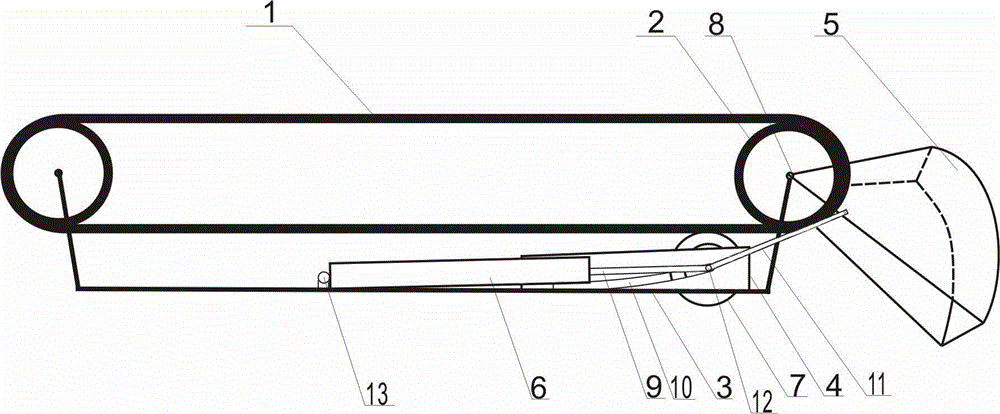

Automatic cleaning device of conveyor belt

An automatic cleaning and conveyor belt technology, applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of occupying production space, inconvenient fertilization, waste of raw materials, etc., to achieve convenient installation and operation, avoid corrosion, maintain Clean and hygienic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1. During normal production, the hydraulic pump (6) starts to push the olive-shaped rolling brush forward and upward along the track groove, and simultaneously supports the shroud in front of the end waist roller, and starts the motor to drive the brush body to run at high speed. Remove the adherents adhering to the return belt in time, or clean it in time according to the needs, that is, the pneumatic hydraulic pump retracts the push-pull rod to separate the brush body from the return belt, turns off the motor, and at the same time the shroud is folded back, in the position of The bottom of the end waist roller does not affect the feeding of the conveyor belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com