential source through a resistor, and a layer of polydimethylsiloxane (PDMS) film is spread on the surface of the touch screen with the electrode unit attached. The film can cover all the electrode units and pass through the double The surface glue fixes the edge of the PDMS film to the touch screen, see Figure 9 -a photo.

[0111] pass Figure 9 -a It can be seen that after the electrical signal output device is pasted on the screen of the mobile phone, it has no effect on the transparency of the screen. The experiment also proves that the response sensitivity of the mobile phone to various gestures is also completely normal, indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com