A new process for preparing high-purity isobutene from tert-butanol

A technology of pure isobutene and tert-butanol, which is applied in the chemical industry, can solve the problems of catalyst particles not being fully utilized, catalyst installation and replacement being inconvenient, etc., and achieve the effect of reducing energy consumption and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

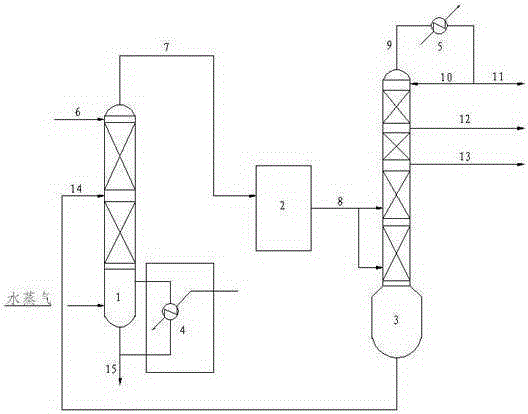

[0028] Vaporization and stripping tower 1 has a theoretical plate number of 25 and an operating pressure of 0.5Mpa (G). The raw material tert-butanol is 3000kg / h, of which tert-butanol is 2400kg / h, water is 600kg / h, and the content of tert-butanol is 80% (Wt).

[0029] The raw material tert-butanol is fed from the top of vaporization stripping tower 1. tert-butanol 240kg / h, water 1183.8kg / h in the mixed solution of the isobutene rectification tower and bottom, the feeding position is the 15th theoretical tray from the first bottom of the vaporization stripping tower, and the steam 7 from the top of the tower is sent to the dehydration In the reaction system, tert-butanol is 2639.8kg / h, water is 293.3kg / h, and tert-butanol content is 89.98% (Wt). The content of tert-butanol in the water discharged from the tower kettle is 0.01% (Wt).

[0030] The isobutene rectification tower is a plate tower with an operating pressure of 0.45Mpa(G), 28 theoretical plates, 240kg / h of tert-but...

Embodiment 2

[0032] Vaporization and stripping tower 1 has a theoretical plate number of 20 and an operating pressure of 0.5Mpa (G). The raw material tert-butanol is 2000kg / h, of which tert-butanol is 1900kg / h, water is 100kg / h, and the content of tert-butanol is 95% (Wt).

[0033] The raw material tert-butanol is fed from the top of vaporization stripping tower 1. 152kg / h of tert-butanol and 525.2kg / h of water in the mixed solution of the isobutene rectification tower and bottom, the feeding position is the 10th theoretical plate from the first bottom of the vaporization stripping tower, and the steam 7 from the top of the tower is sent to dehydration In the reaction system, tert-butanol is 1853kg / h, water is 18.7kg / h, and tert-butanol content is 99.0% (Wt). The content of tert-butanol in the water discharged from the tower kettle is 0.008% (Wt).

[0034]The isobutene rectification tower is a plate tower with an operating pressure of 0.45Mpa(G), 15 theoretical plates, 152kg / h of tert-bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com