Micro-particle sound-insulating plate and preparation method thereof

A sound insulation board and particle technology, applied in the field of particle sound insulation board and its preparation, can solve the problems of reduced sound insulation performance, expensive metal sound insulation materials, and cannot be used directly on exterior walls, and achieves stable chemical properties and good appearance. The effect of quality, good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

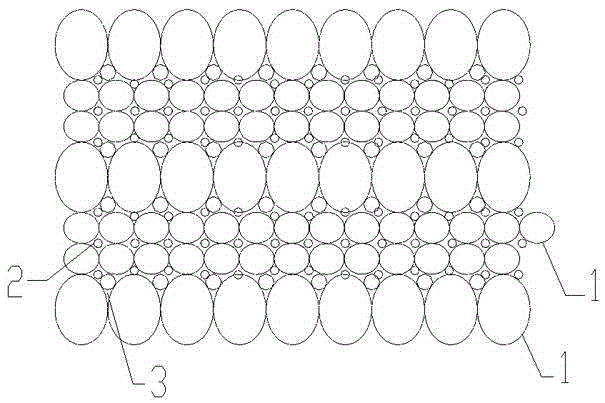

[0035] The preparation method of the particle sound insulation board comprises the following steps:

[0036] (1) Stir and mix the binder pre-added with the coupling agent and the particles of different particle sizes separately, and place it for 0.2-0.5 hours; the particle composition is 40-45 parts of φ0.8mm particles, 40-45 parts of φ0.4mm particles Parts, 3.5-7 parts of φ0.2mm particles, 7-14 parts of φ0.1mm particles; the amount of binder added is 4-6% by weight of particles, and the amount of coupling agent added is 1% by weight of binder -5%; the binder is selected from epoxy resins, phenolic resins, urea-formaldehyde resins and furfuryl alcohol resins, and the coupling agent is selected from silane coupling agents and coupling agents containing isobutyl functional groups.

[0037] (2) Lay a layer of φ0.8mm particle vibration compaction in the mold;

[0038] (3) Lay two layers of φ0.4mm particle vibration compaction in the mold of step (2);

[0039](4) Add φ0.2mm parti...

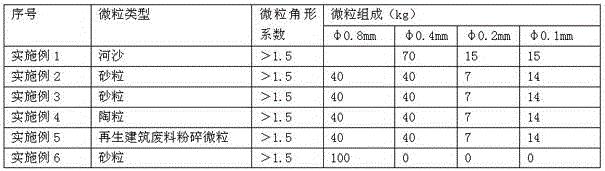

Embodiment 1

[0044] Examples 1, 2, and 6 were prepared by uniformly mixing the particles once, and Examples 3-5 were prepared by the preparation method of the present invention.

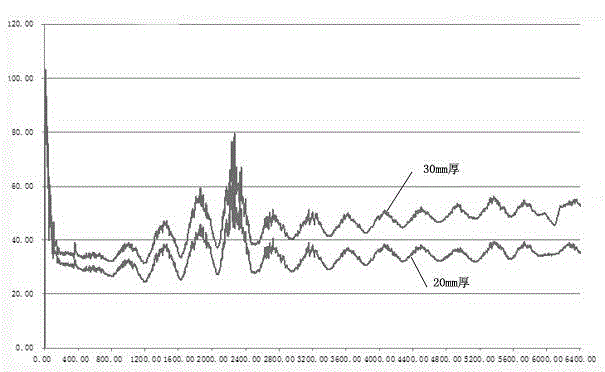

[0045] 2. After testing, the sound insulation and water resistance of the above-mentioned embodiments are shown in the following table:

[0046]

[0047] Therefore, it can be seen from the above table that the particle sound insulation volume of the particle sound insulation board prepared by the method of the present invention meets the requirements of the sound insulation board, and has excellent sound insulation performance, waterproof and anti-corrosion properties. Compared with Example 6 of the particle voids, not only the amount of binder used is greatly reduced, the production cost is reduced, but also the sound insulation is improved. Compared with Examples 1 and 2, which adopt the preparation method of one-time uniform mixing, the sound insulation board prepared by the preparation method of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com