Preparation method of underground filling packing of copper slag ore dressing tail slag iron extraction tailings

A mine tailings technology, which is applied in the field of comprehensive utilization of solid waste, can solve problems such as environmental pollution of tailings, achieve the effects of reducing pollution, realizing economy, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

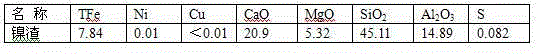

[0019] Table 1 shows the chemical composition of the copper slag used in Example 1, the beneficiation tailings and the iron tailings.

[0020] Table 1 Chemical composition of copper slag beneficiation tailings and iron tailings (%)

[0021]

[0022] At room temperature, the copper slag beneficiation tailings and iron-extracted tailings are mixed evenly with rod grinding according to the mass ratio of 6:4 to form a mixed aggregate of tailings and rod grinding after iron extraction; according to the mass ratio of 1:5.5, 425 cement Add it to the mixed aggregate, mix well, add water to form a slurry with a concentration of 78% by mass, inject the obtained slurry into a mold and make a filling mortar block, which is used for filling in underground mining sites.

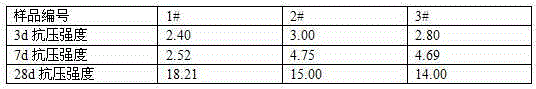

[0023] Table 2 shows the compressive strength test values of the filled mortar blocks 3d, 7d, and 28d.

[0024] Table 2 Compressive strength values of filling block 3d, 7d, 28d (MPa)

[0025]

Embodiment 2

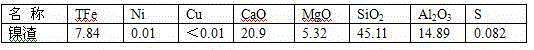

[0027] Table 3 shows the chemical composition of the raw material copper slag ore dressing tailings and iron tailings used in Example 2.

[0028] Table 3 Chemical composition of copper slag beneficiation tailings and iron tailings (%)

[0029]

[0030] At room temperature, the copper slag beneficiation tailings and iron-extracted tailings are mixed evenly with rod grinding according to the mass ratio of 7:3 to form a mixed aggregate of tailings and rod grinding after iron extraction; according to the mass ratio of 1:4, 325 cement Add it to the mixed aggregate, mix well, add water to form a slurry with a concentration of 78% by mass, inject the obtained slurry into a mold and make a filling mortar block, which is used for filling in underground mining sites.

[0031] Table 4 shows the compressive strength test values of filling blocks 3d, 7d, and 28d.

[0032] Table 4 Compressive strength values of filling block 3d, 7d, 28d (MPa)

[0033]

Embodiment 3

[0035] Table 5 shows the chemical composition of the raw material copper slag beneficiation tailings and iron tailings used in Example 3.

[0036] Table 5 Chemical composition of copper slag beneficiation tailings and iron tailings (%)

[0037]

[0038] At room temperature, the copper slag beneficiation tailings and iron-extracting tailings are mixed evenly with rod grinding according to the mass ratio of 7:3 to form a mixed aggregate of tailings and rod grinding after iron extraction; according to the mass ratio of 1:5, 325 cement Or add one of the 425 cements into the mixed aggregate, mix well, add water, form a slurry with a mass percentage concentration of 76%, inject the obtained slurry into a mold, and make a filled mortar block, which is used for underground mining. filling.

[0039] Table 6 shows the compressive strength test values of filling blocks 3d, 7d, and 28d.

[0040] Table 6 Compressive strength values of filling blocks 3d, 7d, and 28d (MPa)

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com