Bread refreshment enzyme preparation

An enzyme preparation and bread technology, which is applied in the field of food additives, can solve the problems of easy aging and deterioration of bread, and achieve the effect of anti-aging and fresh-keeping and prolonging the shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

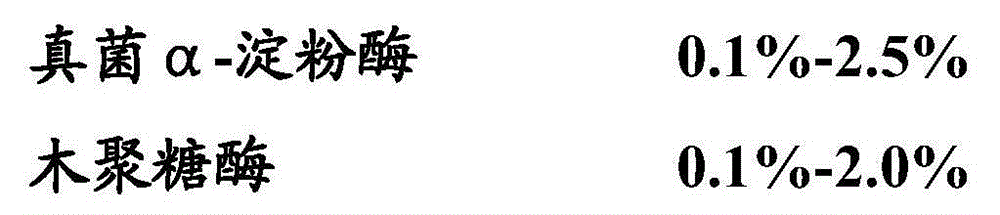

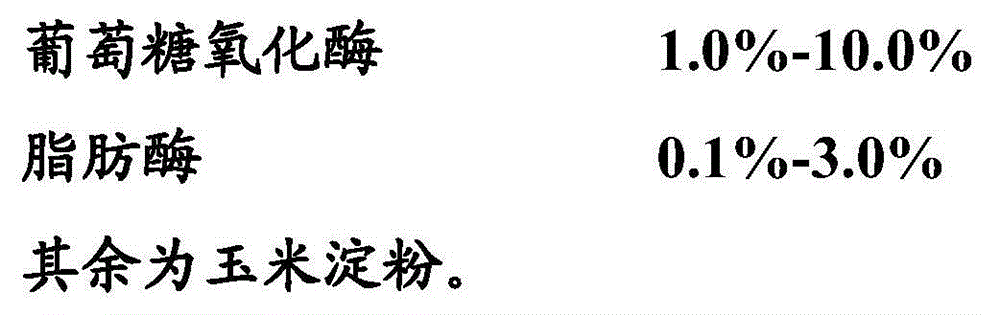

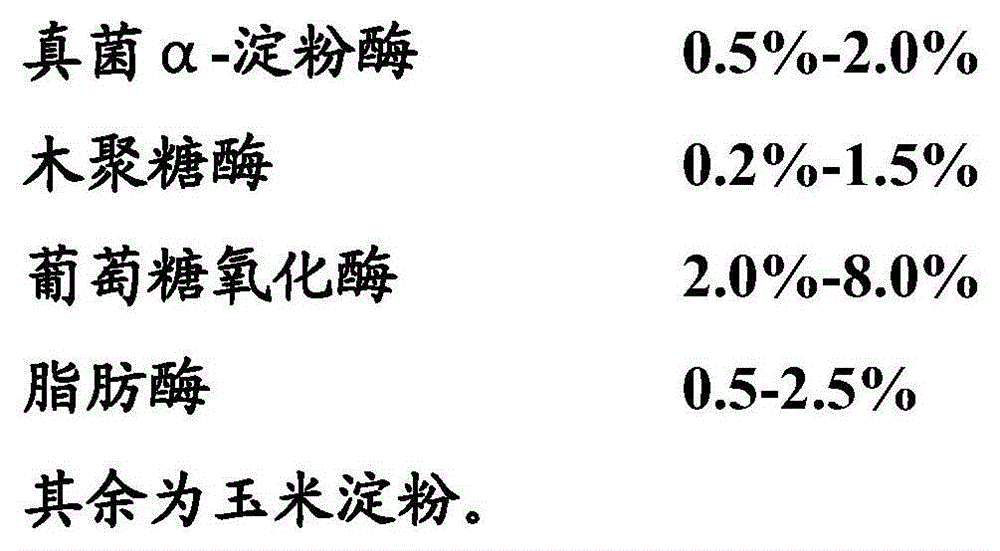

[0027] Weigh each component according to the following mass percentage: 0.5% of fungal α-amylase, 1.8% of xylanase, 8% of glucose oxidase, 0.8% of lipase, 88.9% of cornstarch, add to the mixer and mix evenly, wherein, The enzyme activity of fungal α-amylase is 15000U / g, that of xylanase is 150000U / g, that of glucose oxidase is 150000U / g, and that of lipase is 450000U / g.

Embodiment 2

[0029] Weigh each component according to the following mass percentages: 2.1% fungal α-amylase, 0.3% xylanase, 3% glucose oxidase, 2.4% lipase, 92.2% cornstarch, add to the mixer and mix evenly, wherein, The enzyme activity of fungal α-amylase is 15000U / g, that of xylanase is 150000U / g, that of glucose oxidase is 150000U / g, and that of lipase is 450000U / g.

Embodiment 3

[0031] Weigh each component according to the following mass percentages: 1.2% fungal α-amylase, 0.8% xylanase, 5.0% glucose oxidase, 1.6% lipase, 91.4% cornstarch, add to a mixer and mix evenly, wherein, The enzyme activity of fungal α-amylase is 15000U / g, that of xylanase is 150000U / g, that of glucose oxidase is 150000U / g, and that of lipase is 450000U / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com