Energy-saving electromagnetic heating type tea leaf drying machine

An electromagnetic heating device and drying machine technology, which is applied in tea processing before extraction, etc., can solve the problems of inaccurate temperature control and low thermal efficiency, and achieve the effects of reducing energy loss, high thermal efficiency, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

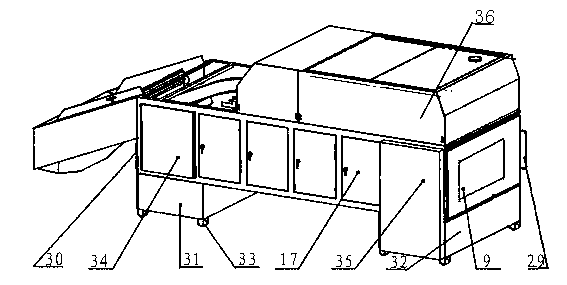

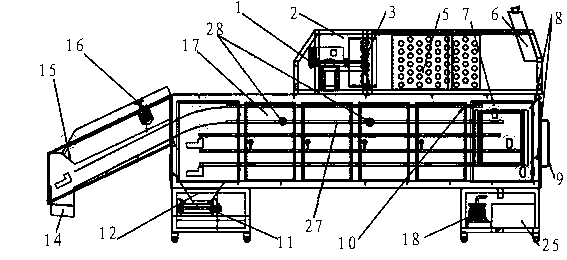

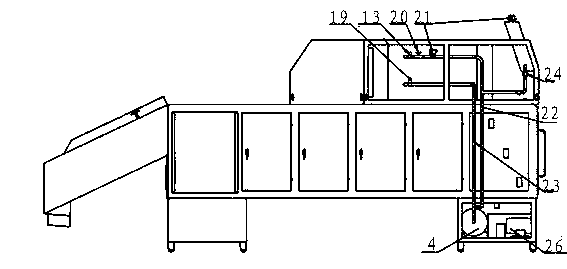

[0021] As shown in the figure, an electromagnetic heating tea energy-saving dryer includes a dryer support structure, an electromagnetic heating hot air generating system, a feeding and conveying system, electrical appliances, and a temperature control system.

[0022] The supporting structure of the dryer mainly includes a dryer main box 30 , a main body front support 31 , a main body rear support 32 , machine feet 33 , a heat preservation door panel 17 , an observation door 9 , a front side door 34 and a rear side door 35 . The front support 31 of the main body and the rear support 32 of the main body are fixedly arranged at the bottom of the main cabinet 30 of the dryer. The machine feet 33 are fixedly arranged on the front support 31 of the main body and the bottom of the rear support 32 of the main body. The heat preservation door panels 17 are fixedly arranged on the front and back sides of the main box body 30 of the dryer. The observation door 9 is arranged on the rig...

Embodiment 2

[0028] First turn on the main power switch of the electric control cabinet 29 of the electromagnetic heating tea energy-saving dryer and the main power switch of the electromagnetic heating controller 25, set the temperature required for the drying operation, and then start the electromagnetic heating operation power supply and the feeding and conveying system successively When the power is turned on, the electromagnetic heating device 4 immediately starts to heat the heat transfer oil, heats the air through the oil-air exchanger 5, and blows it into the main box body 30 of the dryer by the axial flow fan 3. When the temperature reaches the set value, the product in process is poured into the feeding and conveying system, and the feeding speed is adjusted through the speed control switch on the main control cabinet 29 to make it reach the best state. The in-progress product is evenly sent into the main box body 30 of the dryer through the uniform leaf device 16 of the feeding c...

Embodiment 3

[0030] When the new electromagnetic heating tea energy-saving dryer is used for drying operation, the drying temperature is set to 115°C through the control device, and the speed of the chain plate is adjusted to 700rpm, and the wind speed is 10m / s. After the temperature reaches the set value, the curly-shaped green tea in-process with a moisture content of 13% is put in from the feeding place, and the in-process green tea advances with the punching chain plate in the box, gradually falls from the upper layer to the lower layer, and finally is output from the conveyor belt In this process, the water is evaporated by hot air to achieve the purpose of dryness.

[0031] Table 1 Sensory evaluation results of tea samples with different drying treatments

[0032]

[0033] Note: Biluochun dryer is used in traditional drying equipment.

[0034] From the sensory evaluation results of tea samples with different treatments in the implementation examples, it can be seen that after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com