Rice processing system having reduced rate of broken rice

A rice processing and broken rice rate technology, which is applied in the direction of grain germ removal, grain processing, and grain milling, can solve the problems of affecting the uniformity of rice, affecting the quality of rice cooking, eating quality, storage quality, and large starch loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

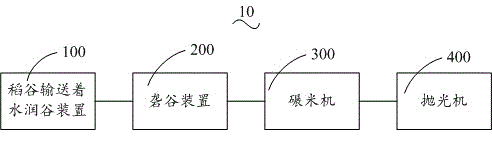

[0016] Please see also figure 1 , the rice processing system 10 that reduces the rate of broken rice comprises paddy conveying water moistening device 100, rice husking device 200, rice milling machine 300, polishing machine 400, and rice conveying water moistening device 100 is used for cleaning the paddy water, and make the moisture adhered on the surface of the paddy penetrate into the inside of the rice husk and the brown rice quickly; The husk is taken off, and the chaff is separated from the brown rice; the rice mill 300 is used to whiten the brown rice delivered by the huller 200 to obtain white rice; the polishing machine 400 is used to polish the white rice delivered by the rice mill 300 to obtain a color Crystal clear polished rice.

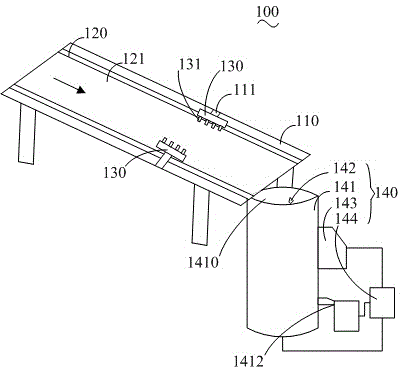

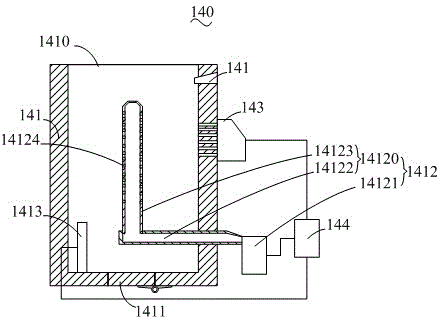

[0017] Please see also figure 2 and image 3, the paddy is transported with water moistening device 100 and comprises support frame 110, belt conveyor 120, micron spray device 130, grain moistening device 140, belt conveyor 120 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com