Method for preparing polyvinyl butyral layer structure utilizing waste glass

A technology of polyvinyl butyral and waste glass, which is applied in the direction of recycling technology, chemical instruments and methods, synthetic resin layered products, etc., and can solve the problem of untaught polyvinyl butyral polymer organic matter recycling and reuse, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

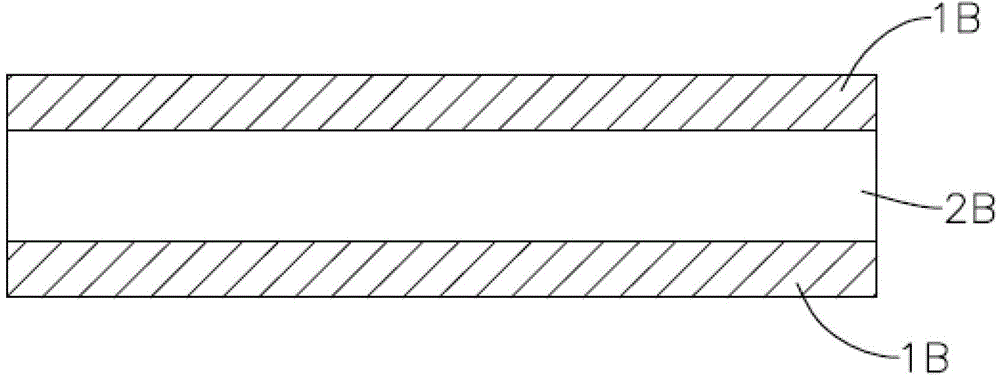

[0085] First, a waste glass is provided, which contains glass, polyvinyl butyral and a small amount of unnecessary impurities. Based on the whole waste glass, the content of polyvinyl butyral is about 10% by weight; the content of glass is about 87% by weight; the content of unnecessary impurities such as sludge is about 3% by weight. In this embodiment, the waste glass is a waste automobile safety glass, and its layered structure includes two glass plates and a polyvinyl butyral film sandwiched between the glass plates.

[0086] Next, use the rolling force of 200kgf to destroy the waste glass by roller compaction to obtain a plurality of crushed waste glass; then use a tearing machine to separate the crushed waste glass with a tearing force of 7000kgf , to obtain multiple scrap glass shards.

[0087] Here, after the waste glass to be processed in this embodiment undergoes the above-mentioned rolling and tearing steps, the processed waste glass is composed of a plurality of w...

Embodiment 2

[0101] In this example, the polyvinyl butyral material was recovered from waste glass roughly by the method described in Example 1; in addition, 4 mm polyvinyl butyral particles were obtained through drying and kneading steps .

[0102] The difference is that in this embodiment, the calendering step is carried out with four rubber rollers at a temperature of 140° C. with a calendering force of 25 kgf and a calendering rate of 60 m / min, thereby making the above-mentioned polyvinyl butyral The rubber particles are calendered to form a polyvinyl butyral layer.

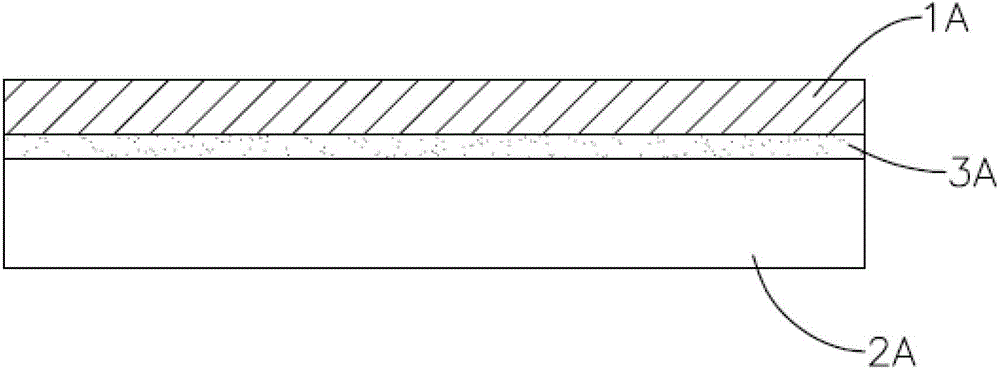

[0103] Next, prepare a fabric layer with an adhesive layer on its surface, and collect the fabric layer with an adhesive layer on a roller, and collect the polyvinyl butyral layer prepared above on another roller, And make the adhesive layer on the fabric layer close to the polyvinyl butyral layer to be bonded, and make the fabric layer and the poly The vinyl butyral layers are attached to each other through the adhesiv...

Embodiment 3

[0106] In this example, the polyvinyl butyral material is recovered from waste glass through the method described in Example 2; in addition, through drying, kneading, calendering and other steps, a bonded polyvinyl butyral material is obtained. Aldehyde fabric layer.

[0107] Then, the fabric layer pasted with the polyvinyl butyral layer was collected on a roller, and the polyvinyl butyral layer obtained in Example 1 was collected on another roller, and the polyvinyl butyral layer was collected on another roller, and the The bonding force, the bonding temperature of 140°C, and the bonding speed of 30 m / min make the fabric layer bonded with the polyvinyl butyral layer and the polyvinyl butyral collected on another roller The layers are attached to each other to form a polyvinyl butyral layered structure. Here, when the fabric layer pasted with the polyvinyl butyral layer is collected and pasted with the polyvinyl butyral layer on another roller, the polyvinyl butyral layer on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com