Vertical threshing and rotary tillage combined harvester

A combine harvester and vertical technology, which is applied in the direction of harvesters, threshing equipment, cutters, etc., can solve the problems that the grains cannot fall off and damage the grains, the number of combine harvesters is low, and the field is destroyed, so as to achieve a moderate center of gravity, Small size, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

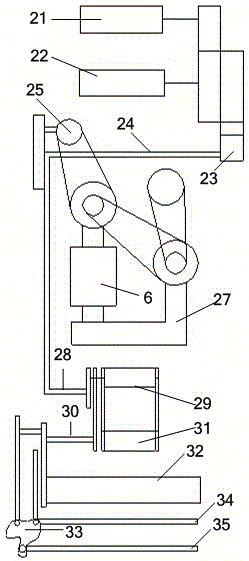

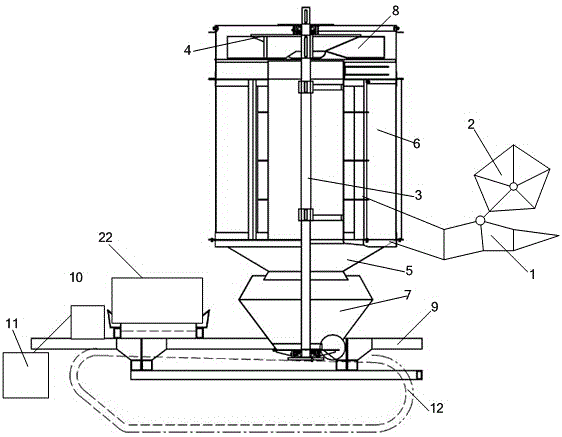

[0015] Such as figure 1 As shown, a vertical threshing and rotary tillage combine harvester includes a grass cutting knife 1, a grain picking wheel 2, a threshing vertical shaft 3, a threshing drum 6, a grain receiver 7, a grass discharge port 8, a beam frame 9, and a gear box 10 and an engine 22, the lower part of the vertical threshing shaft 3 is provided with a grain receiving device 7, a miscellaneous discharge fan 4 and a grass discharge fan 5 from bottom to top, the middle part of the vertical threshing shaft 3 runs through the threshing drum 6, and the top of the vertical threshing shaft 3 is provided with a row Grass mouth 8, the front end of the threshing cylinder 6 is provided with a grass cutting knife 1 and a grain picking wheel 2, the engine 22 and the gear box 10 are arranged on the girder frame 9, the rotary tiller 11 is connected in the gear box 10, and the girder frame 9 lower ends are provided with walking track 12.

[0016] When the harvester is working, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com