Environment-friendly low-formaldehyde wastewater-discharge-free furan resin and preparation method thereof

A furan resin, no waste water technology, used in manufacturing tools, casting and molding equipment, metal processing equipment, etc., can solve the problems of intractable treatment, environmental pollution, and high free formaldehyde content, reducing the content of free formaldehyde and reducing the volatilization of formaldehyde. , the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

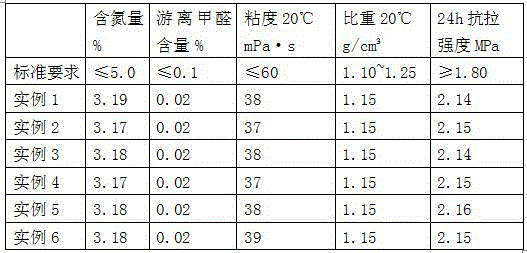

Examples

Embodiment 1

[0024] In parts by weight, 34 parts of tap water, 56 parts of furfuryl alcohol, 14 parts of formaldehyde, 10 parts of urea, 0.3 parts of ammonia water, 0.3 parts of formic acid, 0.3 parts of sodium hydroxide, N-β-aminoethyl-γ-aminopropyl methyl 0.4 parts of methyl dimethyl silane, 4 parts of methanol.

[0025] Among them, formaldehyde is solid formaldehyde with a content of ≥95%, and the concentration of ammonia water is 25-35%. The present invention uses one of N-β-aminoethyl-γ-aminopropylmethyldimethylsilane, γ-aminopropyltriethoxysilane, and γ-glycidyl etheroxypropyltrimethoxysilane as a coupling agent. (the same below)

[0026] Preparation:

[0027] 1) Feeding: First add 30 parts of water to the reaction kettle, then add 14 parts of formaldehyde and 9 parts of urea, stir well, and then slowly add sodium hydroxide to adjust the pH value to 8.5.

[0028] 2) After raising the temperature to 90°C, keep it warm for 40 minutes, then add 1 part of urea and 33 parts of furfury...

Embodiment 2

[0035] In parts by weight, take 30 parts of treated waste water, 4 parts of tap water, 56 parts of furfuryl alcohol, 13 parts of formaldehyde, 10 parts of urea, 0.3 parts of ammonia, 0.3 parts of formic acid, 0.3 parts of sodium hydroxide, N-β-aminoethyl - 0.4 parts of γ-aminopropylmethyldimethylsilane, 4 parts of methanol.

[0036] Preparation:

[0037] 1) Feeding: First add 30 parts of treated waste water to the reactor, then add 13 parts of formaldehyde and 9 parts of urea, stir well, and then slowly add sodium hydroxide to adjust the pH value to 8.

[0038] 2) After heating up to 90°C, keep warm for 40 minutes, then add 1 part of urea and 33 parts of furfuryl alcohol, and slowly add sodium hydroxide to adjust the pH to 8.

[0039] 3) Raise the temperature to 90°C, keep it warm for 30 minutes, and vacuum dehydrate after the end.

[0040] 4) Add 23 parts of furfuryl alcohol and slowly add formic acid to adjust the pH value to 5.

[0041] 5) Raise the temperature to 105°C,...

Embodiment 3

[0045] In parts by weight, take 28 parts of treated waste water, 3 parts of tap water, 54 parts of furfuryl alcohol, 11 parts of formaldehyde, 9 parts of urea, 0.25 parts of ammonia, 0.25 parts of formic acid, 0.25 parts of sodium hydroxide, γ-aminopropyl triethyl 0.4 parts of oxysilane, 3 parts of methanol.

[0046] Preparation:

[0047] 1) Feeding: First add 28 parts of treated waste water to the reactor, then add 11 parts of formaldehyde and 8 parts of urea, stir well, and then slowly add sodium hydroxide to adjust the pH value to 9.

[0048] 2) After heating up to 85°C, keep warm for 60 minutes, then add 1 part of urea and 32 parts of furfuryl alcohol, and slowly add sodium hydroxide to adjust the pH value to 9.

[0049] 3) Raise the temperature to 90°C, keep it warm for 40 minutes, and vacuum dehydrate after the end.

[0050] 4) Add 22 parts of furfuryl alcohol and slowly add formic acid to adjust the pH value to 4.

[0051] 5) Raise the temperature to 90°C, keep it wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com