Degradable porous poly lactic acid preparation method

A technology of polylactic acid and polyglutamic acid, which is applied in the direction of medical preparations and pharmaceutical formulas of non-active ingredients, to achieve the effects of good biocompatibility, reduced toxic and side effects, and high drug load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] ①Preparation of star block copolymer

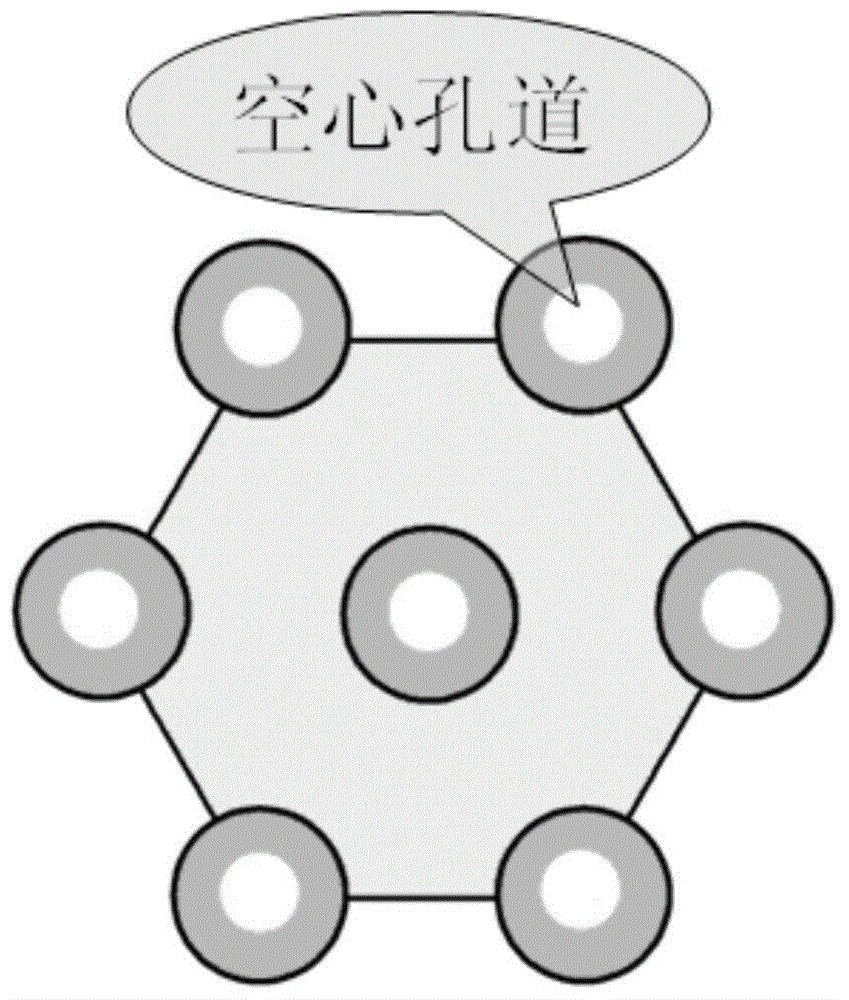

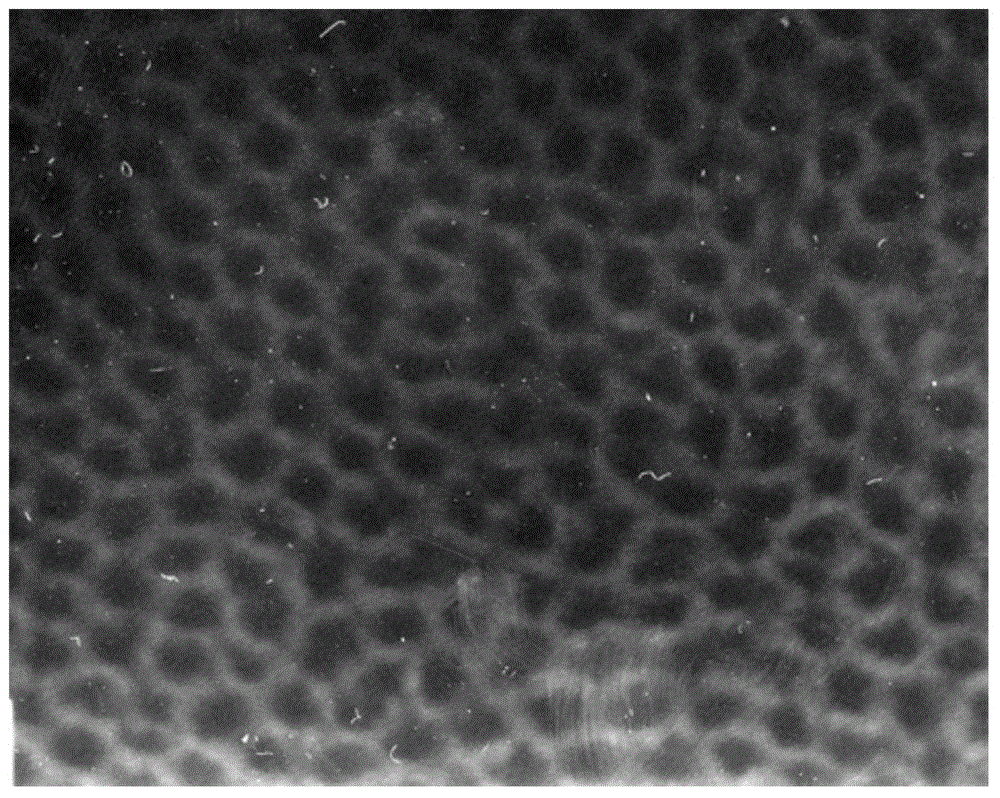

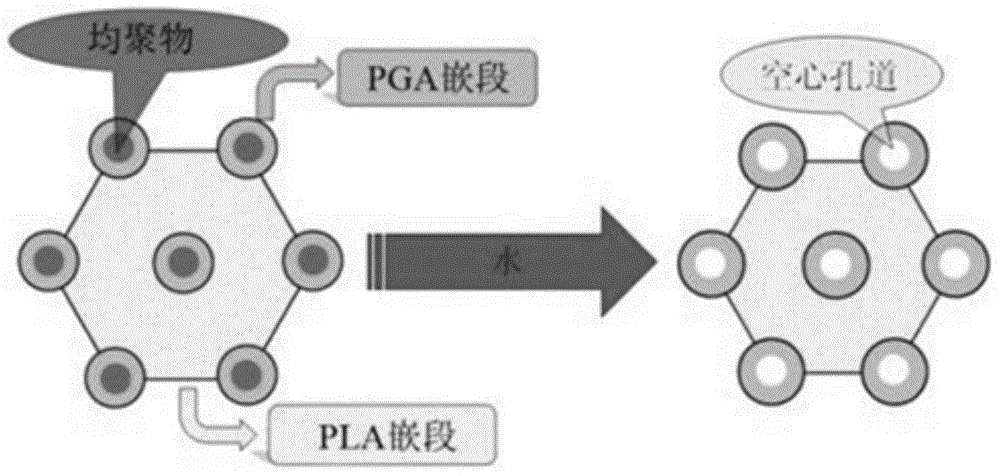

[0028] Using L-lactide as raw material, three-arm or multi-arm star polylactic acid was synthesized by the classic stannous octoate catalyzed ring-opening method. Due to the presence of hydroxyl groups at the end of the polymer, glycine protected by amino Boc-groups can be used , under the catalysis of DCC / HOBt, react with SPLA to generate SPLA derivatives, in trifluoroacetic acid / dichloromethane solution, carry out the amino de-Boc protection of the above product, and obtain the star-shaped macromolecular initiator SPLA-NH of the amino-terminated functional group 2 . The macroinitiator and benzyl glutamate carboxylic acid anhydride (NCA) were subjected to ring-opening polymerization at a certain ratio to obtain a star-shaped block polymer with PLA as the core and PBLG as the arm. Finally, the benzyl protecting group was hydrolyzed by HBr, AcOH and trifluoroacetic acid mixed solution to finally obtain the star-shaped polylactic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com