Heat treatment method for low-loss and medium and high-frequency iron-based nanocrystalline transformer iron cores

An iron-based nanocrystal and transformer core technology, applied in the field of heat treatment, can solve the problems of low average value, poor economic indicators, relatively large fluctuations in heat release and punch temperature values, and reduce production costs and product qualification rates. High and cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

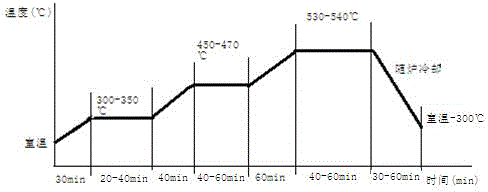

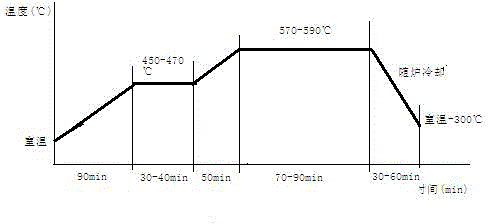

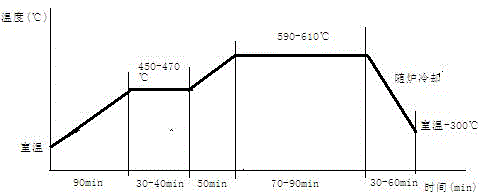

[0018] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. like Figure 1 to Figure 3 Shown:

[0019] Iron-based nanocrystalline strips with a thickness of 27±4μm produced in batches are used to wind iron cores according to the required dimensions and weight, and the space factor of the iron cores is ≥75%. Conduct the first heat treatment on the above-mentioned iron core with the qualified iron core in nitrogen or argon protective atmosphere or vacuum environment. The first heat treatment adopts three-stage heat preservation method, of which the temperature of the first stage is 300-350 ℃, heat preservation The time is 20-40min, the temperature of the second stage is 450-470°C, the holding time is 40-60min, the temperature of the third stage is 530-540°C, the holding time is 40-60min, and then the iron core is kept within 30-60min. The furnace is cooled to room temperature to 300°C, and the first he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com