Full section mixing and cutting wall making machine

A wall-building machine and full-section technology, which is applied to sheet pile walls, earth movers/excavators, water conservancy projects, etc., can solve the problems of affecting soil retaining and water interception effects, uneven upper and lower strength, and limited frame height, etc. Problems, to achieve high promotion and application value, good lapping effect, and mature accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

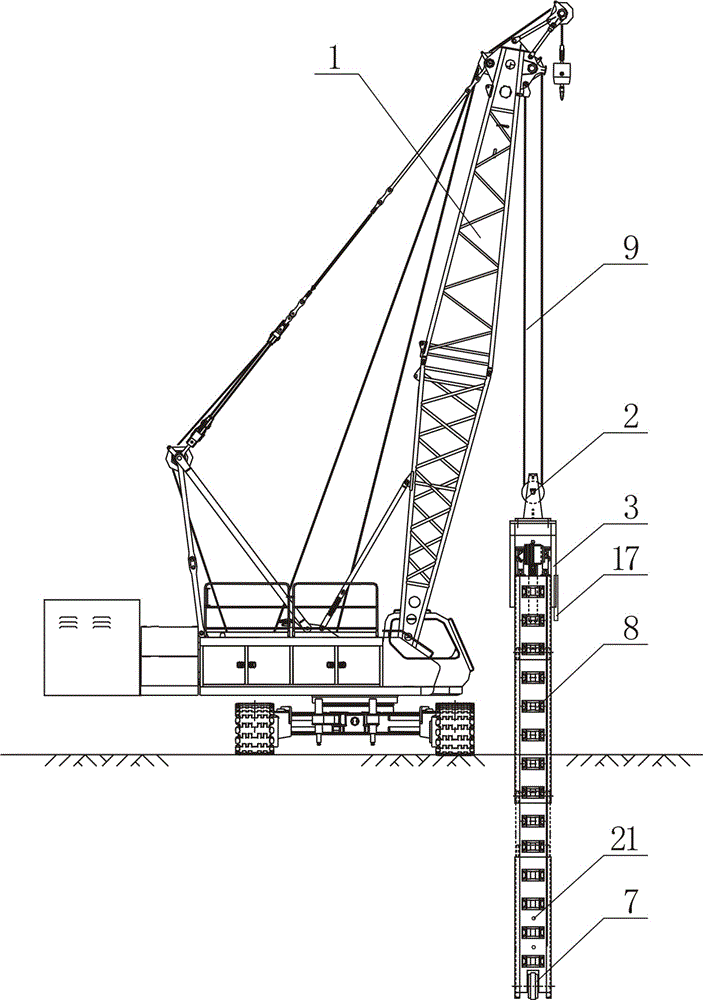

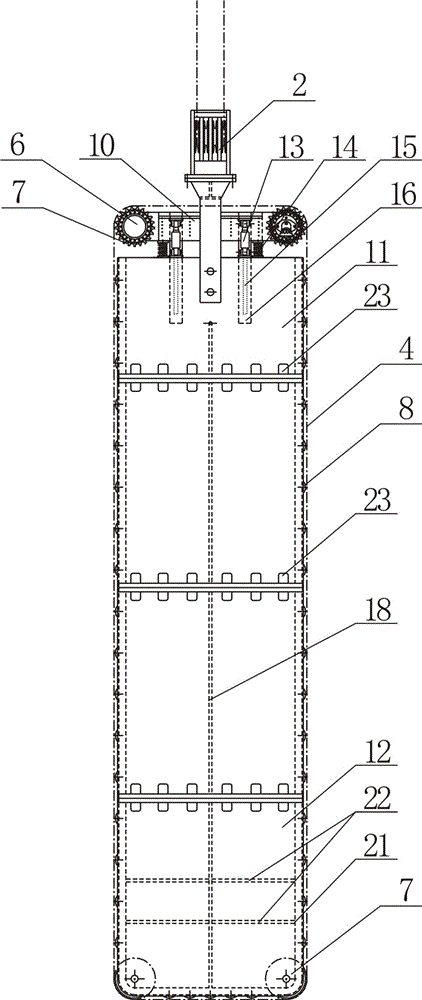

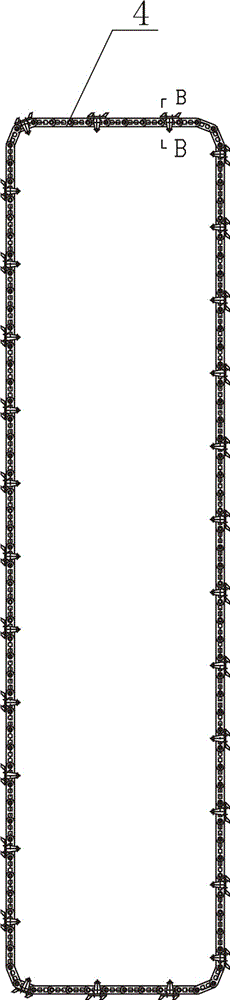

[0027] Such as figure 1 , 2 As shown, the full-section mixing and cutting wall building machine is mainly composed of a crawler crane 1, a pulley block 2, a chain turning device and a grouting pipe 18. , motor 6, the grouting pipe 18 is arranged on the rectangular chain bracket 3, the lower end of the grouting pipe 18 is connected with two grouting branch pipes 22, the grouting branch pipe 22 is connected to the rectangular chain bracket 3 two The grouting port 21 on the side wall communicates. The cement slurry is discharged through the grouting port 21. The four corners of described rectangular chain support 3 are provided with sprocket wheel 7, and the both sides of rectangular chain support 3 and the bottom are distributed with a plurality of guide wheels 8, and described chain 4 is arranged on described sprocket wheel 7 and guide wheel 8, The plurality of cutters 5 are distributed on the surface of the chain 4 at intervals. The crawler crane 1 is connected to the pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com