Method for preparing metal layered micro-gradient composite material

A composite material and metal composite plate technology, which is applied in the direction of metal rolling, rolling force/roll gap control, etc., to achieve the effect of simple process and broad application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

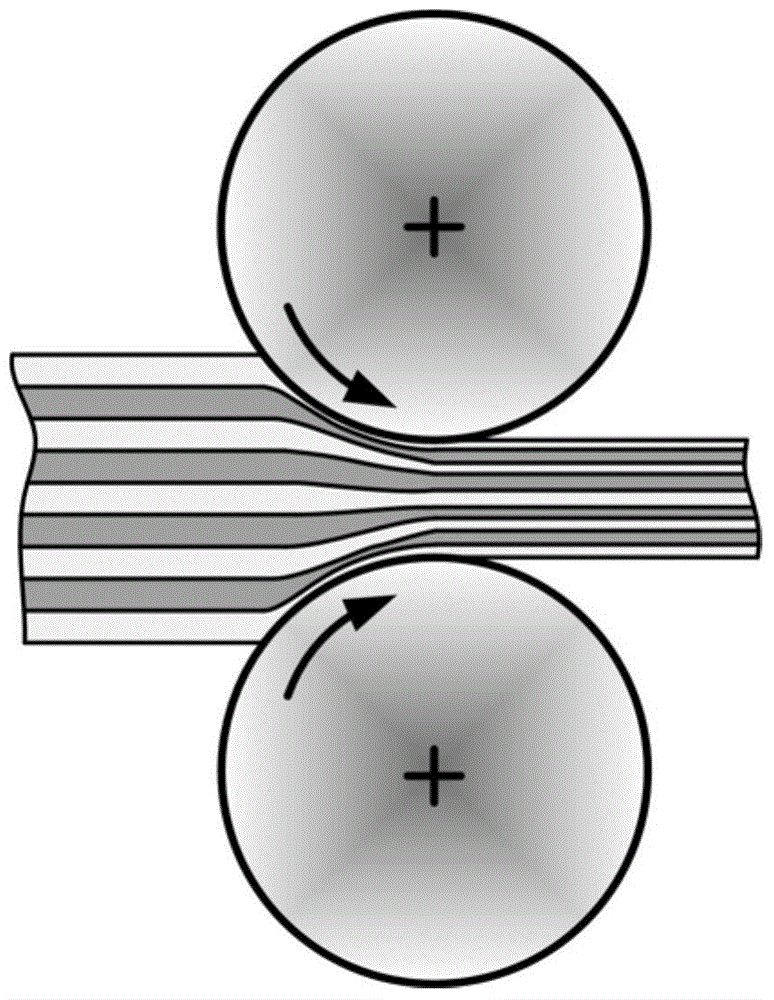

[0025] A method for preparing a metal layered microgradient composite material, comprising the following steps:

[0026] 1) Pre-treatment of metal sheets: prepare two kinds of metal sheets, which are denoted as sheet metal I and sheet metal II respectively. Sheet metal I and sheet metal II have the same or similar thickness. In the embodiment, the metal plate I is a soft metal with a thickness of about 1-3 mm; the metal plate II is a hard metal with a thickness of about 1-3 mm. . Sheet metal Ⅰ and sheet metal Ⅱ belong to the same alloy series, but the contents of the main alloying elements are different.

[0027] Preferably, the difference in the main alloying elements of the two sheets is significant. For example, the metal plate I is selected from industrial pure aluminum 1100 or industrial pure aluminum 1050; the metal plate II is selected from aluminum alloy 7050 or aluminum alloy 7075.

[0028] For example, the content (%) of alloying elements in industrial pure alumi...

