Method for improving fermentation yield of nemadectin

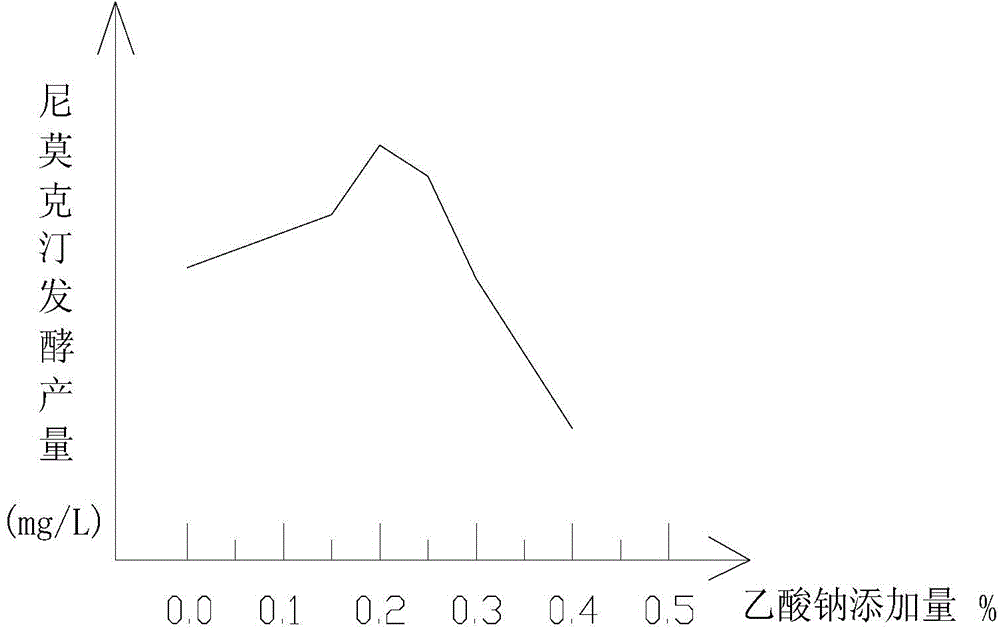

A technology for improving the yield of nimoctine, which is applied in the field of increasing the yield of fermented nemoctine, can solve the problems of the yield to be increased and the low yield of nemoctine, and achieve the effect of increasing the yield and increasing the fermented yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 115

[0023] In embodiment 1.1.5T fermentor fermentation process, do not add sodium acetate

[0024] A. Select the starting strain: select a sodium acetate-resistant Streptomyces chromogenes mutant strain, and the taxonomic name of the sodium acetate-resistant Streptomyces chromogenes mutant strain is Streptomyces cyanneorisens DC18-01 , preserved in the China Microorganism Culture Collection Management Committee, the preservation number is CGMCC No.6217, and the preservation date is June 14, 2012;

[0025] B. Strain slant culture: Inoculate Streptomyces cyanneorisens DC18-01 on the slant medium, and culture it at 26-30°C and 30%-60% humidity for 96-144h to obtain the slant strain;

[0026] C. Strain bottle culture: dig 2-5cm 2 The slant strain prepared in step B is inoculated in the medium of the seed bottle, and cultured with shaking at 26-30°C and 220-240rpm for 24-30h to obtain a mature seed solution;

[0027] D, seed tank culture: inoculate the mature seed solution obtained i...

Embodiment 215

[0029] Example 2.1.5T fermenter fermentation process added sodium acetate 168h after the start of fermentation

[0030] A. Select the starting strain: select a sodium acetate-resistant Streptomyces chromogenes mutant strain, and the taxonomic name of the sodium acetate-resistant Streptomyces chromogenes mutant strain is Streptomyces cyanneorisens DC18-01 , preserved in the China Microorganism Culture Collection Management Committee, the preservation number is CGMCC No.6217, and the preservation date is June 14, 2012;

[0031] B. Strain slant culture: Inoculate Streptomyces cyanneorisens DC18-01 on the slant medium, and culture it at 26-30°C and 30%-60% humidity for 96-144h to obtain the slant strain;

[0032] C. Strain bottle culture: dig 2-5cm 2 The slant strain prepared in step B is inoculated in the medium of the seed bottle, and cultured with shaking at 26-30°C and 220-240rpm for 24-30h to obtain a mature seed solution;

[0033] D, seed tank culture: inoculate the mature...

Embodiment 312

[0035] Example 3. In the fermentation process of 12T fermenter, sodium acetate A was added 168h and 216h after the start of fermentation, and the starting strain was selected: a sodium acetate-resistant Streptomyces chromogenes mutant strain was selected, and the sodium acetate-resistant color-producing strain was selected. The taxonomic name of the Streptomyces mutant strain is Streptomyces cyanneorisens DC18-01, which was deposited in the China Committee for the Collection of Microorganisms with a preservation number of CGMCC No.6217 and a preservation date of June 14, 2012;

[0036] B. Strain slant culture: Inoculate Streptomyces cyanneorisens DC18-01 on the slant medium, and culture it at 26-30°C and 30%-60% humidity for 96-144h to obtain the slant strain;

[0037] C. Strain bottle culture: dig 2-5cm 2 The slant strain prepared in step B is inoculated in the medium of the seed bottle, and cultured with shaking at 26-30°C and 220-240rpm for 24-30h to obtain a mature seed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com