Cold heading forming manufacturing method for piston part of refrigeration compressor

A technology for refrigeration compressors and piston components, applied in the direction of pistons, etc., can solve the problems of heavy product weight, high manufacturing cost, and powder handling by workers, and achieve the effects of light product weight, low manufacturing cost, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

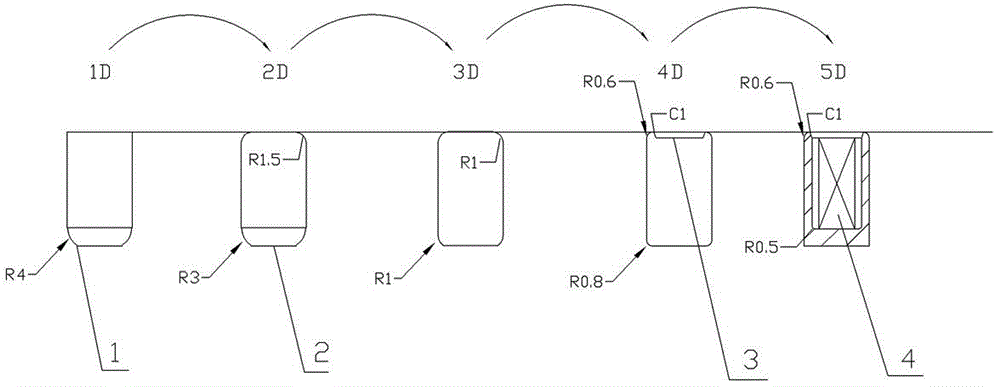

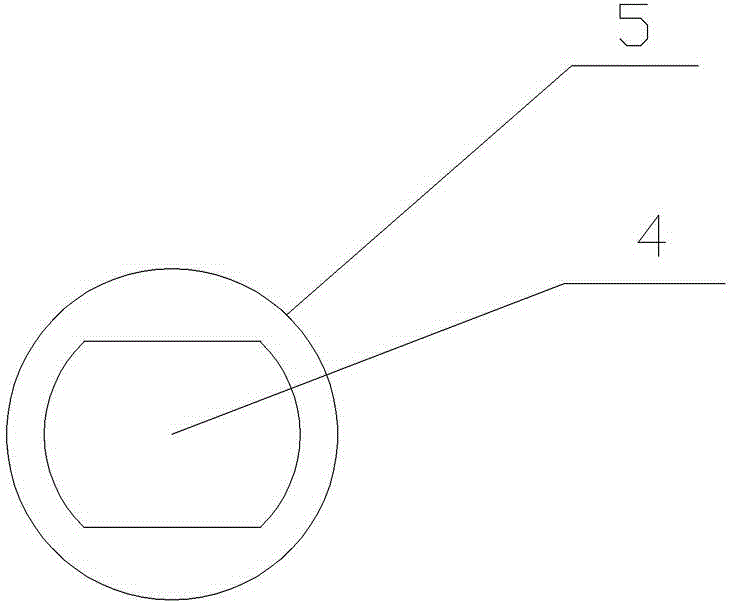

[0017] like figure 1 Shown, a kind of refrigeration compressor piston parts cold heading forming manufacturing method, comprises the following steps:

[0018] (1) Use the cutting mechanism of the multi-station forming machine to cut the metal raw material rod into the required length metal segment 5, and transport it to the next station;

[0019] (2) The metal segment processed in step (1) is pressed into the first die opening through the first front punch, and the A end 1 of the metal segment is subjected to cold heading shaping, so that the A end of the metal segment forms a rounded corner with a radius of 4mm , and then transported to the next station through the ejection of the first rear punch;

[0020] (3) The metal segment processed in step (2) is pressed into the second die opening by the second front punch for cold hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com