Automatic control system and method for strip steel surface rust removal

An automatic control system and strip steel technology, applied in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve problems such as large loss, pollution, and difficult disposal of waste acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

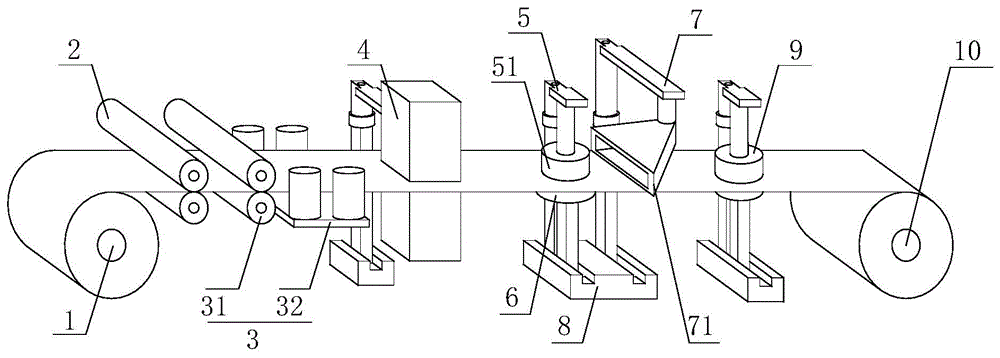

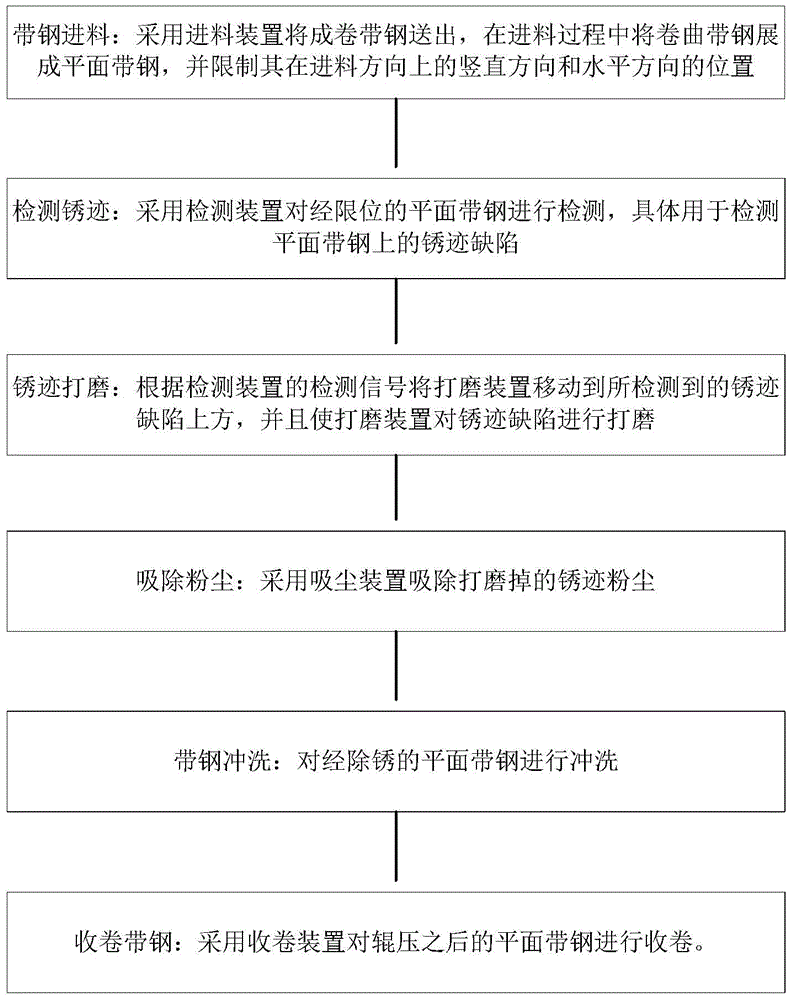

[0029] like figure 1 as shown, figure 1 It is a schematic structural view of a strip steel surface derusting automatic control system proposed by the present invention, figure 2 for figure 1 The method flow chart of the automatic control method of the automatic control system.

[0030] refer to figure 2 , a kind of strip steel surface derusting automatic control method that the present invention proposes, comprises the following steps: strip steel feeds, detects rust stain, rust stain polishes, sucks and removes dust, strip steel washes, coils strip steel;

[0031] Strip feeding: the coiled strip is sent out by the feeding device, and the coiled strip is developed into a flat strip during the feeding process, and its vertical and horizontal positions in the feeding direction are limited;

[0032] Rust detection: the detection device is used to detect the limited flat strip steel, which is specifically used to detect rust defects on the flat strip steel;

[0033] Rust gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com