Laser scribing method reducing chip physical stress damage

A laser scribing and physical stress technology, applied in laser welding equipment, electrical components, circuits, etc., can solve the problems of inability to mass-produce Flash products, hinder the application and promotion of laser scribing, damage Flash products, etc., and achieve yield Improve, reduce impact, reduce the effect of damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

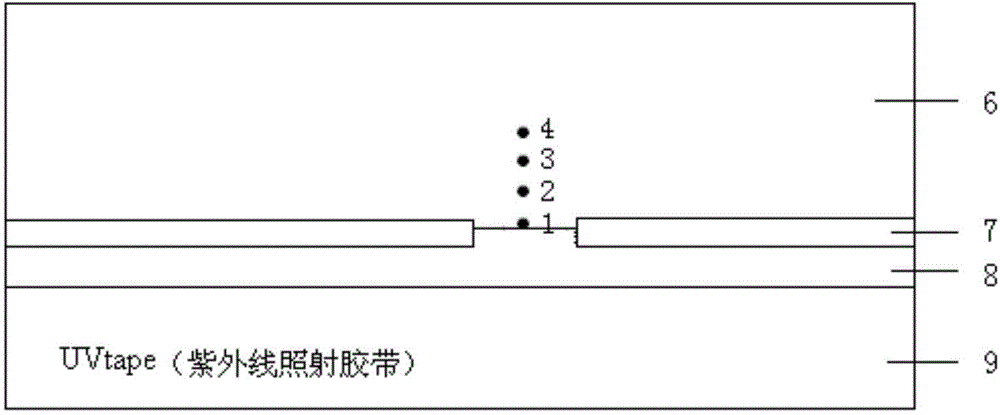

[0010] Referring to the accompanying drawings, the laser scribing method that reduces the chip damage by physical stress is:

[0011] Put the thinned wafer with the back of the wafer (6 indicates the wafer monocrystalline silicon substrate) facing up and the front (7 indicates the effective layer of the chip circuit on the front of the wafer) facing down, and pass through the UV tape (ultraviolet irradiation tape). The covered UV glue (shadowless glue) (8 indicates the UV adhesive layer covered by UV tape) is applied on the UV film (ultraviolet film) [9 indicates the PC (polycarbonate) film layer of UVtape]; the back of the wafer faces The laser source is incident from the back of the wafer to perform scribing, and the first laser scan focuses on the front surface of the wafer scribing lane. 1 in the figure indicates the position of the focus point of the first laser scanning in the scribing track, and 2, 3, 4, etc. respectively indicate the longitudinal position and order of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com