Novel ultra-filament mineral cotton

A slag wool and filament technology, applied in glass manufacturing equipment, manufacturing tools, etc., to achieve the effects of good performance, reduced power consumption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

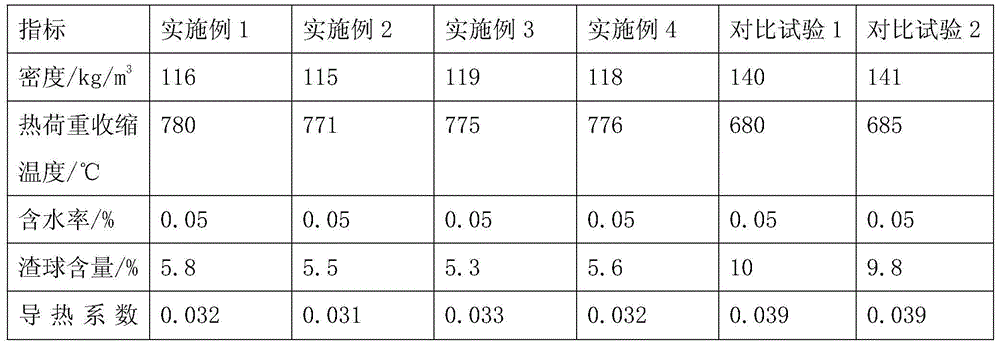

Examples

Embodiment 1

[0024] A kind of production method of novel centrifugal superfilament slag cotton:

[0025] (1) Raw material preparation: blast furnace slag, basalt, fly ash, magnesium oxide, calcium oxide, wollastonite and melt them into a liquid mixture;

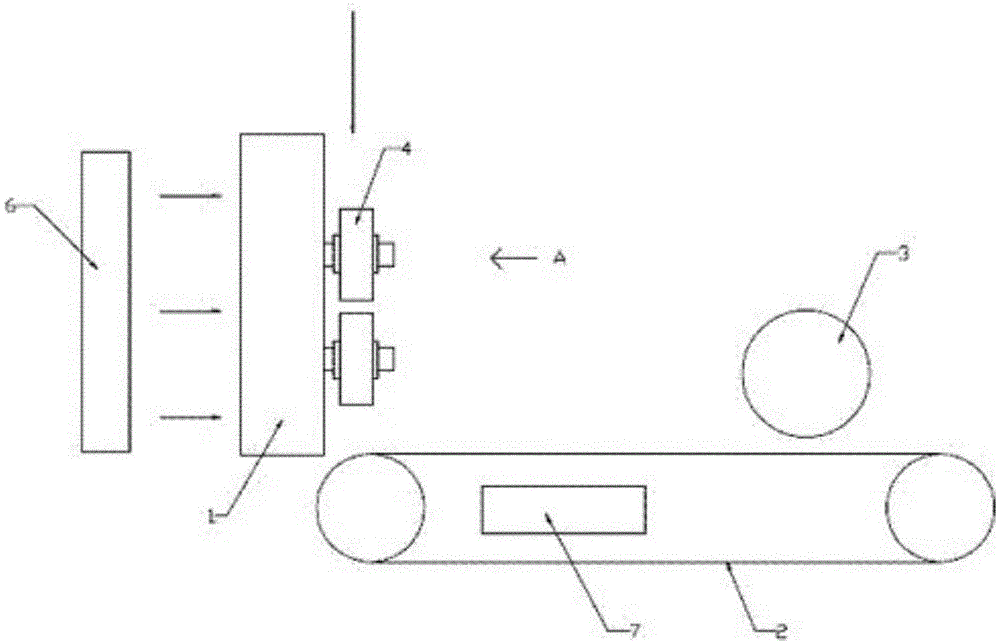

[0026] (2) Fiber preparation: The liquid mixture is continuously flowed into the high-speed rotating centrifugal roller, and the liquid mixture is condensed into filamentous filaments under the action of centrifugal throwing and air cooling, and the filaments are collected and formed under the action of the blower. .

[0027] The (1) raw material components are calculated by weight percentage: 55% of blast furnace slag, 15% of basalt, 6% of fly ash, 3% of magnesium oxide, 2% of calcium oxide, and 19% of wollastonite.

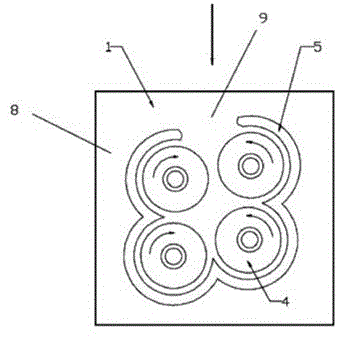

[0028] All the raw materials of step (1) are melted to form a liquid mixture, and the liquid mixture is continuously flowed into the centrifugal rollers rotating at high speed, and the number of centrifugal rollers adopts ...

Embodiment 2

[0030] A kind of production method of novel centrifugal superfilament slag cotton:

[0031] (1) Raw material preparation: blast furnace slag, basalt, fly ash, magnesium oxide, calcium oxide, wollastonite and melt them into a liquid mixture;

[0032] (2) Fiber preparation: The liquid mixture is continuously flowed into the high-speed rotating centrifugal roller, and the liquid mixture is condensed into filamentous filaments under the action of centrifugal throwing and air cooling, and the filaments are collected and formed under the action of the blower. .

[0033] The (1) raw material components are calculated by weight percentage: 64% of blast furnace slag, 12% of basalt, 5% of fly ash, 2% of magnesium oxide, 2% of calcium oxide, and 15% of wollastonite.

[0034] All the raw materials of step (1) are melted to form a liquid mixture, and the liquid mixture is continuously flowed into the centrifugal rollers rotating at high speed, and the number of centrifugal rollers adopts ...

Embodiment 3

[0036] A kind of production method of novel centrifugal superfilament slag cotton:

[0037] (1) Raw material preparation: blast furnace slag, basalt, fly ash, magnesium oxide, calcium oxide, wollastonite and melt them into a liquid mixture;

[0038] (2) Fiber preparation: The liquid mixture is continuously flowed into the high-speed rotating centrifugal roller, and the liquid mixture is condensed into filamentous filaments under the action of centrifugal throwing and air cooling, and the filaments are collected and formed under the action of the blower. .

[0039] The (1) raw material components are calculated by weight percentage: 56% of blast furnace slag, 18% of basalt, 5% of fly ash, 3% of magnesium oxide, 2% of calcium oxide, and 16% of wollastonite.

[0040] All the raw materials of step (1) are melted to form a liquid mixture, and the liquid mixture is continuously flowed into the centrifugal rollers rotating at high speed, and the number of centrifugal rollers adopts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com