Combustion device having automatic phosphorus-adding function

A technology of combustion device and function, applied in the field of phosphorus chemical industry, can solve the problems of waste of raw materials, throwing, harming workers' bodies, etc., and achieve the effects of saving energy, simple operation and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

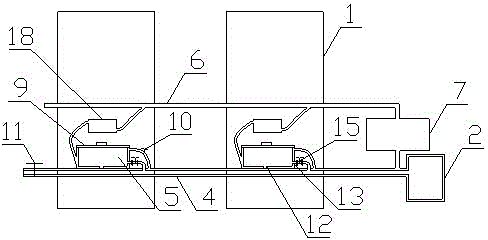

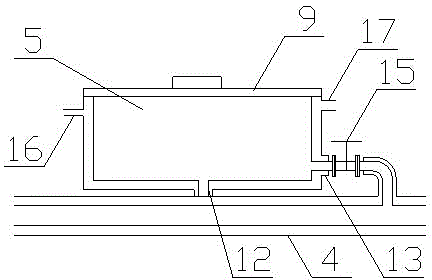

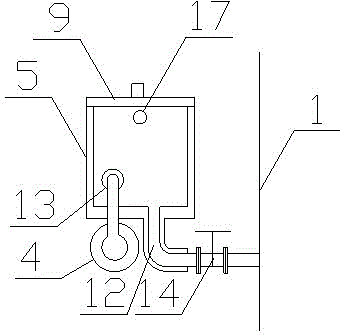

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] see Figure 1-3 , the embodiment of the present invention provides a combustion device with automatic phosphorus addition function, the device includes a combustion furnace 1 connected to the elevated tank 2 through a phosphorus delivery pipeline 4, a phosphor bucket 5 connected to the combustion disc of the combustion furnace 1, a heating The water circulation tank 7 and at least one hot water bag 18 arranged on the combustion chamber 1 and the like. Among them, a plurality of combustion furnaces 1 are arranged side by side, usually 5 or 10 combustion furnaces are a group, and the phosphorus delivery pipeline is arranged horizontally at the position of the left and right heights of the combustion disc of the combustion furnace 1, and is close to the combus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com