Synchronous anti-slip balanced lifting clamp forceps

A balance lifting and clamping technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve problems such as falling off, lifting objects out of balance, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

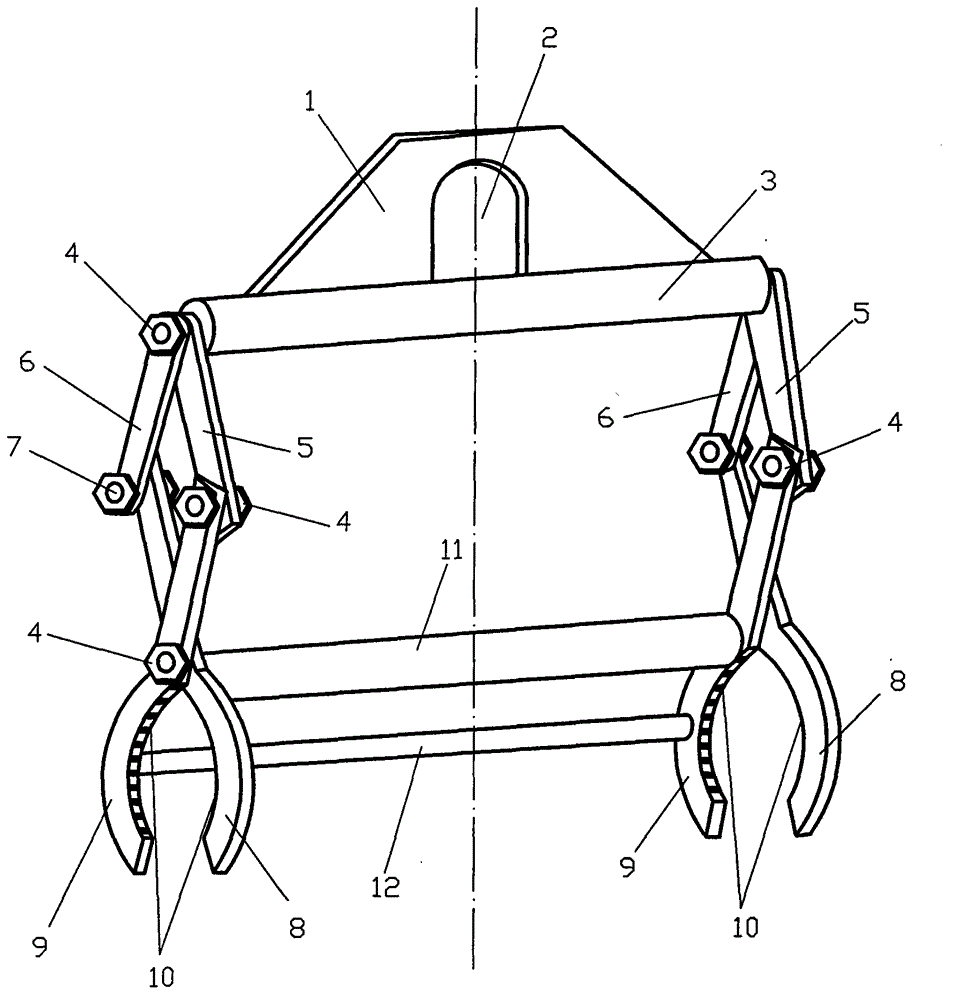

[0007] As shown in the figure, the synchronous non-slip balanced lifting clamp is composed of a hanging beam 1, a lifting hole 2, a balance shaft beam 1 3, a locknut 4, a connecting rod 5, a connecting rod 2 6, and stud bolts. 7. Composed of front clip 8, rear clip 9, rubber pad 10, balance shaft beam 2 11, and synchronous bridge shaft 12; it is characterized in that the shape of the hanging beam 1 is isosceles trapezoidal, and the center of the hanging beam 1 is provided with an arched hanging hole 2 , the arc quadrant point of lifting hole 2 is located at the center line of the overall structure of the synchronous anti-slip balanced lifting clamp, the bottom edge of lifting beam 1 is welded on the balance shaft beam 1 3, and the two ends of the balance shaft beam 1 3 are equipped with wire heads, and the balance The wire heads at the two ends of the axle beam one 3 pass through the holes provided at one end of the connecting rod one 5 and the connecting rod two 6, and then fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com