Embodiment 2

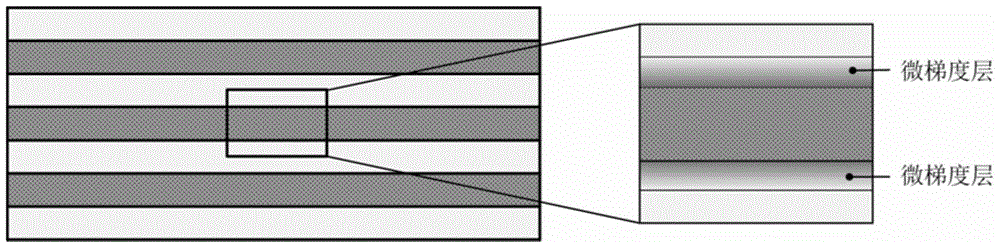

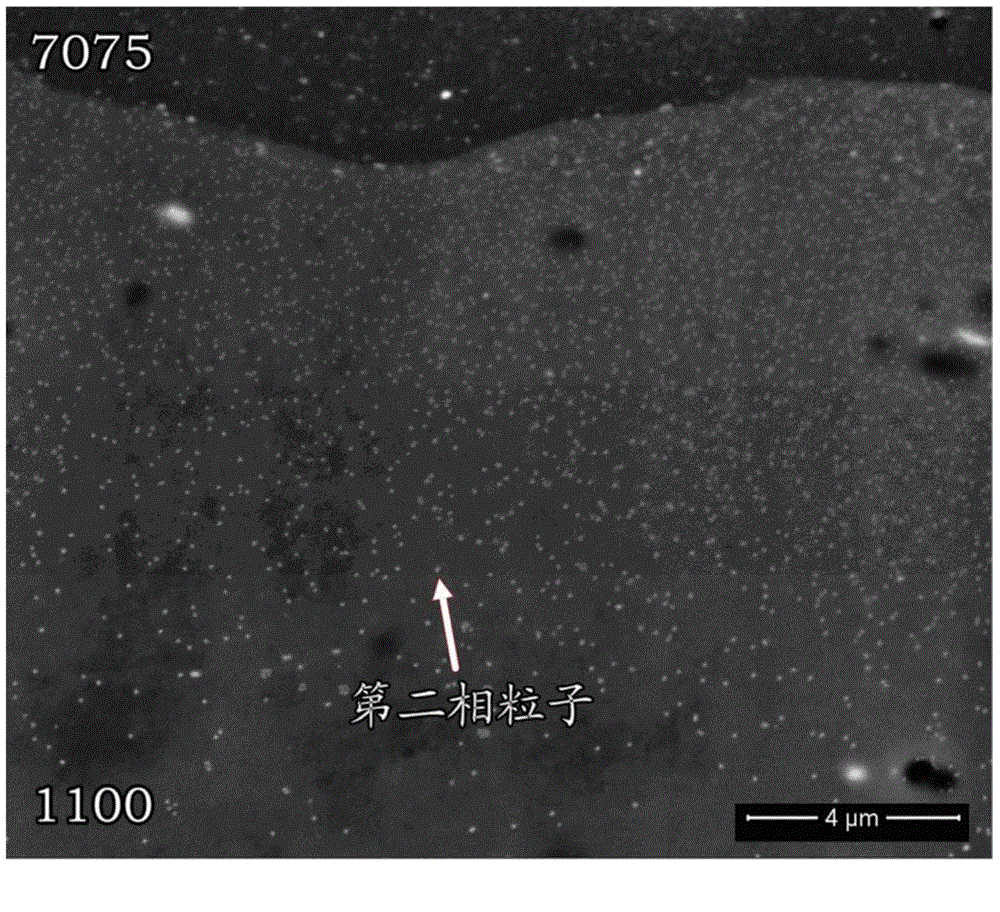

[0047]Select metal plates made of the same series of aluminum alloys. The material of metal plate I is industrial pure aluminum 1100, and the material of metal plate II is high-strength aluminum alloy 7075. The thickness of metal plate Ⅰ and metal plate Ⅱ are both 1 mm, the content of alloy elements in the former is low, and the content of alloy elements in the latter is high. Perform annealing pretreatment on metal plate I and metal plate II, metal plate I1100 was annealed at 300 ° C for 1 h, metal plate II 7075 was annealed at 350 ° C for 2 h, and then taken out and cooled to room temperature. Surface treatment of the two metals, using a stainless steel brush with a diameter of 0.2mm for grinding to ensure uniform grinding, then rinse the surface with clean water, and dry the surface with a hair dryer. Follow the order of 1100 / 7075 / 1100 / 7075 / 1100 for 5-layer lamination, use aluminum nails to rivet and fix the four corners, and the total thickness of the 5-layer blank is abo...

Embodiment 3

[0049] Select metal plates made of the same series of aluminum alloys. The material of metal plate I is industrial pure aluminum 1050, and the material of metal plate II is high-strength aluminum alloy 7050. The thickness of metal plate Ⅰ and metal plate Ⅱ are both 1 mm, the content of alloy elements in the former is low, and the content of alloy elements in the latter is high. Perform annealing pretreatment on metal plate I and metal plate II, metal plate I1050 was annealed at 300 ° C for 1 h, metal plate II 7050 was annealed at 350 ° C for 2 h, and then taken out and cooled to room temperature. Surface treatment is carried out on the two metal plates, and the stainless steel brush with a diameter of 0.2mm is used for grinding to ensure that the grinding degree is uniform, and then the surface is rinsed with clean water, and the surface is dried with a hair dryer. Laminate 7 layers in the order of 1050 / 7050 / 1050 / 7050 / 1050 / 7050 / 1050, use aluminum nails to rivet and fix the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com