Exhaust gas recirculation apparatus of engine with supercharger

A technology of exhaust gas recirculation and supercharger, which is applied in the direction of machine/engine, engine components, engine control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

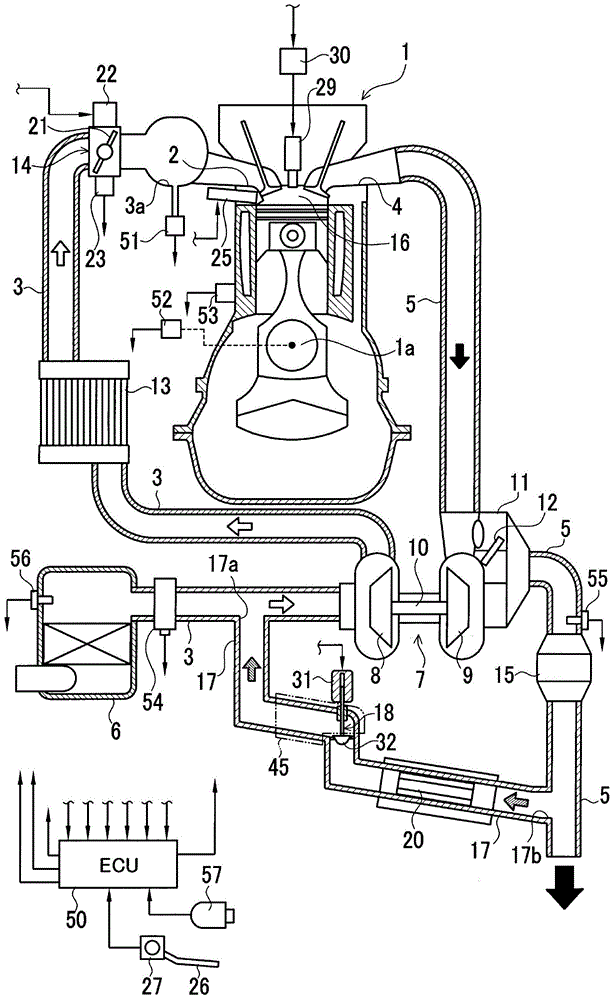

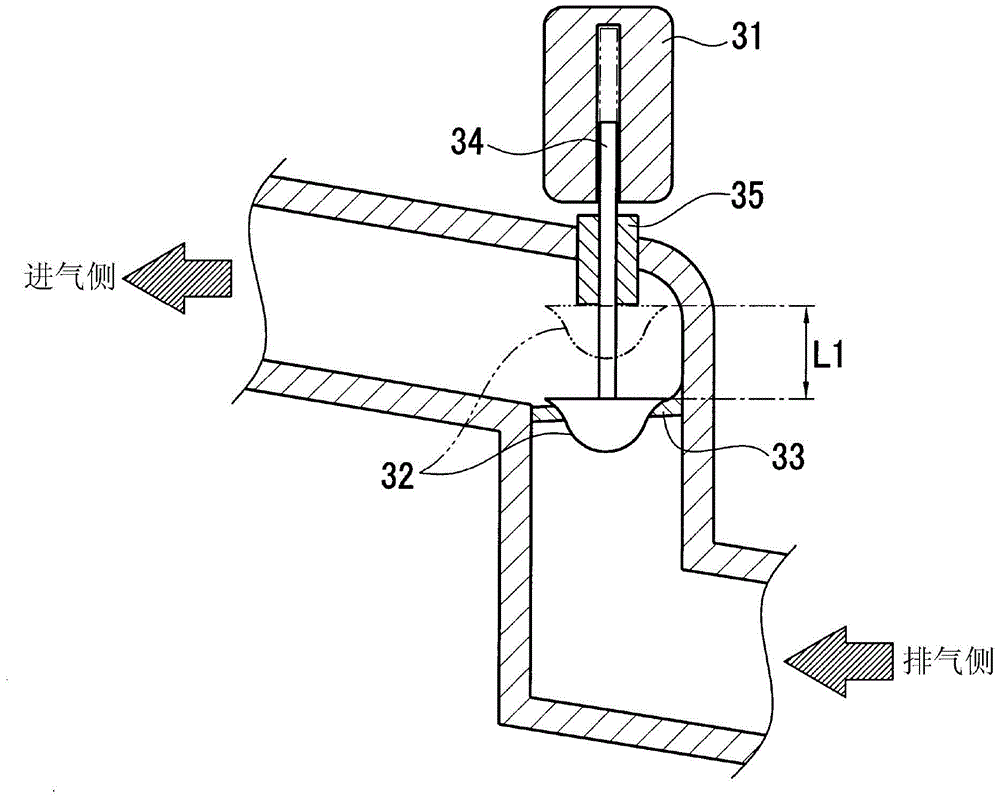

[0071] Hereinafter, a first embodiment embodying an exhaust gas recirculation device for an engine with a supercharger according to the present invention will be described in detail with reference to the drawings.

