A material boat turning and receiving device

A material receiving device and material boat technology, which is applied in the field of material boat flipping and receiving devices, can solve the problems of narrowing the working space, occupying a large working space, and complexity, and achieves the simplification of the device and operation process, avoiding pollution, and thorough material receiving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

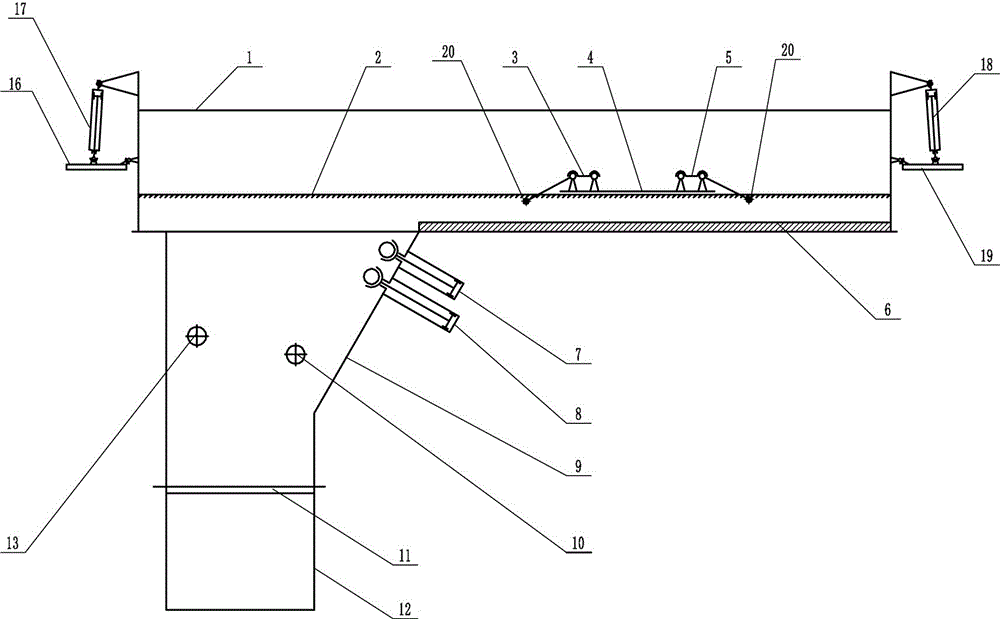

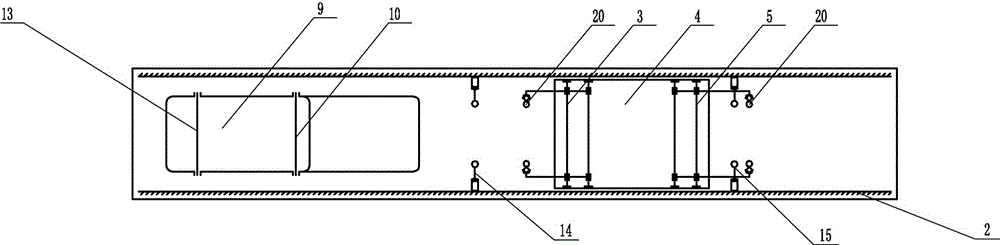

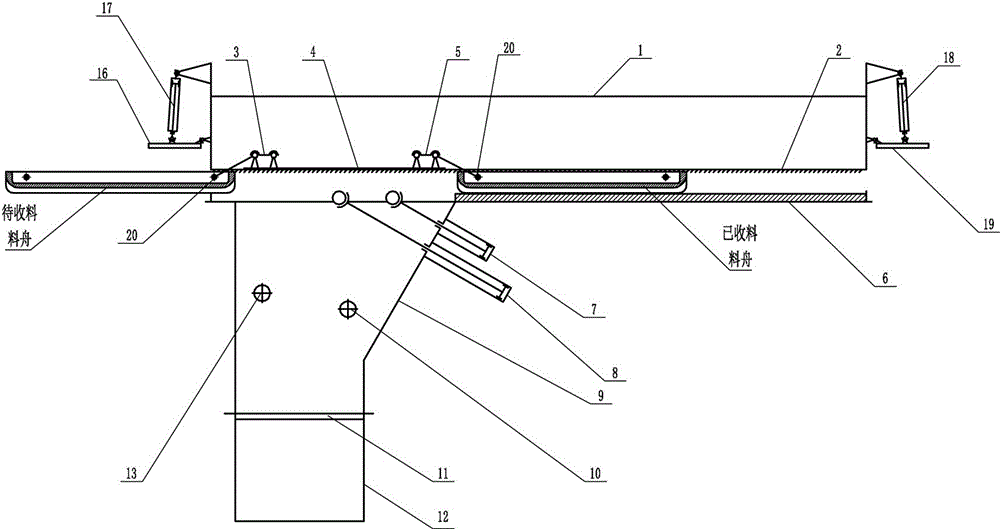

[0038] A material boat flipping and receiving device, such as Figure 1 to Figure 2 As shown, it includes sealing assembly, material boat support guide groove 6, guide rail 2, material boat front positioning device 14, material boat rear positioning device 15, clip boat assembly, material receiving bin 9, negative pressure vacuum cleaner 11 and material powder collection bucket 12;

[0039] Described sealing assembly comprises rear hatch door cylinder 18, front hatch door cylinder 17, back seal hatch 19, front seal hatch 16 and seal cover 1; Connect, the rear airtight door 19 is connected with the airtight cover 1 by the air cylinder 18 of the rear door;

[0040] Described material boat support guide groove 6 is arranged on the bottom of sealing cover 1, and above material boat support guide groove 6 is provided with described guide rail 2, and described guide rail 2 is provided with material boat front positioning device 14 and material boat rear positioning device 15 The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com