Wet desulfurization absorption tower and self-cleaning flue gas dust removal system thereof

A dust removal system and self-cleaning technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of high dust removal efficiency, large floor area, small dust particle size, etc., to reduce operating costs and maintenance costs Low and low running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

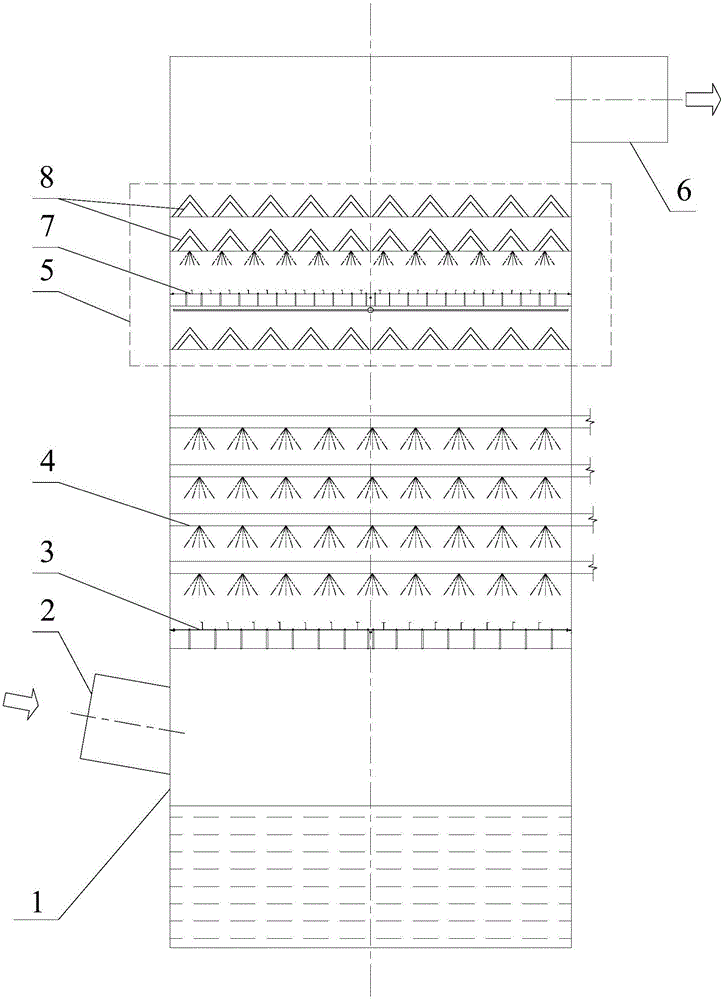

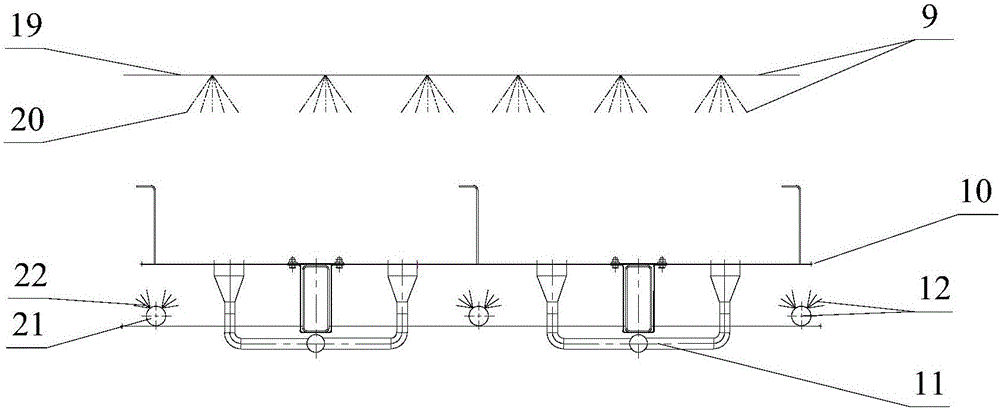

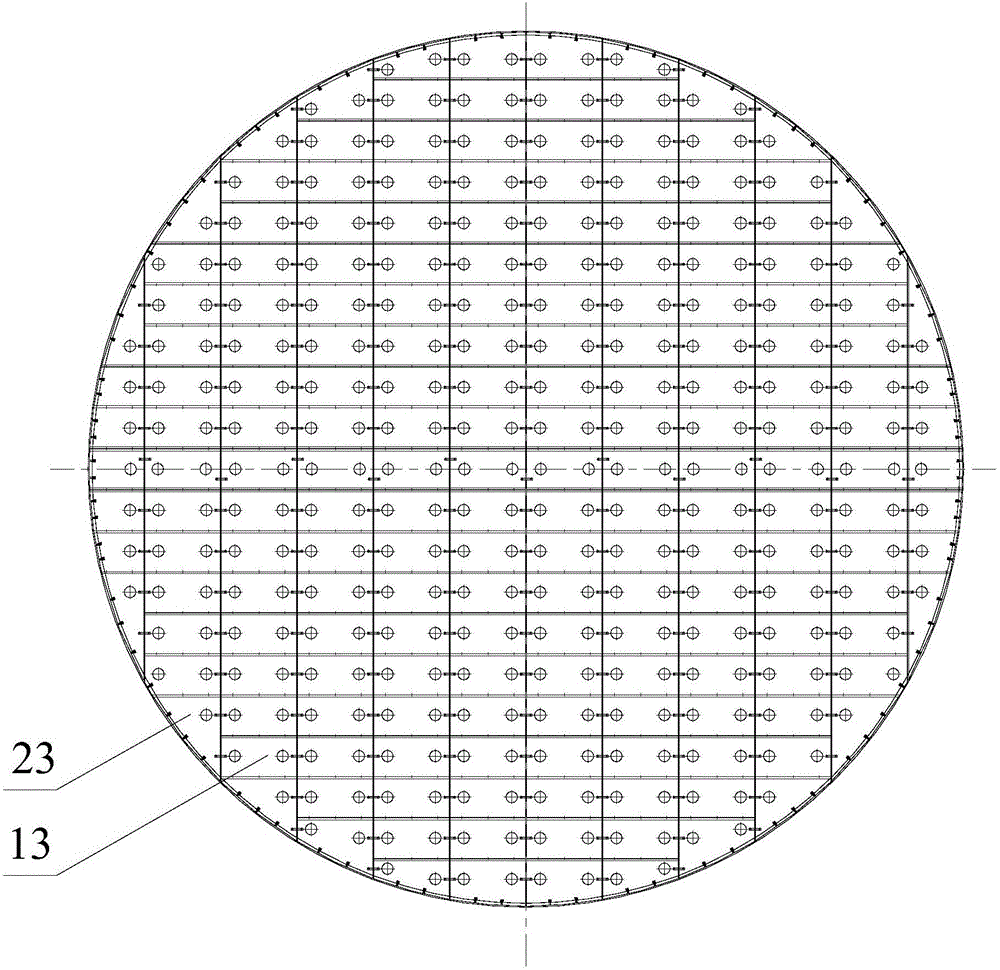

[0046] A wet desulfurization absorption tower, such as figure 1 As shown, the self-cleaning flue gas dust removal system 5 is arranged inside the absorption tower 1. The lower part of the absorption tower 1 is provided with a flue gas inlet 2, and the upper part is provided with a flue gas outlet 6. The flue gas inlet in the absorption tower 1 is Between 2 and the flue gas outlet 6, a through-flow sieve plate 3, a spray area 4, and a self-cleaning flue gas dust removal system 5 are arranged in sequence from bottom to top. The self-cleaning flue gas dedusting system 5 is arranged between the uppermost spray area and the flue gas outlet 6 . The flue gas enters the through-flow sieve plate 3 from the flue gas inlet of the absorption tower, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com