Time-frequency diagram processing method and system for mechanical equipment monitoring vibration signals

A technology of vibration signal and processing method, which is applied in the field of diagnosis and mechanical equipment fault monitoring, and can solve problems such as difficult real-time diagnosis of faults, inability to apply, long storage time of huge amounts of data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

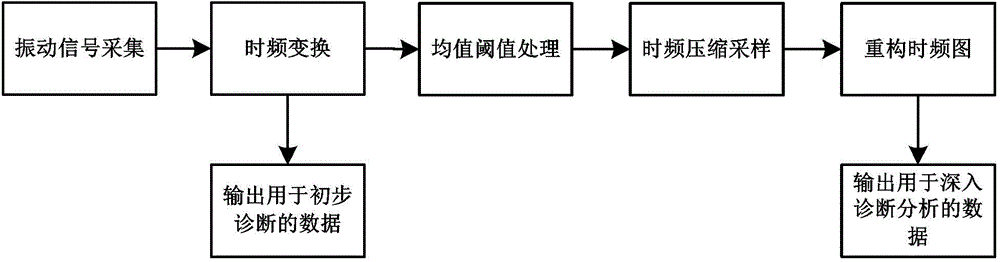

[0060] Embodiments of the time-frequency diagram processing method and system for monitoring vibration signals of the mechanical equipment are further described in detail below with reference to the accompanying drawings.

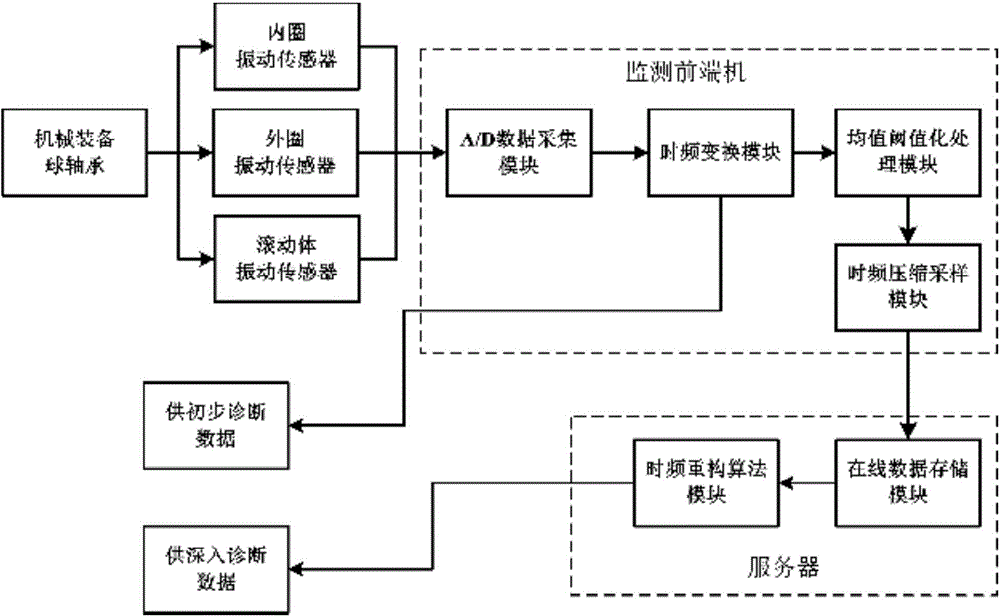

[0061] Embodiment of time-frequency map processing system for mechanical equipment monitoring vibration signal

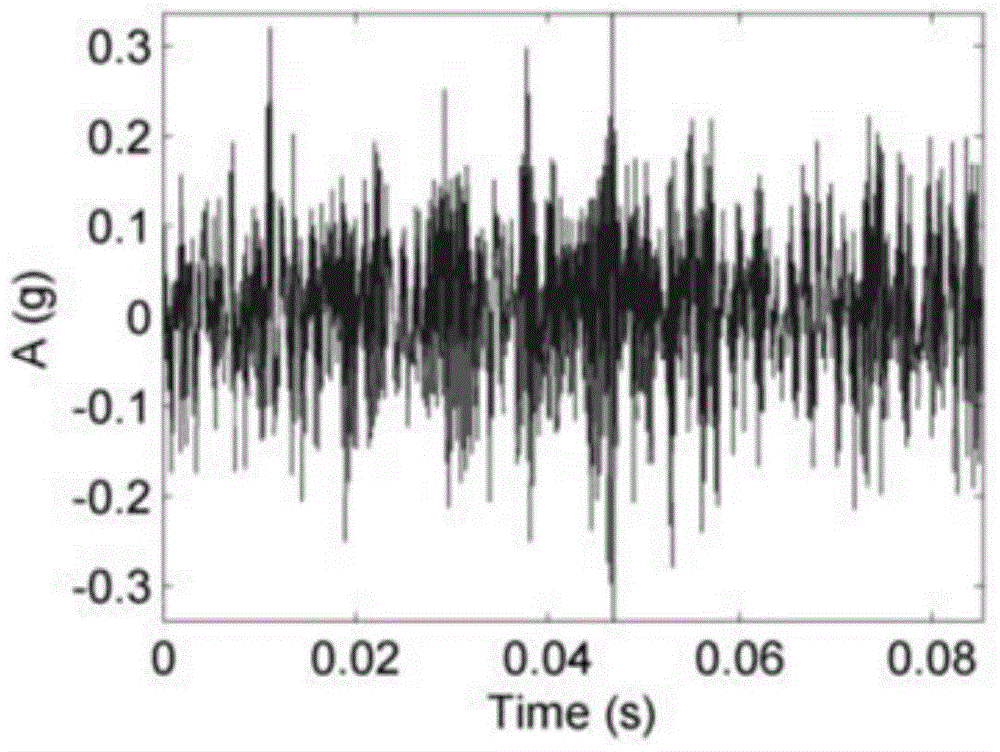

[0062] Rolling bearings are key components in mechanical equipment. However, rolling bearings may be damaged due to various reasons during operation, such as improper assembly, poor lubrication, moisture and foreign matter intrusion, corrosion and overloading, etc., which may lead to premature failure of rolling bearings. Even if the installation, lubrication and maintenance are normal, after a period of operation, the rolling bearing will experience fatigue spalling, wear, pitting and other faults, resulting in failure to work normally.

[0063] The embodiment of the time-frequency diagram processing system for monitoring vibration signals of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com