A kind of high zirconium borosilicate glass and preparation method thereof

A silicate glass, high zirconium boron technology, applied in the field of high zirconium borosilicate glass and its preparation, can solve the problems of poor glass uniformity, difficult engineering, small size, etc., achieve large negative anomalous dispersion, high Optical uniformity, the effect of solving the problem of high temperature precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

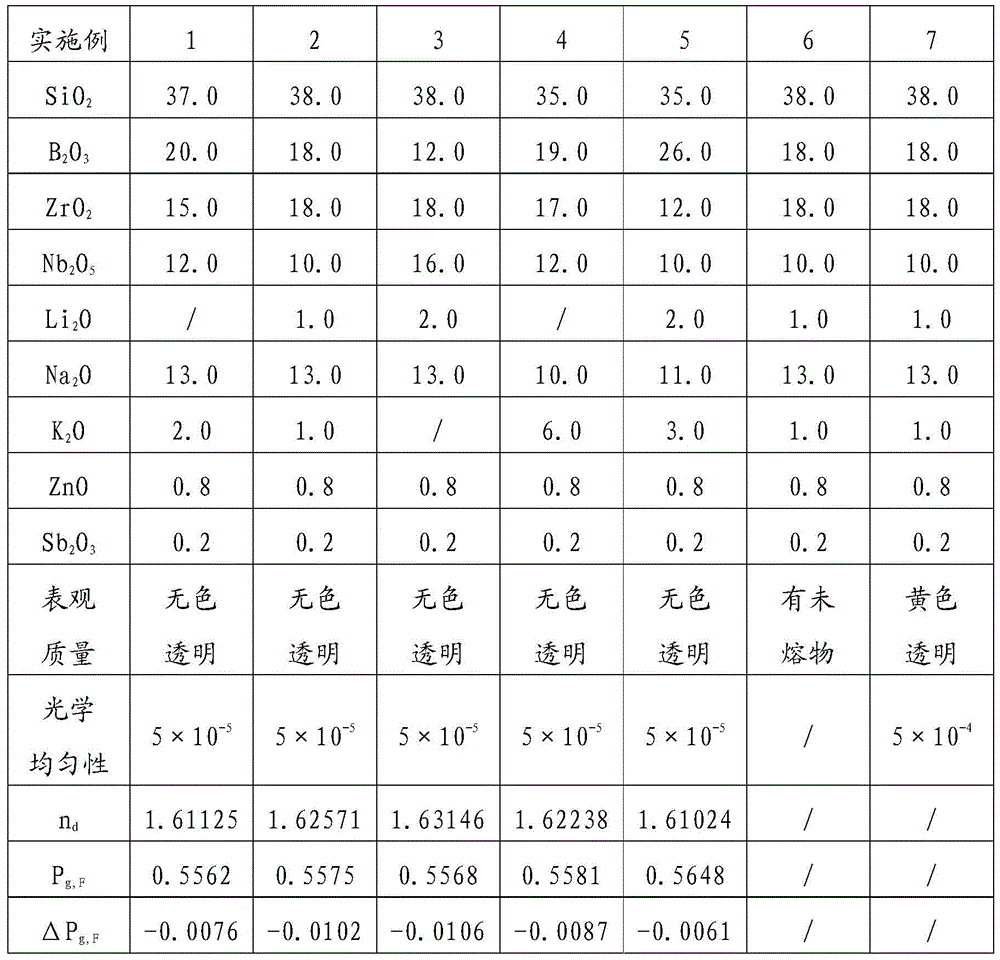

Examples

preparation example Construction

[0025] A preparation method of high zirconium borosilicate glass, comprising the following steps:

[0026] (1) Obtain nano-scale ZrSiO 4 Powder;

[0027] (2) Weigh the raw materials according to the distribution ratio of the glass components, and mix the raw materials evenly to obtain a mixture; in the glass components, ZrO 2 Components based on the ZrSiO 4 Introduced in powder form, SiO 2 Components are ZrSiO 4 The powder and quartz sand are introduced together, and other components are introduced in the form of corresponding oxides, carbonates or nitrates;

[0028] (3) Put the mixed material into the crucible and melt it. After the mixed material is completely melted into glass liquid, then pass O through the pipeline to the bottom of the glass liquid. 2 Carry out bubbling, after bubbling ends, stir by agitator;

[0029] (4) After the temperature is lowered, it is formed by leakage. After the glass is shaped, it is moved into a muffle furnace for annealing to obtain hi...

Embodiment 1

[0049] Raw materials are weighed and batched according to the ratio required in Table 1, and put into a V-shaped mixer for mixing to obtain a mixture, wherein ZrO 2 Nanoscale ZrSiO synthesized by hydrothermal method 4 Powder. Use a Pt crucible to melt at 1450 ° C. After the mixture is completely melted into a glass liquid, high-purity O is introduced to the bottom of the glass liquid through a Pt tube. 2 For bubbling, the flow rate is 0.5L / min, and the time is 1.5h. After bubbling, the molten glass was mechanically stirred with a frame-type Pt stirrer at a speed of 50 rpm for 3 hours. After the temperature is lowered, it is formed by leaking material. After the glass is set, it is moved into a muffle furnace that has been heated to 520°C for annealing for 6 hours. The corresponding high zirconium borosilicate glass is obtained after physical polishing. The relevant properties of the glass are shown in Table 1.

Embodiment 2

[0051] Raw materials are weighed and batched according to the ratio required in Table 1, and put into a V-shaped mixer for mixing to obtain a mixture, wherein ZrO 2ZrSiO synthesized by hydrothermal method 4 Powder. Use a Pt crucible to melt at 1480 ° C. After the mixture is completely melted into a glass liquid, pass high-purity O2 to the bottom of the glass liquid through a Pt tube. 2 For bubbling, the flow rate is 0.8L / min, and the time is 2h. After bubbling, the molten glass was mechanically stirred with a frame-type Pt stirrer at a speed of 60 rpm for 4 hours. After the temperature is lowered, it is formed by leaking material. After the glass is set, it is moved into a muffle furnace that has been heated to 560°C for annealing for 4 hours. The corresponding high zirconium borosilicate glass is obtained after physical polishing. The relevant properties of the glass are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com