Simple screening equipment of legume crops

A technology for screening equipment and crops, applied in the direction of sieve, solid separation, grid, etc., can solve the problems of high manufacturing cost, high labor intensity, complex structure, etc., and achieve the effect of low cost, simple structure and great promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

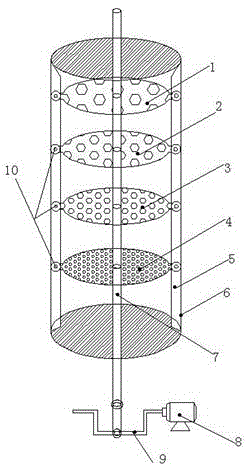

[0014] Such as figure 1 As shown, a multi-stage bean crop vibrating screening machine, its structure includes: a first-level screen 1, a second-level screen 2, a third-level screen 3, a fourth-level screen 4, slide rails 5, and an outer cylinder wall 6 , Transmission spindle 7, motor 8, crankshaft 9, roller 10.

[0015] Such as figure 1 As shown, the motor 8 is connected to the crankshaft 9, and the crankshaft 9 is connected to the transmission spindle 7 through a connecting shaft. When the motor 8 drives the crankshaft 9 to rotate, the crankshaft 9 drives the transmission spindle 7 to move up and down.

[0016] Such as figure 1 As shown, the drive mandrel 7 is sequentially installed with a first-level mesh screen 1, a second-level mesh screen 2, a third-level mesh screen 3 and a fourth-level mesh screen 4 from top to bottom. 2. The empty holes on the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com