Castor oil modified weak cation polyurethane color fixing agent and preparation method thereof

A technology of weak cations and castor oil, which is applied in dyeing, textiles and papermaking to achieve the effects of improving color fastness, enhancing binding fastness and cohesive force, and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

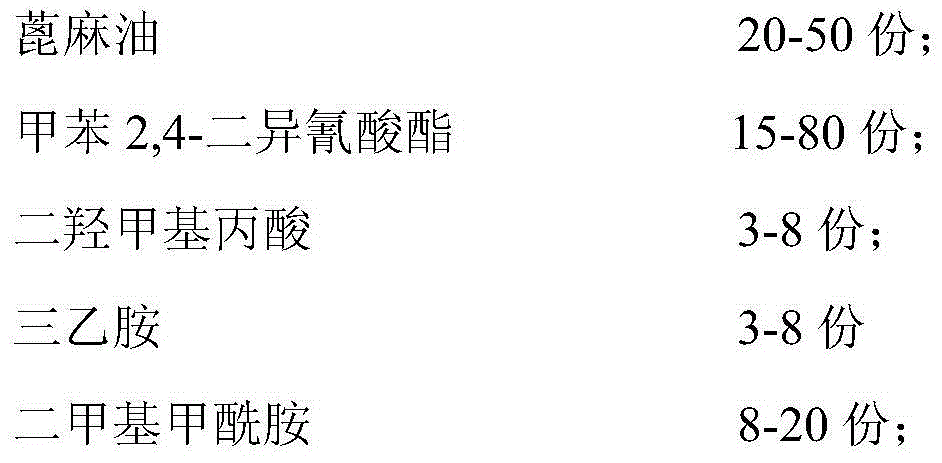

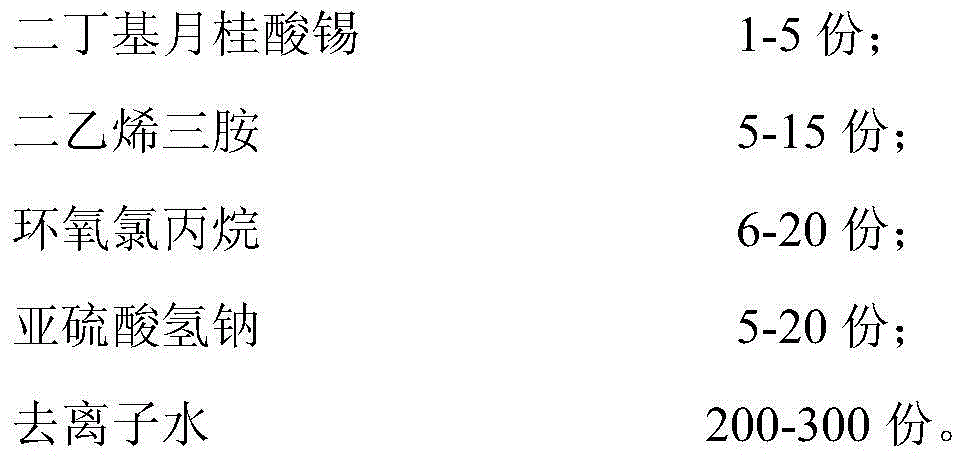

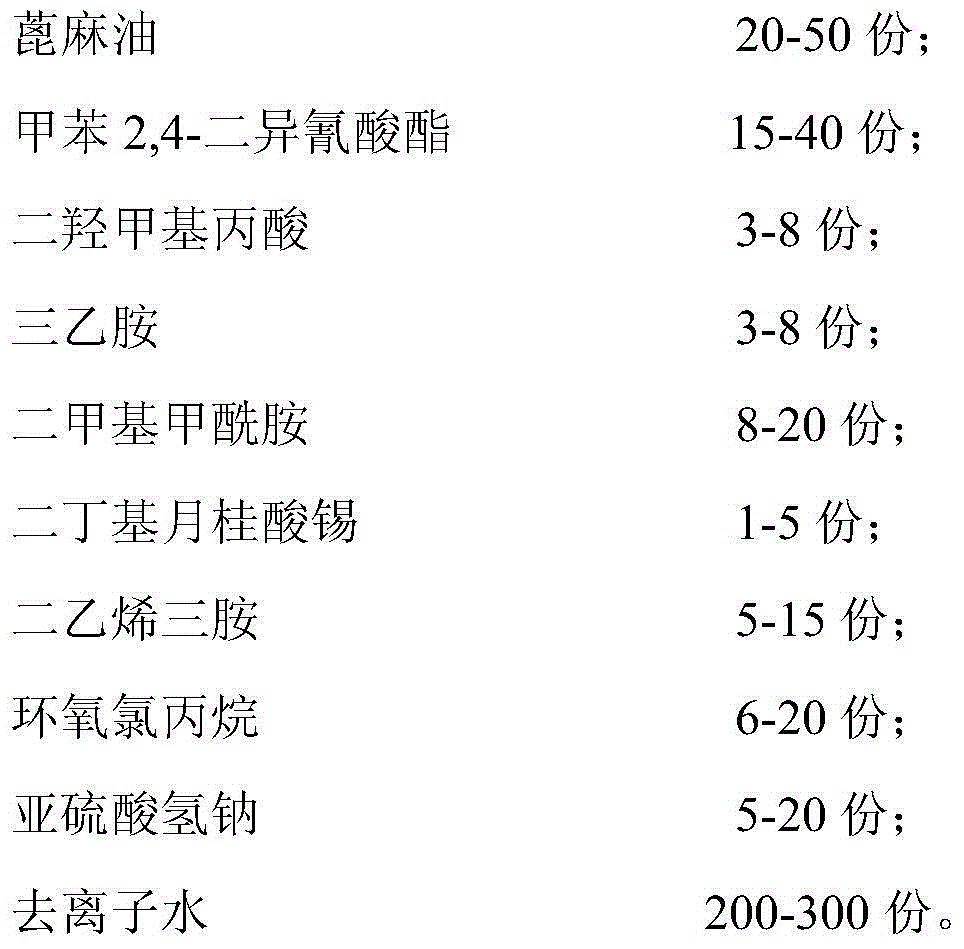

Method used

Image

Examples

Embodiment 1

[0027] (1) Prepolymerization of polyurethane:

[0028] Add 50 parts of castor oil into the dry reaction kettle, heat up to 110-120°C, dehydrate for 2 hours under vacuum degree of 0.05MPa, add 1 part of dibutyltin laurate (DBTL) under the protection of dry nitrogen, keep warm at about 75°C, drop Add 60 parts of TDI, keep it warm for about 3 hours, cool down to 50°C, and add 20 parts of acetone to dilute.

[0029] (2) Polyurethane introduces hydrophilic groups and chain extension and neutralization reactions:

[0030] Add 8 parts of 2,2-dimethylolpropionic acid (DMPA) in dimethylformamide (DMF) solution for chain extension, introduce hydrophilic groups, control the temperature at 50°C, and react until the content of -NCO groups After reaching the theoretical value, slowly add 7.5 parts of triethylamine for neutralization, and react for 4 hours, wherein the amount of DMF is 15 parts.

[0031] (3) Polyurethane chain extension reaction:

[0032] Add 10 parts of diethylenetriamin...

Embodiment 2

[0041] (1) Prepolymerization of polyurethane:

[0042] Add 20 parts of castor oil into the dry reaction kettle, raise the temperature to 110-120°C, dehydrate for 2 hours under vacuum degree of 0.05MPa, add 3 parts of dibutyltin laurate (DBTL) under the protection of dry nitrogen, keep warm at about 75°C, drop Add 15 parts of TDI, keep it warm for about 3 hours, cool down to 50°C, and add 20 parts of acetone to dilute.

[0043] (2) Polyurethane introduces hydrophilic groups and chain extension reaction:

[0044] Add 3 parts of 2,2-dimethylolpropionic acid (DMPA) in dimethylformamide (DMF) solution for chain extension, introduce hydrophilic groups, control the temperature at 50°C until the content of -NCO groups reaches The theoretical value, then slowly add 3 parts of triethylamine, react for about 4 hours, and the amount of DMF is 20 parts.

[0045] (3) Polyurethane chain extension reaction:

[0046] Add 5 parts of diethylenetriamine for chain extension, the reaction temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com