[0072] figure 1 A gasoline engine system including an exhaust gas recirculation device (EGR device) of an engine with a supercharger according to this embodiment is shown by a schematic configuration diagram. The engine system includes a reciprocating engine 1 . The intake port 2 of the engine 1 is connected to the intake passage 3 , and the exhaust port 4 is connected to the exhaust passage 5 . An air filter 6 is provided at the inlet of the intake passage 3 . On the intake passage 3 downstream of the air filter 6, a supercharger 7 is provided, and the supercharger 7 is used to make the intake air in the intake passage 3 between the intake passage 3 and the exhaust passage 5 Boost.

[0073] The supercharger 7 includes a compressor 8 arranged in the intake pas...

no. 2 Embodiment approach

[0106] Next, a second embodiment embodying an exhaust gas recirculation device for an engine with a supercharger according to the present invention will be described in detail with reference to the drawings.

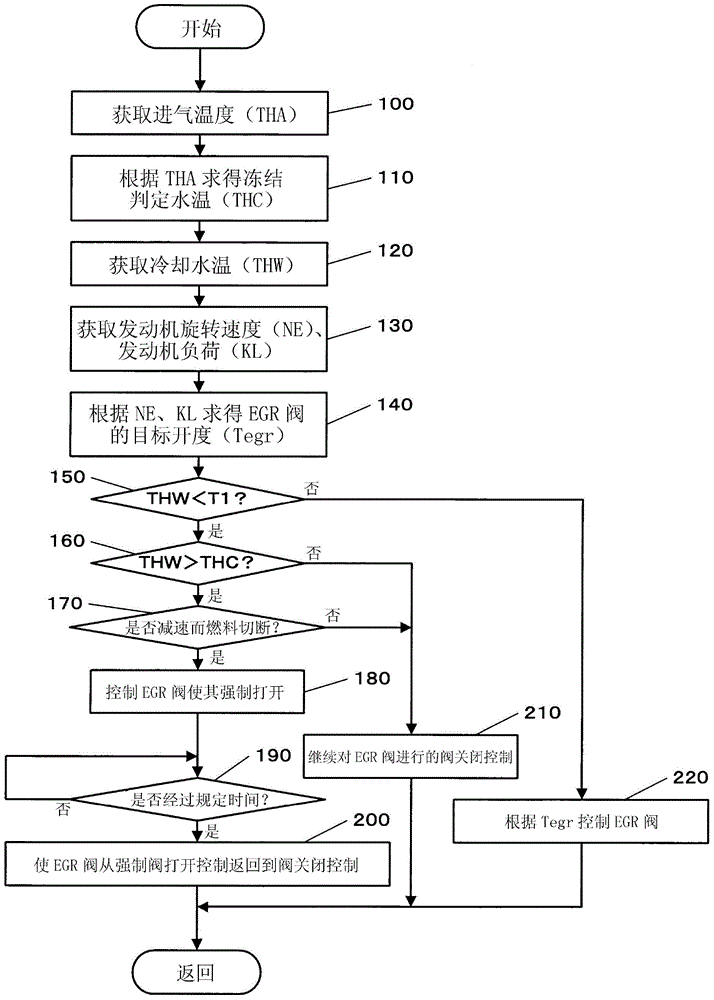

[0107] In addition, in each embodiment described below, the same code|symbol is attached|subjected to the structural element equivalent to the said 1st Embodiment, and description is abbreviate|omitted, and it demonstrates centering on a difference.

[0108] This embodiment differs from the configuration of the first embodiment in terms of the processing content of the condensed water discharge control. Figure 5 An example of the processing content of the condensed water discharge control of this embodiment is shown by the flowchart in FIG. exist Figure 5 In the flow chart of the image 3 The flow diagrams are different: except for image 3 In addition to the processing of the flowchart, the processing of step 165 is provided between step 160 and step 170, the proce...

no. 3 Embodiment approach

[0116] Next, a third embodiment embodying an exhaust gas recirculation device for an engine with a supercharger according to the present invention will be described in detail with reference to the drawings.

[0117] This embodiment differs from the configuration of the second embodiment in terms of the processing content of the condensed water discharge control. Figure 6 An example of the processing content of the condensed water discharge control of this embodiment is shown by the flowchart in FIG. exist Figure 6 In the flowchart of Figure 5 The processing of the flow chart is similar in that the processing of step 135 is provided instead of the processing of step 130, and the processing of steps 250 and 260 is newly provided. Figure 5 The flow chart is different.

[0118] After switching the processing to this routine and executing the processing of steps 100 to 120, in step 135, the ECU 50 obtains the engine rotational speed NE, Engine load KL and intake gas Ga.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com