A remote positioning and flipping system for replacing target inserts

A target body and plug-in technology, applied in the field of target body plug-in remote control maintenance system, can solve the problems of time-consuming manpower, material resources, occupation of shielding barrel space, and high degree of activation, so as to improve safety and stability and ensure reliability. With the effect of safety, simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

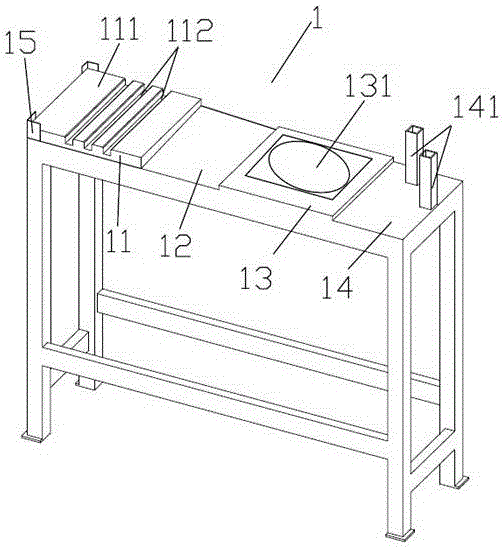

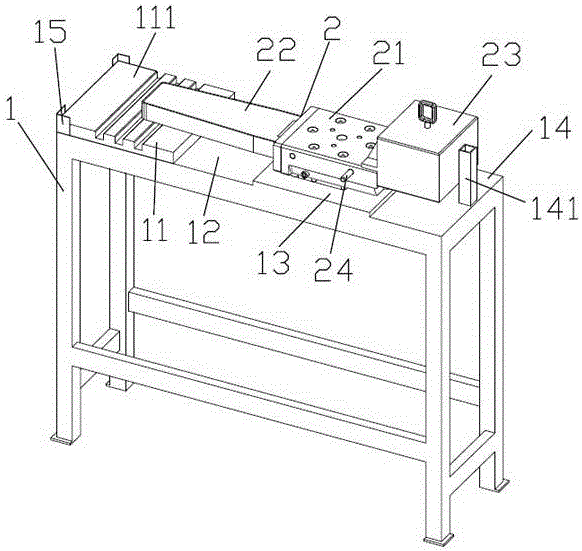

[0028] A remote positioning and overturning system for replacing target inserts. The remote positioning and overturning system is set in a closed hot room environment and mainly includes a monitoring system, auxiliary tools and target inserts 2. The remote positioning and overturning system It also includes positioning and turning workbench 1, which is mainly composed of a rectangular workbench and a support frame fixedly connected. The surface structure of the workbench matches the structure of the bottom surface of the target insert 2. There are four steps to the right, wherein the first step 11 is a cast iron boss 111 that protrudes upwards along the surface of the workbench, and a slender groove 112 is opened in the middle of the cast iron boss 111, and the slender groove 112 opened by the cast iron boss 111 The depth parameter of the groove 112 is 1 / 3-1 / 2 of the height parameter of the cast iron boss, the second step 12 and the fourth step 14 are on the same horizontal pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com